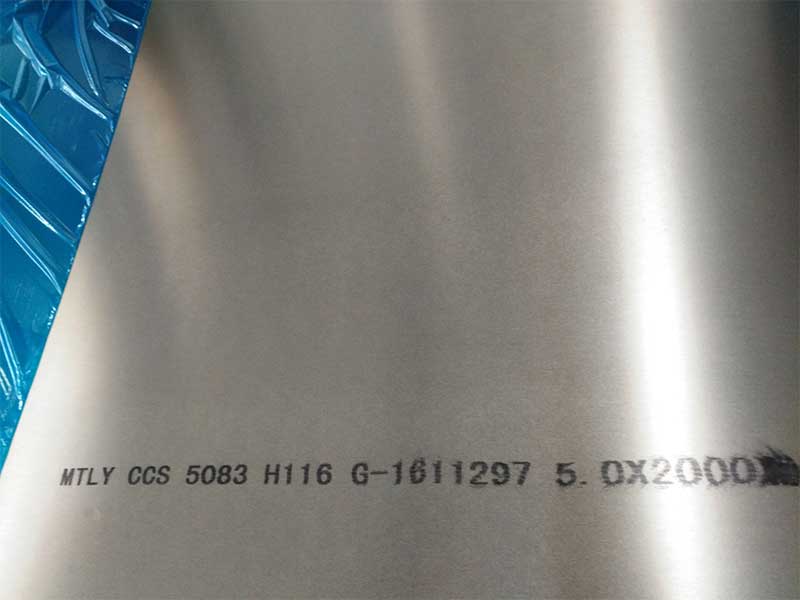

0.4mm 5083 Marine Grade Aluminum Sheet

When it comes to selecting materials for marine applications, the choice is critical; longevity, strength, and resistance to harsh environments are fundamental prerequisites. The 0.4mm 5083 marine grade aluminum sheet rises to the occasion as a reliable ally for maritime engineers, boat builders, and hobbyists alike.

The Merits of 5083 Aluminum: Beyond the Basics

The 5083 aluminum alloy belongs to a group of materials known for their superior resistance to corrosion, particularly in seawater. However, the allure of 5083 goes beyond its robust protective skin. At a mere 0.4mm thick, this aluminum sheet proves that resilience does not have to come with unnecessary bulk.

Working with 0.4mm 5083 marine grade aluminum sheet presents unique challenges compared to thicker gauges. Its thinness makes it incredibly susceptible to scratching, denting, and warping during handling, fabrication, and even shipping. We've seen significant losses due to damage incurred during the stacking and palletizing process, necessitating careful attention to protective interleaving and secure packaging. Furthermore, the inherent softness of 5083 alloy, even in its work-hardened state, requires specialized tooling and techniques for processes like punching, bending, and even simple shearing to avoid tearing or excessive deformation. Precise adjustments to press parameters and tooling geometry are crucial to achieving consistent and defect-free parts.

The marine grade designation highlights another critical aspect: corrosion resistance. While superior to many other aluminum alloys in this regard, 0.4mm thickness offers a smaller margin of error when it comes to surface imperfections or improper cleaning. Tiny scratches that might be insignificant in thicker sheets can become significant sites for crevice corrosion over time, especially in the harsh marine environment it's intended for. Therefore, meticulous surface preparation prior to any further processing – including thorough cleaning and potentially passivation – is paramount to ensuring long-term performance and adherence to the demanding quality standards of marine applications.

Traditionally, one might assume that choosing a thinner material like the 0.4mm 5083 sheet would compromise its structural adequacy. However, when you examine the balance between weight and strength, you discover a material that excels in scenarios where performance trumps mass. Especially in boat building, lighter materials translate to improved fuel efficiency and handling, offering significant advantages during operation.

Engineering Marvel: Cold Formability and Workability

One of the standout characteristics of the 5083 marine grade sheet is its enhanced cold formability. In more practical terms, this means it’s easier to shape and form, allowing engineers and fabricators to create consistent, precision-crafted components without sacrificing strength. For skyscraping hulls or intricate designs in yacht construction, 0.4mm 5083 can be molded into every curve and mold a designer envisions.

This flexibility opens new gates in design innovation, ensuring structural integrity while maintaining a lightweight, sleek look that is also aesthetically pleasing. It’s about more than raw abilities; it’s about combining craftsmanship and material excellence.

Corrosion Resistance: A Necessity in Marine Environments

Let's face it: the marine environment is one of the harshest vegetation on the planet. The unforgiving salt, humidity, and numerous other corrosive agents scour most other materials. The 5083 alloy excels in this grim setting with its solid mechanical properties and remarkable capacity to withstand the corrosive effects of saltwater.

When concerned with structural longevity, some marine applications delay inevitable failures tied to corrosion by utilizing this marine alloy. Thin sheets like the 0.4mm option are specifically designed not only to stand against chlorides but to outperform many other alloys, giving boat owners peace of mind and cost-effective maintenance solutions over pale substitutes.

Eco-Friendly Production: A Sustainable Choice

In today’s landscape, eco-consciousness permeates across sectors, and the marine industry is no exception. Recognizing its role in responsible manufacturing can elevate the perception of aluminum itself. Specifically, marine-grade aluminum sheets like the 5083 are often produced with a high percentage of recycled content—further boosted by their recyclability at the end of their usable life.

Opting for this alloy reflects a commitment to stewardship of the environment while assuring functionality. With boat builders harmonizing durability with sustainability, making sophisticated choices for a greener planet no longer feels like a—in many ways it isn't.

https://www.al-alloy.com/a/04mm-5083-marine-grade-aluminum-sheet.html