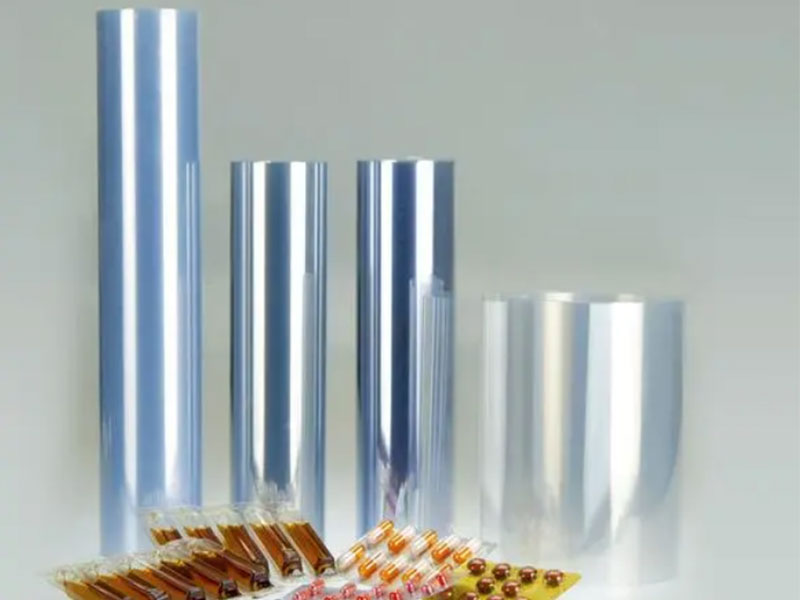

Aluminum foil packet blister capsules pharmaceutical packaging for pill

In the ever-evolving world of pharmaceutical packaging, aluminum foil packet blister capsules represent a significant innovation that enhances the medicine delivery systems we rely on. This unique packaging solution combines functionality with patient-centric design, making it a popular choice for pill manufacturers globally.

Understanding Aluminum Foil Packet Blister Capsules

Aluminum foil packet blister capsules are a comprehensive pharmaceutical packaging solution that offers individual compartments for pills while providing a robust barrier against factors detrimental to drug efficacy, such as moisture, oxygen, and light.

1. Enhanced Protection: One of the standout features of aluminum foil packaging is its exceptional barrier properties. Aluminum is impervious to light and moisture, effectively preventing pharmaceutical degradation, maintaining the potency of medications and extending their shelf life. This level of protection is crucial for sensitive formulations utilized within the industry, ensuring that the efficacy of each pill remains intact until the moment of consumption.

2. Convenient Dosing: Modern healthcare increasingly focuses on improving patient adherence to prescriptions. Aluminum foil packet blister capsules allow for convenient and accurate dosing. Each compartment is pre-measured, significantly reducing errors common with traditional bulk pill containers. This ensures that patients can easily access their medications, reducing the likelihood of incorrect dosages.

3. Tamper Evident Features: In safeguarding public health, the integrity of pharmaceutical products is paramount. Blister packs made from aluminum foil come with tamper-evident features that visibly indicate whether a pill has been accessed previously. This added layer of security fosters confidence in the products' safety, ultimately benefiting both patients and pharmaceutical companies.

Environmental Considerations

While aluminum is recyclable, there's greater emphasis on focusing on sustainability in packaging across many industries, including pharmaceuticals. Packaging developers are exploring ways to manufacture aluminum foil blister packs that reduce material thickness without compromising strength or quality. Allied with advancements in recycling processes, emissions may decrease, making a significant step tower toward greener packaging solutions within this sector.

Complementary Packaging Solutions

Aluminum foil packet blister capsules can complement other types of packaging. For instance, they can work effectively alongside outer cartons or drug label systems, allowing for increased protection while also providing vital information to the consumer. Drug manufacturers must assess these layered options to ascertain the values—essential in ideal drug therapy evaluations.