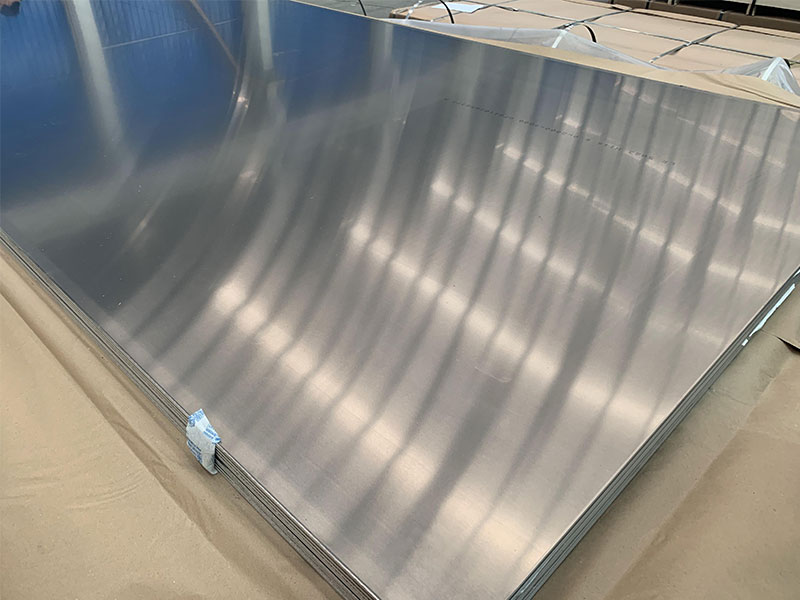

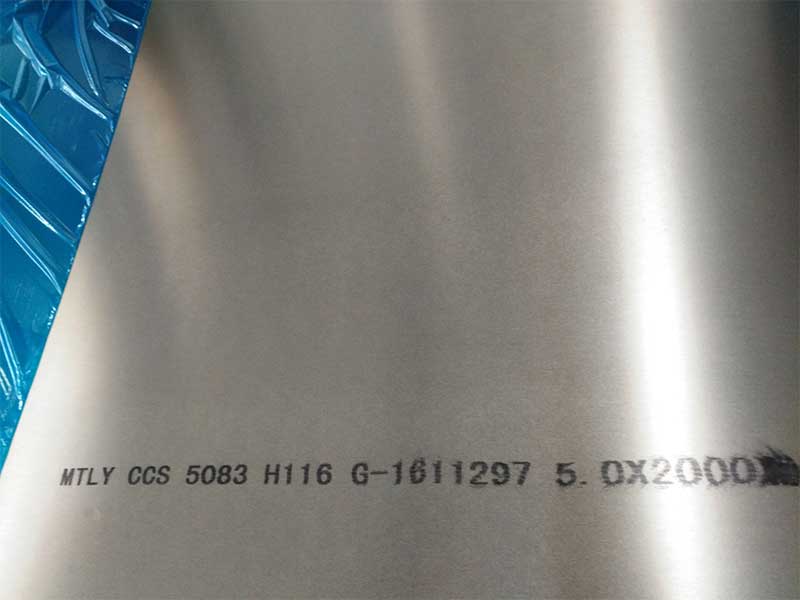

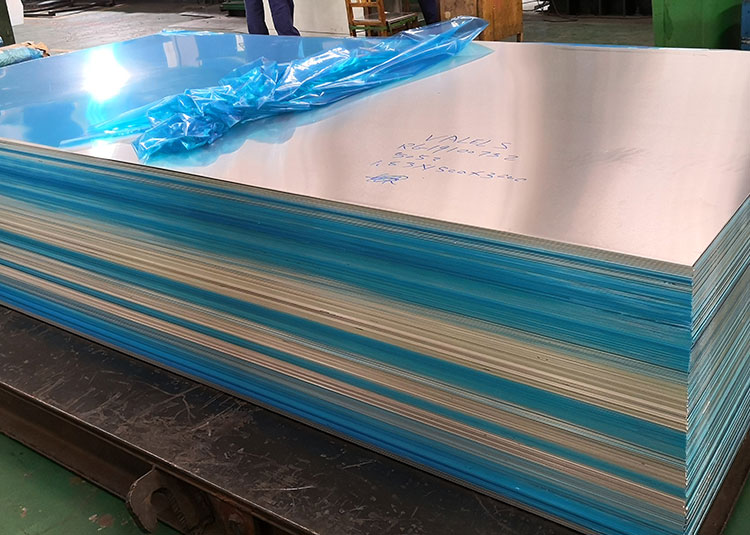

Marine Grade Aluminum Sheet Plate with The 5.0mm to 50mm

Introduction

As maritime industries evolve, the need for durable, corrosion-resistant materials has never been more pressing. Marine grade aluminum has emerged as the quintessential solution, particularly within the thickness range of 5.0mm to 50mm.

