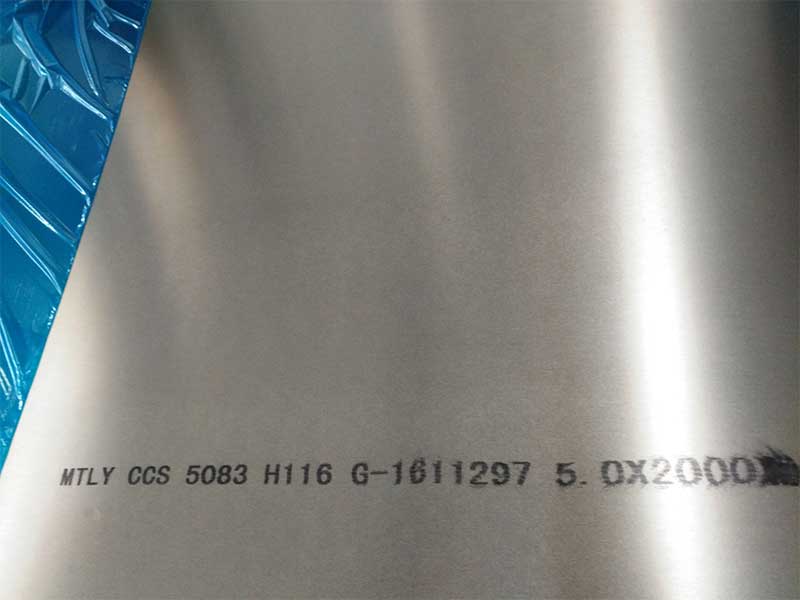

5083 Tanker with Aluminum Sheet

When it comes to tankers and other massive vessels designed for transporting liquids, the choice of materials significantly affects performance, durability, and safety.

What Sets 5083 Aluminum Alloy Apart?

The designation “5083” refers to an aluminum alloy that belongs to the 5000 series, predominantly composed of aluminum (4.0-4.9% magnesium) and a small percentage of manganese. Here are some distinctive features that set it apart:

Working with 5083 aluminum alloy in tanker construction is a constant balancing act. We know its exceptional strength-to-weight ratio is crucial for fuel efficiency and payload capacity, making it a premium choice for tanker manufacturers. However, the formability during the sheet production process can be tricky. Getting the precise gauge and surface finish required for seamless welding and subsequent tank integrity is a daily challenge, particularly when dealing with larger sheet dimensions. A tiny imperfection in the rolling or annealing stages can propagate into a major issue down the line, impacting the overall structural strength of the tanker. We meticulously monitor every stage, from raw material analysis to the final inspection of the finished sheets, to ensure we meet the demanding specifications.

Beyond the technical aspects, the human element plays a significant role. Seeing the finished tanker – a massive structure built using the aluminum sheet we produced – brings a unique sense of pride. Knowing our meticulous work contributes to a safer, more efficient transportation system is deeply satisfying. However, there's also a constant awareness of responsibility. The integrity of the tanker, and ultimately the safety of the people and environment it interacts with, depends on the quality of our aluminum sheets. This motivates us to continuously improve our processes and maintain the highest standards, striving for excellence in every aspect of production.

-

Superior Strength-to-Weight Ratio: One of the standout aspects of 5083 is its exceptional strength-to-weight ratio. Compared to steel, aluminum is significantly lighter, which is particularly advantageous in tanker construction, allowing for increased cargo capacity and improved fuel efficiency.

-

Corrosion Resistance: Given that tankers are frequently exposed to seawater, corrosion resistance is a vital property. 5083 aluminum alloy is highly resistant to corrosion, significantly minimizing maintenance costs and thereby extending the lifespan of the vessel.

-

Weldability: Aluminum's inherent lightness can sometimes come at the cost of its weldability; however, 5083 is renowned for its excellent welding characteristics. This allows for versatile design alterations and modifications during construction, facilitating custom models catered to specific transportation needs.

-

Temperature Resistance: 5083 aluminum can also sustain structural integrity in varying temperature conditions, making it well-suited for transporting substances that may experience extreme thermal fluctuations.

Applications of 5083 Aluminum Alloy in Tanker Construction

Now that we understand the unique features of 5083 aluminum alloy, let's d

-

Chemical and Liquefied Gas Tankers: Due to its exceptional corrosion resistance and robustness, 5083 is commonly used in chemical and liquefied gas tankers. It enables operators to handle acidic, alkaline, and other reactive materials without worrying about material compromise.

-

Marine Vessels for Fishery and Fish Processing: In the fishing industry, large tankers often transport both live stock and processed products. The lightweight nature of 5083 leads to faster, more fuel-efficient vessels, reducing operational costs. Furthermore, its resistance to corrosion ensures hygiene and quality in food transport.

-

Insulated Tankers: When dealing with temperature-sensitive liquids, insulation is essential. 5083 aluminum is suitable both for the structure itself and as a component of insulated tanker designs, enhancing the retention of temperature-sensitive commodities.

-

Military and Defense Applications: In defense, durability and light-weight material are crucial. Aluminum tankers made from 5083 allow for greater mobility and flexibility in military operations, enabling efficient transport for a variety of strategic materials.

-

Luxury Yacht Tanks: It’s not all about commercial applications; 5083 is also prevalent in the luxury yacht industry. These vessels frequently require large tanks for fuel and water storage that must contend with marine conditions, where corrosion and weight are critical considerations.

Concluding Thoughts

The application of 5083 aluminum alloy in tanker design represents a pivotal advancement in maritime engineering. Its blend of lightweight, strength, corrosion resistance, and adaptability solves numerous pain points conventional materials offer while facilitating increased efficiency and safety. As the maritime industry continues to evolve, incorporating advanced materials like 5083 aluminum alloy ensures that tankers remain efficient and resilient in their quest to meet ever-growing global demands.

Choosing the right material can mean the difference between operational longevity and disaster. With 5083 aluminum sheet leading the way in tanker construction, forward-thinking brands and companies can expect significant benefits from their investment in this versatile and robust solution.

https://www.al-alloy.com/a/5083-tanker-with-aluminum-sheet.html