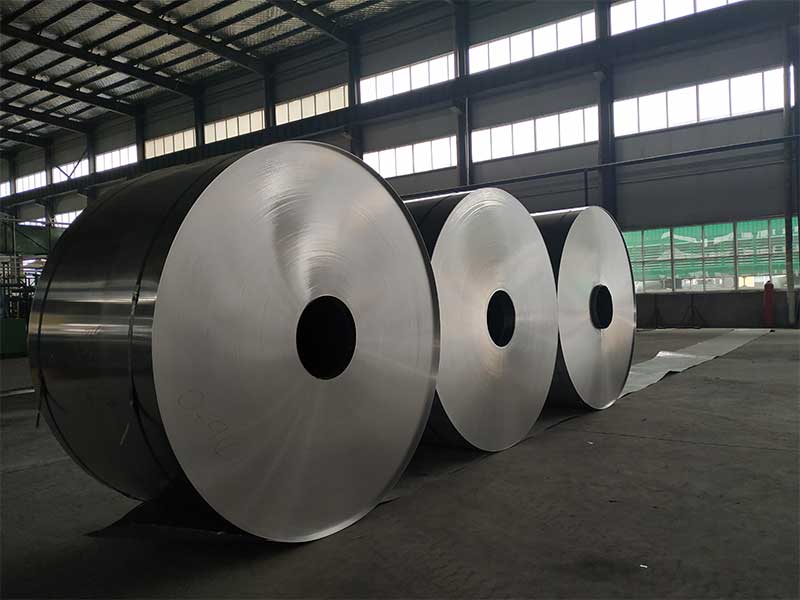

0.3mm-6.0mm Thickness Mill Finish Aluminium Coil

Aluminium has long been recognized as one of the most versatile and adaptive materials in manufacturing and construction. Among its varied forms, the 0.3mm-6.0mm thickness mill finish aluminium coil stands out for its flexibility, durability, and ease of use. With a host of applications across different sectors, understanding its features will help highlight why this product is indispensable.

Features of Mill Finish Aluminium Coil

-

Varied Thickness Range: The key feature of the 0.3mm-6.0mm thickness range is the precision it offers. This flexibility allows designers and engineers to choose the exact specification their application demands, whether that’s for lightweight projects or more robust needs.

-

Natural Finish: The mill finish on aluminium coil means it is delivered with a slightly rough surface. While natural, this finish offers enhanced structural integrity and can easily be further treated for additional functionality including painting, anodizing, or coating.

-

Lightweight yet Durable: Aluminium is known for its impressive strength-to-weight ratio. This quality makes the 0.3mm-6.0mm thickness mill finish aluminium coil incredibly effective for projects that require durability without the added weight—ideal for reducing strain in structural applications.

-

Corrosion Resistance: One of the standout features of aluminium is its inherent corrosion resistance. Whether exposed to a range of environmental factors or used in industries that require hygienic conditions, this material holds strong against rust, enhancing its practicality.

-

Customizable and Versatile: The coil form allows for extensive customization in length and shape, enabling seamless integration into a wide array of projects while maintaining efficiency in manufacturing and logistics.

Applications of Mill Finish Aluminium Coil

-

Construction Industry: Architecturally appealing and structurally sound, mill finish aluminium coils are extensively used in building facades, roofing systems, and interior decorations. Their aesthetic qualities combined with practical attributes make them a go-to option for modern architectural designs.

-

Automotive Components: In the automotive sector, the lightweight nature of this aluminium coil helps improve fuel efficiency while maintaining the sturdiness required for various vehicle parts, including body panels and structural elements.

-

Manufacturing Processes: Manufacturers prefer using mill finish aluminium coils in making various products, such as consumer electronics enclosures, packaging trays, and durable appliance components, due to their excellent thermal conductivity and resistance to heat.

-

Transportation Fleet: For aerospace and marine applications, where every ounce matters, employing such aluminium coils ensures vehicles maintain optimum balance and functionality without adding unnecessary weight.

-

Food and Chemical Industries: The coil’s resistance to corrosion makes it suitable in environments where hygiene is paramount, such as food processing equipment and chemical containers. Additionally, its non-reactive nature serves to keep substances safe from contamination.

https://www.al-alloy.com/a/03mm-60mm-thickness-mill-finish-aluminium-coil.html