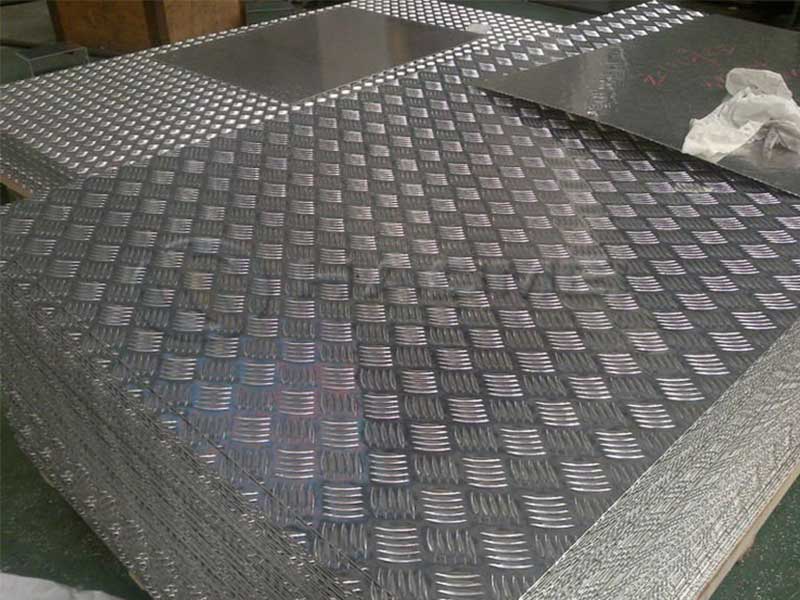

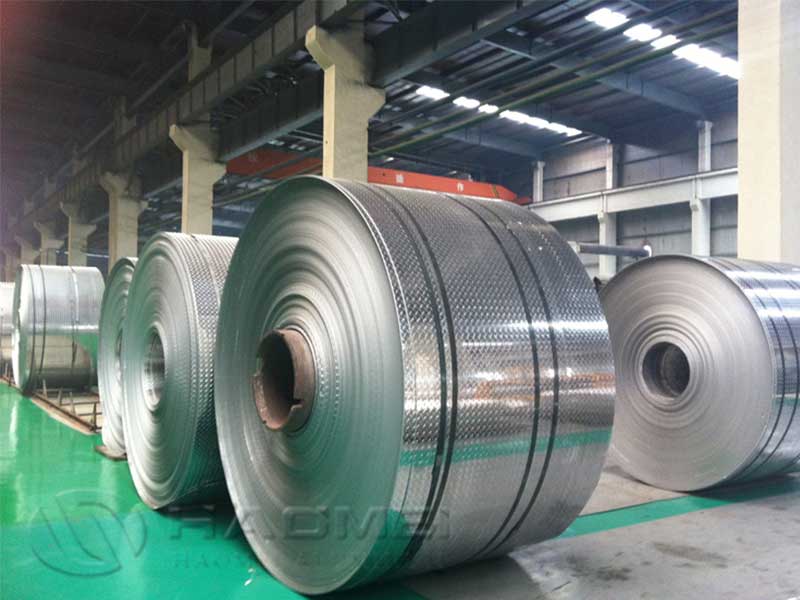

Patterned aluminium sheet

Patterned Aluminium Sheet: Crafting Strength and Style Beyond Ordinary Metal

In the realm of construction and design, materials are often chosen for their utility or looks—rarely both. Patterned aluminium sheets, however, break this mold with a unique blend of aesthetics, durability, and functionality, making them a top-tier choice in various industries. But what truly sets these sheets apart is their intricately embossed surface patterns, offering more than just visual appeal; they are engineered solutions born from a deep of how texture transforms metal performance.

The Distinctive Features of Patterned Aluminium Sheets

At first glance, a patterned aluminium sheet might appear simply decorative. Yet, its features speak volumes about thoughtful engineering:

-

Enhanced Grip and Safety: The embossed patterns aren’t just decorative. Raised textures such as diamond, checkered, or ripple patterns create gripping surfaces that reduce slipping risks, especially in flooring applications or staircases.

-

Increased Structural Rigidity: Unlike smooth sheets, patterned aluminium achieves increased stiffness without adding weight. The corrugated or dimpled designs distribute forces more evenly across the surface, immobilizing dents and improving load-bearing capacity without sacrificing flexibility.

-

Corrosion Resistance: Like standard aluminium, patterned sheets preserve inherent resistance to rust and corrosion. Their surface textures sometimes reduce the contact area for contaminants, thereby enhancing durability in harsh or wet environments.

-

Weight Efficiency: Maintaining aluminium's trademark lightweight quality, these patterned variants help architects and engineers optimize materials for projects requiring minimal structural load yet capable of enduring stress.

-

Aesthetic Versatility: Available in varied patterns and finishes—from brushed metallic shines to anodized colors—patterned aluminium becomes a material of choice not just for utility but also for stunning modern design lines.

Applications: Where Pattern Meets Purpose

The combination of practical texture and lightweight endurance expands the role of patterned aluminium sheets in multifaceted environments:

-

Architectural Facades and Cladding: Serving both as an exterior skin that protects buildings and elevates visual appeal, patterned aluminium sheets withstand environmental exposure while offering embossing that plays with light and shadow for dynamic aesthetics.

-

Transport Vehicles: From aviation flooring that prioritizes non-slip surfaces to truck bodies requiring sturdiness without excessive weight, patterned sheets marry performance with safety requirements.

-

Industrial Platforms and Walkways: Factories and refineries benefit from their high grip surfaces, preventing workplace accidents while avoiding the need for additional anti-slip modifications.

-

Interior Design Elements: Patterned aluminium ventures into interior use as feature walls, ceilings, decorative panels, or furniture accents—where industrial cool meets artistic craftsmanship.

-

Consumer Electronics and Appliances: Beyond heavy industrial roles, subtle patterned shells on electronic device casings or appliance surfaces add tactile interest and functional grip, enhancing user experience.

A Synergy of Design and Engineering

What’s truly fascinating about patterned aluminium sheets is their emergence as a product born of interdisciplinary innovation. Material scientists, design engineers, and artists collaborate to modulate how simple sheets of metal transcend conventional limitations—combining lightness, resilience, safety, and artistry.

By choosing patterned aluminium sheets, industries don’t just select a raw material; they adopt a layered solution addressing practical challenges while opening a door to innovative expressions. Whether it’s the secure footing underneath an airplane crew member or the vibrant facade that modernizes a corporate headquarters, this versatile material advances both form and function in unexpected harmony.