Aluminum sheet rolls 0.2mm

Aluminum sheet rolls have paved the way for innovations across multiple industries, and the 0.2mm thickness is particularly notable for its unique blend of flexibility, strength, and durability.

Technical Specifications

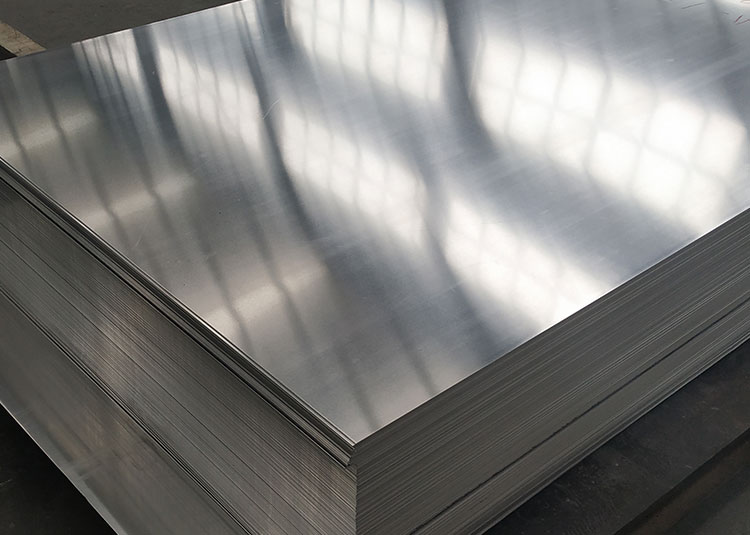

Before its practical applications, it’s important to better understand aluminum sheet rolls of 0.2mm. Typically made from high-quality alloyed aluminum, often from the 1000 or 3000 series, this gauge possesses excellent tensile strength while maintaining a relatively light weight.

Working with 0.2mm aluminum sheet rolls is a constant balancing act. It's incredibly thin, almost like heavy-duty foil, demanding meticulous care at every stage of production. A tiny snag on the rollers, a slight temperature fluctuation during annealing, or even static cling can ruin an entire roll. We're constantly tweaking parameters – tension, speed, lubrication – to maintain consistent gauge and surface finish. The slightest deviation can impact downstream processes, leading to rejects in the stamping or forming stages where this material is typically used. It's a testament to the precision engineering of our machinery that we can even produce it at this thinness consistently, and a source of quiet pride when a perfectly smooth roll comes off the line.

Beyond the technical challenges, I find this material fascinating. Its applications are incredibly diverse, from intricate electronic components to delicate architectural features. Knowing that the incredibly lightweight and pliable material I help to create contributes to such a broad spectrum of products is rewarding. The sheer amount of surface area contained within a single roll is striking; we’re essentially dealing with a huge, continuous, intensely thin sheet of metal, carefully curated and prepared for its final transformation into something larger than just a roll of aluminum. The responsibility of maintaining quality feels significant considering the often unseen role it plays in so many end products.

The typical traits of a 0.2mm aluminum sheet rolls include:

- Thickness: 0.2mm (arising the need for particular handling and processing skills).

- Width: Customizable widths, often spanning between 100mm and 1500mm.

- Finish: Available in both standard and various decorative finishes (e.g., brushed, mirror-polished).

- Corrosion Resistance: Outstanding resistance to corrosive environments, translating into extended longevity.

- Thermal Conductivity: Notably efficient thermal and electrical conductivity, adding to its versatility.

Functions and Their Applications

With these remarkable specifications, 0.2mm aluminum sheet rolls find their way into diverse sectors, each benefiting from the unique properties the material offers.

1. Consumer Electronics

In the consumer electronics industry, 0.2mm aluminum sheet rolls are prevalent in the fabrication of ultra-sleek housings for gadgets such as laptops, smartphones, and tablets. The thin profile enables companies to design for aesthetics without compromising structural integrity. Thanks to its favorable properties, this aluminum sheet is often used for components including heat sinks and backing plates, which help in thermal regulation.

2. Automotive Industry

The push for lightweight materials to improve fuel efficiency makes 0.2mm aluminum sheet rolls advantageous in automotive applications. It is commonly used in panel production, from sleek automotive body parts to bracing and insulation within the vehicle. Here, the formidable corrosion resistance proves helpful, especially when components are exposed to varying climatic conditions.

3. Architectural Elements

Architecturally, the 0.2mm aluminum sheet is widely used in building facades, roofing, and interior decoration. The decorative coatings available can mimic textures like natural wood or stone while whittling down the weight of materials used in construction. Its resistance to rust makes it perfect for cladding on buildings near coastlines, where exposure to moisture complicates maintenance.

4. Food Processing

In the food industry, aluminum's inert properties and excellent degree of machinability underpin the use of 0.2mm aluminum sheet rolls in manufacturing diverse food packaging solutions. Lightweight aluminum cases shield products effectively, making the transportation and storage more feasible and economical.

5. HVAC Units

Additionally, the versatility of 0.2mm aluminum sheet rolls extends to heating, ventilation, and air conditioning (HVAC) units. In these systems, components made from aluminum aid in improved airflow while minimizing the burden on routine systems placements without sacrificing durability.