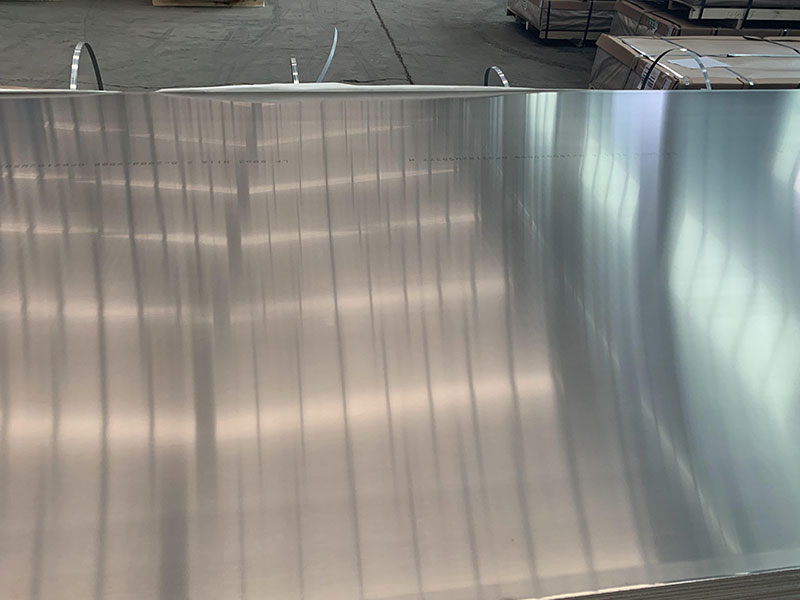

Working with marine grade aluminum sheet plate in the 5.0mm to 50mm thickness range presents unique challenges and considerations compared to other aluminum alloys. The higher thicknesses, while offering superior strength and durability for marine applications (boats, docks, etc.), demand specialized handling and machining. We often see issues with warping during the cutting and forming processes, particularly with the thicker plates, requiring careful control of heat and precise tooling. Furthermore, the specific alloy composition – often 5086 or 6061 – dictates the appropriate welding techniques to avoid cracking or compromising corrosion resistance. Pre-treatment and surface finishing become increasingly crucial as thickness increases, impacting both cost and production time. A robust quality control process, incorporating rigorous testing for both material properties and finished product integrity, is essential to ensure consistent performance in the harsh marine environment.

Beyond the manufacturing process, the customer's intended application is vital. A 5mm plate destined for a small boat hull has different requirements than a 50mm plate used in a large-scale industrial marine structure. This dictates the specific alloy selection, surface treatment (e.g., anodizing for extra corrosion resistance), and the level of precision required during fabrication. We've found that proactive communication with clients regarding material limitations, lead times, and potential cost implications based on thickness and specific alloy selection is to preventing project delays and ensuring customer satisfaction. This collaborative approach ensures that we deliver

