High Reflective Mirror 1060 Aluminum Coil

If you've ever looked in a mirror and marveled at the crisp reflects of your stylish attire or unruly morning hair, a considerable scientific process sits behind that literal mirror image. Enter the High Reflective Mirror 1060 Aluminum Coil—a surprisingly versatile hero in the realm of industrial applications that goes well beyond your vanity.

The Core of 1060 Aluminum

First, l

The 1060 aluminum alloy is a popular choice for high-reflective mirror applications due to its excellent surface finish capability and relatively high purity, leading to superior reflectivity compared to other, more alloyed aluminum grades. However, achieving truly "high-reflective" status with 1060 coil requires meticulous control throughout the production process. We've found that even minor inconsistencies in rolling parameters, annealing temperatures, and surface finishing techniques can significantly impact final reflectivity. Surface imperfections, whether from rolling defects or inadequate cleaning, act as scattering centers, reducing the overall specular reflection. Therefore, consistent monitoring and fine-tuning of these parameters are crucial, and often involve advanced quality control measures like laser surface profilometry and spectral reflectance measurements.

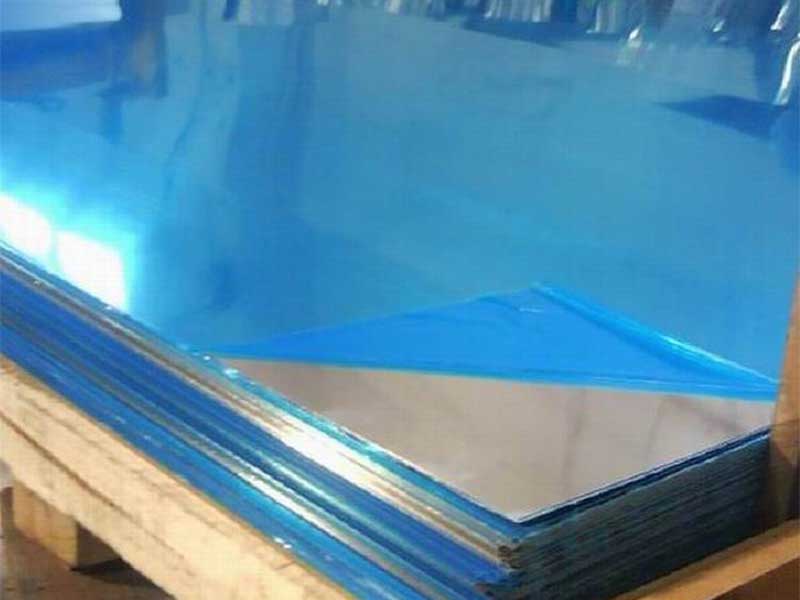

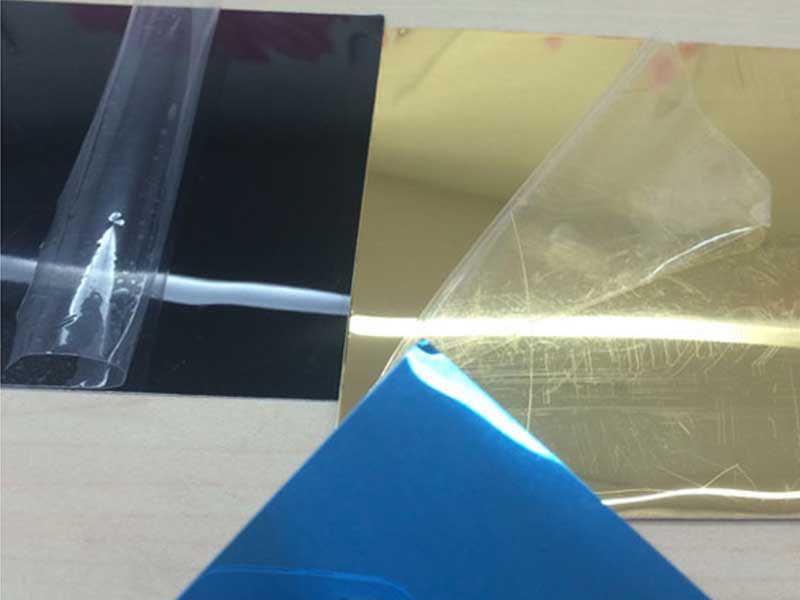

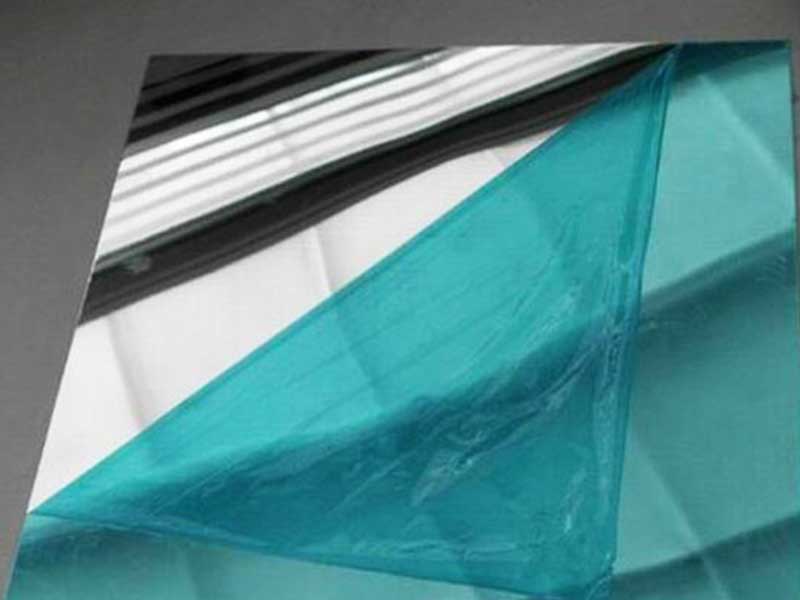

Beyond the production process, the ultimate reflectivity of the 1060 aluminum coil is also affected by environmental factors. Exposure to air leads to the formation of a thin oxide layer, which degrades reflectivity over time. We've seen cases where improperly stored coils show a noticeable decrease in reflectivity after just a few months. Protective coatings, such as anodizing or specialized polymer films, are often necessary to maintain the high reflectivity demanded by our customers, especially in applications requiring long-term performance. Therefore, the interplay between material properties, manufacturing precision, and post-production protection is essential for supplying truly high-quality, high-reflective 1060 aluminum coil.

Reflective Functions: Shimmering Technology

