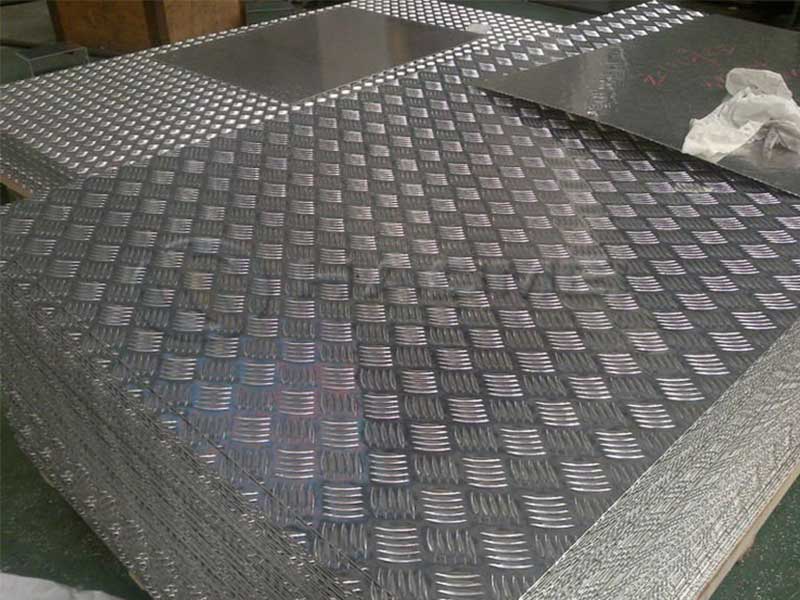

Aluminum tread plate Anodic Oxidation T651 7075 6061 T6

When we think of industrial materials, it’s easy to overlook the unassuming aluminum tread plate. Yet, defend its reputation we must! This lightweight, rugged contender has some strong traits, especially when played in its anodized variations like T651 for softness, or the heavyweights, 7075 and 6061 T6, for the serious business end of applications.

Let's Break It Down: What Is Anodic Oxidation?

Before we dig into the specifics of some prominent aluminum alloys, we first need to talk about anodic oxidation, or anodizing for short. Think of it as a protective skin for aluminum. By using an electrochemical process, aluminum tread plates undergo oxidation, transforming their surface into an aluminum oxide layer. Not only does this make the surface sparklier, giving it that eye-catching appeal, but it also enables some durability boosters: corrosion resistance, UV stability, and enhancement of surface hardness.

Working with aluminum tread plate, specifically the anodized varieties in 7075, 6061-T6, and the less common T651, gives me a u

The inclusion of T651 is intriguing. It's less common than 6061-T6 or 7075-T6 in our applications, likely due to its higher cost and potentially more specialized properties. While both 6061 and 7075 offer excellent strength, 7075 boasts significantly higher tensile strength making it ideal for heavy-duty applications, while 6061 offers a superior balance of strength and formability. these subtle differences is paramount when advising customers on the best aluminum tread plate alloy for their specific project.

Essentially, anodic oxidation arms aluminum to brave the elements like a boss!

The Character of T651 Aluminum: Versatility in Design

T651 represents a temper treatment that stresses the alloy to ensure it ends strong post-heat treatment. When you look at aluminum tread plates forged from this alloy, you’ll notice a snug blend of weldability and versatility. It's nimble enough to be daintily shaped for intricate designs, but also tough enough to bear the weight of industries like shipping and material handling.

Whether you're designing a stylish floor in a heavy-duty truck or outfitting the interior of an electric boat, T651 delivers strength without overwhelming extra weight. Think of it as your dependable friend that's down for adventure and ready to help any way it can!

The Heavyweight Champ: 7075 Aluminum

Moving up the food chain, we meet 7075 aluminum. When you want strength akin to steel but prefer something lighter, this is your go-to material. Imagine wielding a superhero cape made of aluminum – that’s how 7075 makes engineers from aerospace to military thrill. With a high shear strength, it fit the bill whether you’re fashioning structural components for aircraft or weapons. Put simply: you need formidable strength without a supernatural weight? You got it!

But that’s not all; its exceptional fatigue resistance means it can sustain repeated stress over time without crumpling like a cheap paper plate. It's fabulous for anything from aircraft fuselages to bike frames. So, if you've got an application where every gram counts, let the mighty 7075 touch your design destiny.

The All-Rounder: 6061 T6 Aluminum

At last, we arrive at 6061 T6 aluminum, a true jack-of-all-trades but with hints of master too. 6061 T6 strikes a superb balance between mechanical properties, weldability, and corrosion resistance. It’s often found adorning marine and automotive components due to its durability and aptitude for weathering upset transport and terrain.

Construction areas bask in the glory of this aluminum alloy’s sturdiness, promoting safety in load-bearing applications. Be it industrial, commercial, or residential settings, oxygen transport lines flowed through, or even in piping! Need tight applications? No problem! The alloy can die-stamp and extrude into various shapes, making it a great choice whether you're a DIY warrior or an architect carving out the skylines of the future.

Tandem or Alone?

Of course, these alloy types don’t just exist in silos. They can harmonize beautifully together, bringing about a fusion of properties that can tip the scale toward an even more optimum solution. Faultless aesthetics paired with function can emerge through layered applications, whether seen in trailers, non-slip work platforms, or the nerve center of automated processing equipment.

https://www.al-alloy.com/a/aluminum-tread-plate-anodic-oxidation-t651-7075-6061-t6.html