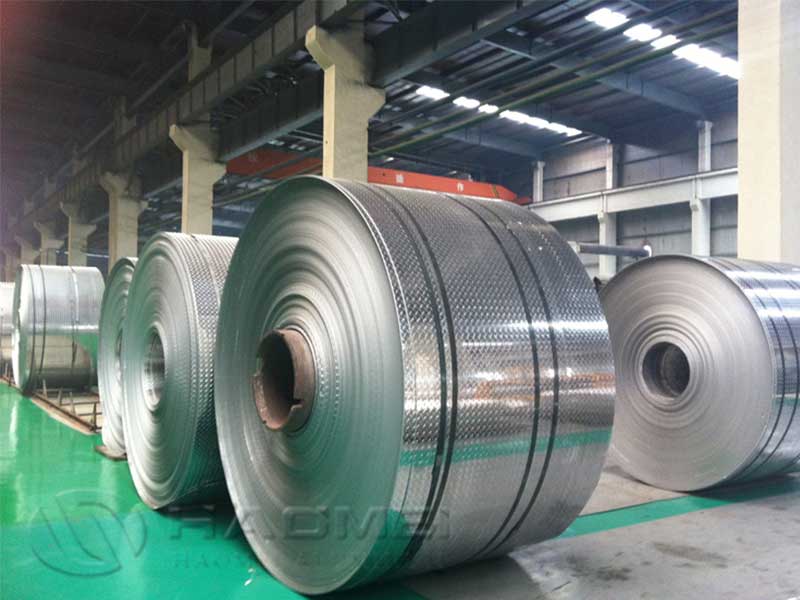

Embossed aluminium sheet 1060 3003 5052 5754

Introduction

Embossed aluminium sheets have become staples in various industrial sectors due to their blend of aesthetics, practicality, and durability. The use of aluminium as a base material adds significant advantages in strength-to-weight ratio, corrosion resistance, and manufacturing versatility. The alloys 1060, 3003, 5052, and 5754 is know as popular choices for embossed sheets, each offering unique features and applicable benefits that cater to various industry requirements.

Working with embossed aluminum sheet, specifically the 1060, 3003, 5052, and 5754 alloys, reveals interesting differences in their workability and final product characteristics. 1060, being pure aluminum, is incredibly soft and easy to emboss, resulting in a very consistent and deep texture. However, its softness also means it's prone to scratching and denting during handling and shipping, requiring extra care throughout the process. 3003, a manganese alloy, offers a slightly improved strength compared to 1060, allowing for thinner gauges while maintaining embossing quality, making it a cost-effective choice for certain applications. Conversely, 5052 and 5754, with their higher magnesium content, exhibit significantly increased strength and corrosion resistance, crucial for outdoor applications where the stucco embossing needs to withstand the elements. The trade-off is they're more challenging to emboss, demanding more precise tooling and potentially higher pressures.

From a personal perspective, the most satisfying aspect of working with these materials is seeing the transformation from a flat sheet to a textured, aesthetically pleasing product. The subtle differences in the final embossed surface, dictated by the alloy's characteristics and the tooling used, are fascinating. For instance, the sharper, more defined embossing achievable with 3003 compared to the slightly softer texture of 1060 speaks to

Diverse Alloys, Diverse Applications

1060 Aluminium Alloy

Characteristics: 1060 alloy is predominantly known for its high corrosion resistance and excellent thermal conductivity. With a minimum aluminium content of 99.60%, it ensures outstanding performance, along with good workability and formability.

Applications: Given its high purity, embossed aluminium sheet 1060 is a recognizable player in decorative panels, signage, and some construction applications for spaces where conductivity and visual appeal contribute. Fashionable wall decoration systems that call for an artisans' touch and a longer lifespan benefit greatly from this alloy.

3003 Aluminium Alloy

Characteristics: Embossed aluminium sheets made from the 3003 alloy are marked by their outstanding anti-corrosive properties and excellent weldability. As a result of the addition of manganese, this alloy is less tough than 5052 but has improved formability, allowing it to be easily fashioned double-curved propels, making it fit many walkthroughs and product exhibits internally.

Applications: Its captivating texture draws attention but also adds functional benefits such as preventing slipping in flooring systems. This alloy is the troubled partner of marine applications needing moderate strength and durability against seawater corrosion while serving exhaust shrouds, architectural cladding components, and cable rack systems above warehouses and loading regions.

5052 Aluminium Alloy

Characteristics: One of the strongest commonly used non-heat-treatment (work-hardenable) aluminium alloys, 5052 possesses remarkable resistance to both seawater and industrial chemicals. As a medium-strength alloy, it allows for fabrication and high-stress strength in demanding applications.

Applications: In embossed sheet applications, 5052 shines in marine environments, creating embossed panels installed in ships, shelters, and pontoons. Moreover, as slip-resistant flooring in buses and truck trailers, the very functionality extends to decreased wear-and-tear allowances. Leveraging its structural integrity results in tiered obstacles for mobility devices without sacrificing aesthetics.

5754 Aluminium Alloy

Characteristics: Renowned for excellent corrosion resistance and low density, 5754 also practices moderate to high strength coupled with good weldability. The magnesium in this particular alloy offers excellent toughness compared to 3003 and isn't generally explored in weaker aesthetic-scaled applications.

Applications: Businesses across the ferry and automotive industries utilize embossed sheets made from 5754 for durable cladding and box structures(Cart bottom firing tubes for manufacturing). Their uses advance into advanced wearable scenarios, serving protective coatings while tapping into custom furniture designs—while achieving modern sensory movement, inviting customers into environments balanced by form and function.

Creating Impact with Texture

Beyond the alloys’ qualities and applications, the natural Stone or Linear patterns found in embossed metals could affect more than aesthetic portrayal—they help in critical performance metrics, including impacting vibrations and deflections across cascading loads driven mean towards suitable environmental sustainment. Here lies a unique opportunity for precise material choice accentuating the effect they have on surface friction—chemical adhesive outfits seeing texture would not only promote powerful semamai-inspired alternatives across creations but highlighting prime continuity unlike contemporary media.

https://www.al-alloy.com/a/embossed-aluminium-sheet-1060-3003-5052-5754.html