The reason why High Reflective Mirror 1060 Aluminum Coils are all the rage boils down to one defining feature: superior reflectivity. It reflects up to 90% of white light, making it ideal for countless applications including but not limited to lighting, electronics, and even solar energy solutions. For all those aspiring lighting designers out there, think of this material as your magical wand that makes your projects visually stunning while contributing to energy efficiency! It’s the eco-friendly glam your projects crave.

Forging New Frontiers: Where to Spot It

This aluminum marvel isn’t just one of those behind-the-scenes types; it makes grand appearances across a variety of industries. Here are a few applications that might just spark a little inspiration:

-

Architectural Facades: High Reflective Mirror 1060 Aluminum Coil is often utilized in the construction world as component panels, which not only enhance aesthetic qualities but also comply with sustainability targets. Who doesn’t want eco-chic buildings that double as solar power harnessers, right?

-

Automotive Industry: For those who adore underground car shows, you may witness these coils being utilized in reflecting headlights or as inserts within LED tech in your beloved vehicles. Trust me, your next spotlight catch is 50% gleam, 50% High Reflective Mirror goodness!

-

Solar Energy Sector: Ever heard of solar thermal systems? Prepare to catch some rays for days! This reflective aluminum coil looks out for us at a macro level too, by boosting the efficiency of solar collectors. It absorbs sunlight and sends it down to power up your homes brilliantly.

-

Signage and Displays: Want your signage to pop? Using the High Reflective Mirror can turn pedestrian notices into striking installations depending on ambient lighting. I can assure you, it turns ‘meh’ looks into eye-catching ‘wow’ moments.

The Production Process: A Shiny Work of Art

Creating these reflective coils involves a well-coordinated dance of metallurgy and artistry. The process starts with melting down aluminum and casting it into sheets. These sheets are then rolled to make the coils thinner and more adaptable. Coming later, a myriad of polishing and anodizing processes take place—remember, more shine equates to more reflectivity. It’s like turning the drab into fab overnight!

https://www.al-alloy.com/a/high-reflective-mirror-1060-aluminum-coil.html