Aluminum sheet 0.2mm Thickness 1050 1060 1100 Thin

Aluminum sheets have made their mark in numerous industries, standing out for their lightweight, durability, and recyclability. One specification that frequently garners interest is the aluminum sheet with 0.2mm thickness, particularly in the widely recognized heat-treated grades of 1050, 1060, and 1100. These grades are more than mere numerical identifiers; they each reveal distinct properties that lend themselves to a myriad of practical functions and innovative applications.

The Characteristics of 1050, 1060, and 1100 Aluminum Sheets

To appreciate the functionality of aluminum sheets at 0.2mm, it helps to understand the specific properties of these three grades.

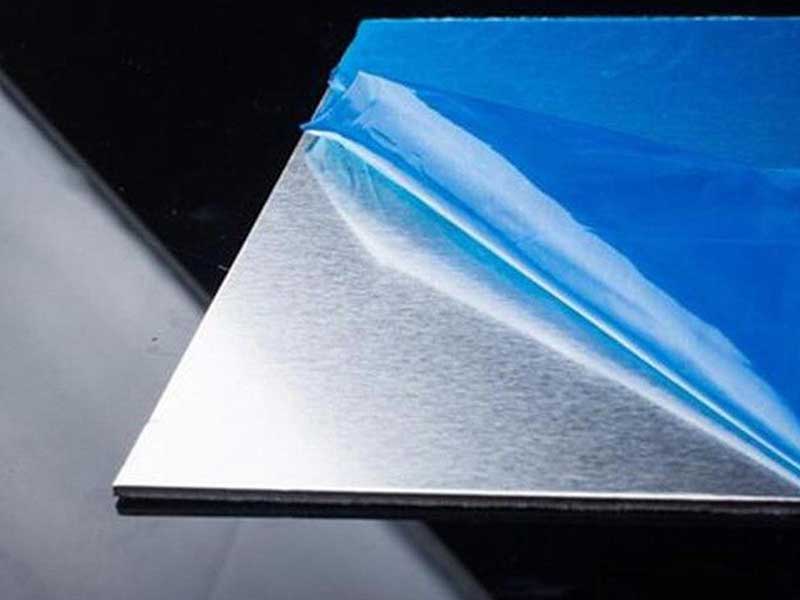

Working with 0.2mm thick aluminum sheets in 1050, 1060, and 1100 alloys presents unique challenges. Their extreme thinness makes them incredibly susceptible to scratching, denting, and warping during handling and processing. Even seemingly minor variations in humidity or temperature can cause significant dimensional changes, demanding strict environmental control throughout the production line. We've found that specialized tooling and techniques are essential – using softer rollers during rolling operations, implementing gentler handling procedures with specialized gloves and vacuum lifters, and carefully controlling the stacking and storage to prevent even minor stresses from accumulating. Careful selection of lubricants and cleaning agents is crucial to avoid surface damage, and we often see a higher rate of rejects due to these sensitivities compared to thicker gauge aluminum.

The extremely low yield strength of these alloys, particularly 1050, also requires careful consideration during downstream processes like stamping, forming, and printing. We've had success incorporating specialized dies and reducing press tonnage to minimize the risk of tearing or cracking. Furthermore, optimizing the annealing process is vital to achieve the desired level of softness and formability without compromising the sheet's integrity. Consistent quality control, involving regular thickness checks and surface inspections throughout the production process, is paramount to minimize waste and ensure that the final product meets stringent customer specifications. the nuances of handling and processing these ultra-thin aluminum sheets has been to our team’s efficiency and

-

1050 Aluminum is best known for an astonishing degree of ductility and high corrosion resistance. The entwinement of purity and workability make it a choice material for applications necessitating excellent electrical conductivity.

-

1060 Aluminum, while reminiscent of 1050, has slight variations in its properties, predominantly possessing superior conductivity due to a maximum 0.2% iron content. Thus, it's often preferred in situations where electrical performance can't be compromised.

-

1100 Aluminum boasts increased strength and retains many excellent conductivity characteristics, positioning it as a versatile option suitable for applications requiring a bit more toughness and wear resistance without thickening up the materials.

Functions Driven by Thickness

A thickness of just 0.2mm presents several strategic advantages:

1. Weight Efficiency

In aerospace, automotive, and construction industries, reducing weight while maintaining structural integrity is crucial. Aluminum sheets with a thin 0.2mm thickness facilitate innovative designs and challenge traditional notions of material application. By incorporating these sheets, manufacturers create lightweight frames and enclosures, resulting in considerable savings in transportation and energy consumption.

2. Enhanced Thermal Conductivity

In the realm of heat transfer applications, the conductive properties of thin aluminum sheets become vital. They allow for superior thermal dissipation compared to thicker conventional panels. This property sees widespread application in electronics—particularly in heat sinks, where managing temperature efficiency translates to improved product performance and longevity.

3. Customization in Crafting

Aluminum sheets of this thinness are not constrained to industrial applications—artists, craftsmen, and designers leverage them for varied applications. The distinctive technical properties, such as malleability and resilience, allow for fine crafting of a diverse range of aesthetic products, ensuring they can adhere well to curves without sacrificing strength or form.

Diverse Applications in Various Industries

The versatile configurations of 0.2mm aluminum sheets in 1050, 1060, and 1100 grades transcend the standard. Here’s a glance at pioneering ways these sheets are implemented:

-

Transport: Within the automotive sectors, designing components like trunks or paneling becomes intuitive with thin aluminum sheets offering durability while subtracting unnecessary weight.

-

Food and Chemical Processing: Grade 1100 is often utilized in manufacturing finely processed equipment due to its excellent resistance to corrosion from various elements.

-

Packaging Innovations: The flexibility of these sheets has led to innovations in food and pharmaceutical packaging, offering protective and convenient configurations that ensure product safety without compromising the boundary of rigidity.

https://www.al-alloy.com/a/aluminum-sheet-02mm-thickness-1050-1060-1100-thin.html