Aluminium checker plate

When stepping into a world dominated by modern materials, the aluminum checker plate stands out not merely for its rugged practicality, but for its striking design potential. As a natural blending of strength and aesthetics, the captivating texture of its pattern instantaneously captures attention, transforming traditional ideas of functionality into artistic applications. In this exploration, we’ll examine aluminum checker plate not only through the lens of its industrial utility but also from a designer's vantage point where every application becomes an opportunity for creativity.

The Symphony of Form and Function

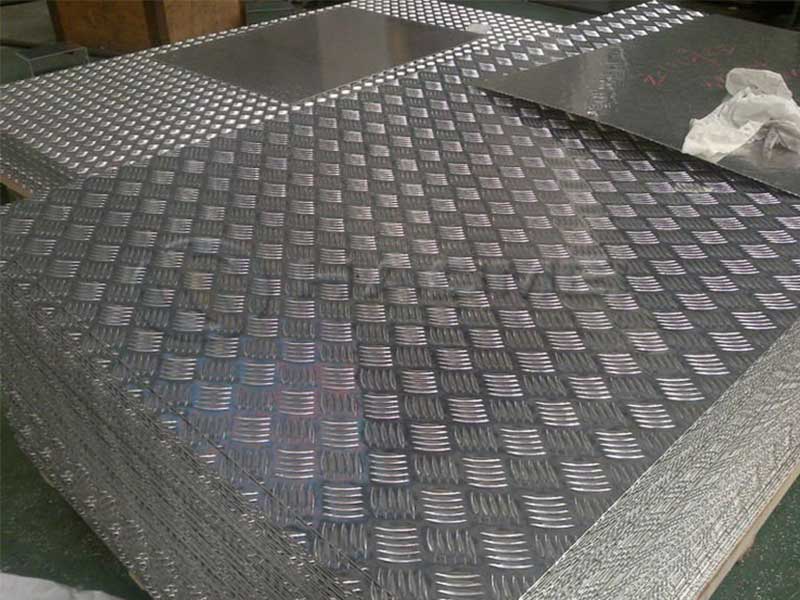

The distinctive diamond pattern that characterizes aluminum checker plate is more than a visual statement; it provides a clear functional benefit. The raised sections improve grip and traction, making it particularly valuable in environments where safety is a priority, such as stairways, walkways, and in vehicle floors. From an artist's perspective, these patterns can evoke dynamism and energy—driving home the notion that safety doesn’t have to be mundane or merely functional.

Working with aluminum checker plate daily reveals its unique strengths and weaknesses. The most common issue I see is related to surface damage during handling and fabrication. While the embossed pattern provides excellent grip, it also creates stress points prone to scratching and denting, especially during stamping, bending, or welding. This necessitates careful handling throughout the production process, from raw material storage to final product packaging. We've experimented with different protective coatings and handling techniques to mitigate this, finding that a combination of careful stacking with protective interleaving and the use of specialized tooling during fabrication yields the best results in minimizing surface flaws and maintaining consistent product quality.

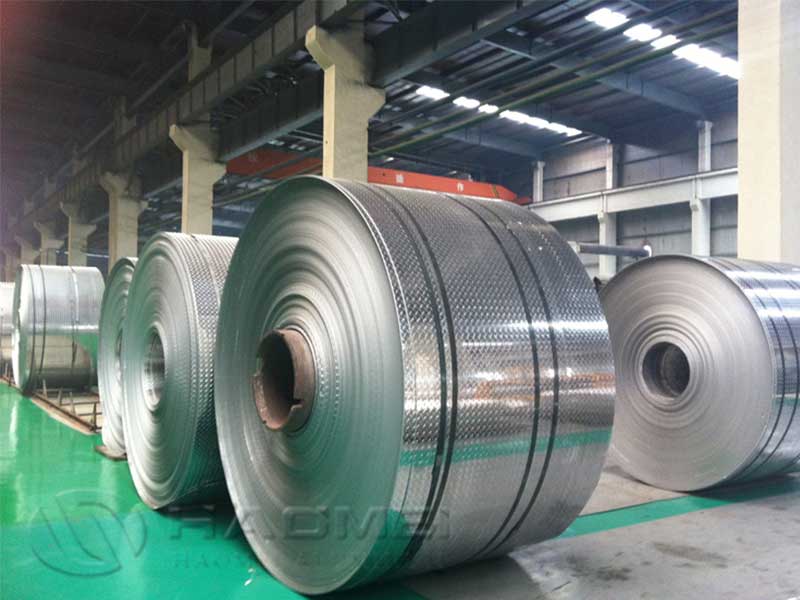

Beyond surface damage, another consideration is the alloy selection. Different alloys exhibit varying degrees of strength, formability, and corrosion resistance. For instance, 5052 alloy is favoured for its excellent corrosion resistance in marine environments, but its lower strength might not be suitable for applications demanding high load-bearing capacity. We've learned to tailor our alloy choices to the specific application, that a seemingly small difference in alloy composition can significantly impact the final product's longevity and performance. This demands a close collaboration with our clients to ensure they receive the optimal material for their intended use, maximizing both performance and cost-effectiveness.

Crafting Spaces with Texture

Imagine walking into an office where the elevator floor is polished aluminum checker plate. The light reflects off the silver surface, interplaying with the shadows created by its unique surface pattern. Designers often overlook flooring choices, but aluminum checker plate can redefine the concept of everyday materials used in workplace and retail designs.

Moreover, utilizing aluminum checker plate doesn't stop at flooring. Designers can wield this versatile material to craft resilient wall panels, art installations that engage viewers, or even bespoke furniture that transforms public spaces. The synergy of practicality with visual interest provides a methodical approach to interior design that is both thoughtful and contemporary.

Versatile Applications Across Industries

While the aesthetic value is certainly noteworthy, the aluminum checker plate excels across multiple industries for its practical properties. Its corrosion resistance makes it suitable for outdoor environments and maritime settings, ranging from platforms in shipbuilding to trailers used for transport. Each swath can tell a harrowing story of endurance, weathering the elements while maintaining its integrity and charm.

Automotive Inspirations

As someone invested in vehicular design, aluminum checker plates find a place in many automotive applications. With their light weight yet robust nature, they become favorable choices for cargo floors in trucks and delivery vehicles. However, it’s not just about utility; it’s about evoking an image—a backdrop of rugged reliability blended with a sleek profile. As automotive designers push towards agile, modern structures, aluminum checker plate becomes a logical and meritorious choice that satisfies both criteria.

Sustainable Performance

In an era where sustainability takes center stage, aluminum carries advantages beyond its functional attributes. It is a fully recyclable material, meaning the life cycle of aluminum checker plates can be revitalized rather than diminished through reuse and recycling processes. This resonates with a growing demographic seeking responsible choices in fabrication and design. Limiting waste and opting for sustainable materials opens intriguing dialogues about the designer’s role in briefing environmental impacts.