Aluminum mirror finish sheet

Aluminum in itself is a remarkable metal known for its lightweight nature, corrosion resistance, and exceptional formability. But when you take it a step further and apply a reflective finish, you create mirror aluminum sheets — a material with applications far beyond mere aesthetics.

Mirror Aluminum Sheets

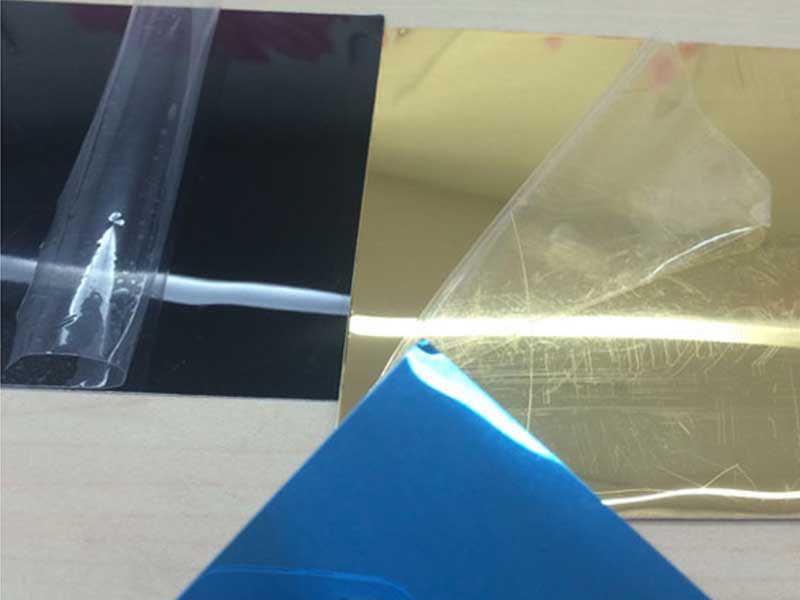

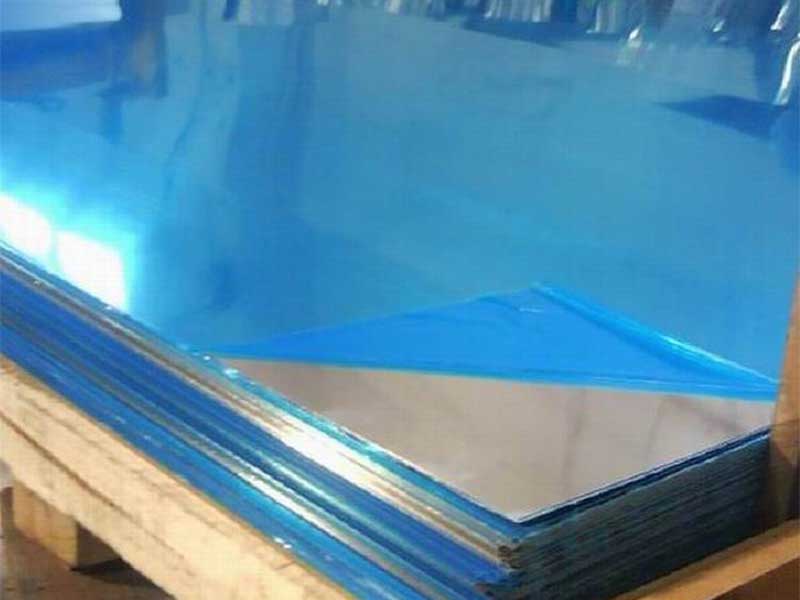

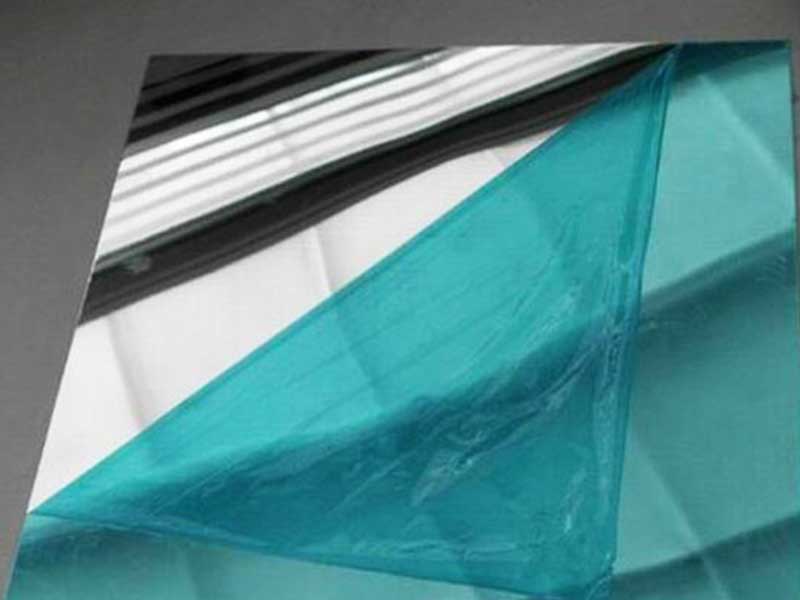

Mirror aluminum sheets are specifically engineered through a sophisticated manufacturing process that involves anodization or polishing techniques. After the aluminum is shaped into sheets, a reflective layer is created through polishing — resulting in surfaces that exhibit high reflectivity, comparable to glass mirrors both in quality and utility.

Typically, E230 or ℃3003 alloys are utilized for mirror-finish aluminum sheets due to their exceptional workability and mechanical properties. With thicknesses ranging typically from 0.025mm to 3mm, these sheets strike a balance between reflectiveness and durability.

Functional Attributes

-

High Reflectivity: One of the most notable features of mirror aluminum sheets is their reflective capability, some observe as high as 90% reflectivity. This attribute makes them perfect for lighting components and decorative purposes.

-

Corrosion Resistance: Unlike traditional mirrors made from glass, aluminum doesn't shatter and excels in environments with moisture. The anodized surface boosts its resistance to corrosion, ensuring longer-lasting applications — an excellent choice for outdoor usage, including signage and architectural elements.

-

Lightweight: Aluminum’s lightweight nature allows these mirror sheets to be transported and installed with relative ease, facilitating creative freedom from residential spaces to large-scale installations.

Applications Across Industries

1. Architectural Design

In modern architecture, mirror aluminum sheets serve both functional and structural purposes. They are frequently utilized in exterior cladding applications, aesthetics, sunshades, and creative installations, embodying a balance between visual appeal and practical performance.

2. Automotive Sector

Mirror aluminum sheets are beneficial in applications gearing toward lightweight design for vehicles. These sheets can achieve high reflectivity while adding minimal weight, thereby improving fuel efficiency. Frequently incorporated in headlamp reflectors, these materials dramatically increase visibility.

3. Interior Design

Utilizing mirror aluminum sheets in interior design trends enhances spaces through the effects of light and reflection. Popular applications include wall panels, furniture accents, and ceiling installations that cultivate an ambiance of modernity and charm. Designers adore using these sheets for creating eye-catching architectural features and sound-absorbing wall panels.

4. Solar Energy

Reflectivity takes center stage in solar applications. Mirror aluminum is employed in certain solar cookers and reflective panels to optimize sunlight absorption, effectively directing it where needed. This practical design artfully blends function with sustainability.

5. Display and Lighting

Computers and electronics commonly use mirror aluminum sheets in reflective surfaces on LED displays and fixtures. These sheets effectively bounce illuminating light, enhancing brightness, while maintaining an unobtrusive aesthetic appeal.

https://www.al-alloy.com/a/aluminum-mirror-finish-sheet.html