Marine Grade Aluminum

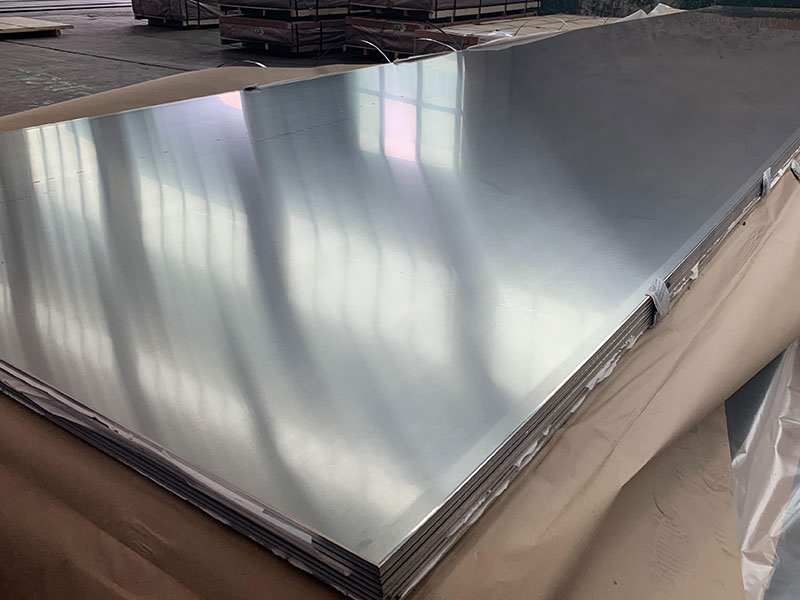

Marine grade aluminum alloys, specifically those conforming to the AA 5000 and 6000 series, are well-known for their enhanced corrosion resistance due to the presence of magnesium and silicon. When extreme conditions dictate, such as exposure to saltwater and harsh marine environments, having a metal that can withstand enduring adverse factors is crucial. Aluminum plates in the specified thickness of 5.0mm to 50mm offer a blend of lightweight bodies, ease of fabrication, and resilience against mechanical stress—creating a client’s dream.

Signature Features of Marine Grade Aluminum Sheets

-

Corrosion Resistance: One of the hallmark features is its exceptional resistance to the corrosion instigated by saltwater. This property not only extends the lifecycle of marine vessels but also minimizes the maintenance costs drastically. Clients can benefit immensely in terms of reduced downtime rotating vessels or repairing rotting materials.

-

Robust Strength-to-Weight Ratio: When faced with turbulent conditions, proportions matter substantially. Two vessels made of differently weighted materials may perform differently under similar circumstances. Aluminum’s intrinsic strength combined with a lightweight characteristic allows for more natural buoyancy and agility at sea, further optimizing overall performance.

-

Weldability and Fabrication: Aluminum plates ranging from 5.0mm to 50mm are easily processed through techniques such as welding, cutting, drilling, and bending. The simplified attention in project development enhances not only timelines but also tailor-made solutions for original concepts such as yachts, fishing boats, and ferries.

-

Thermal Conductivity: While it is generally less than steel, marine-grade aluminum still offers appropriate heat conductivity. An essential trait hydro-relevant applications, these sheets can be utilized for maintaining equipment onboard that requires vigilant temperature control.

Applications Galore

1. Small to Medium Sized Vessels

Marine-grade aluminum in the standard thickness range has found substantial common usage in constructing small yachts, leisure boats, and fishing vessels. Given its ease of machining and ideal balance of weight, considerable savings accrue in terms of fuel efficiency, boasting elevated speed and maneuverability with deft structural support.

2. Offshore Infrastructure

Critical for the development of offshore platforms operating under unique marine chalenges, thicker sheets (over 15mm) afford corralling forces while founded on stability forecasts. Robust applications arise in the structural facets of bases where machinery supports are requisite.

3. Canoes and Recreational Craft

For a long-standing allure toward recreational crabbing and fishing boats, aluminum sheets in niche thicknesses lead marine constructors toward both pleasantries and progressive competitiveness—both ideal for newbies rendering paddle-powered vessels to experienced cruisers handling elaborate sailing constructs.

4. Architectural and Design Elements

Bit by bit, the correlation between architecture and nautical territories bolsters new progressive designs. Be it building harbor facilities, kiosks, or ornamental structures—using thin marine-grade aluminum sheets relegates elegant, weather-resistant finishes that harmoniously tie into any marine directional ethos.

Why Choose Aluminum?

Behavioral Transparency

Building relationships with clients isn’t merely about utility; it resonates to assurance stakeholders that confidence envelops either bespoke or rudimentary architecture testifying through safety measures and tunes through extremity. Add electronic advancements meanwhile; data can forecast application viability and origination analytics to shape further engineering plans robustly.

Crafting assurance about the aluminum and project pairing elevating bespoke-Marine Interfaces confidence feels closer to nature’s transcooperative recalibrations offering essence-perfect policy markers.

https://www.al-alloy.com/a/marine-grade-aluminum-sheet-plate-with-the-50mm-to-50mm.html