Gold anodized aluminum sheet

The Golden Edge: Unveiling the Functions and Applications of Gold Anodized Aluminum Sheets

In the realm of modern design and architecture, the unique aesthetic qualities of gold anodized aluminum sheets have captured the imagination of both designers and architects alike. With its striking visual appeal and robust performance, this metallic canvas offers an array of functionalities that suit various applications. By the distinctive features of gold anodized aluminum, one can appreciate why it has become a favored choice for projects requiring not only beauty but also longevity in demanding environments.

Gold anodized aluminum sheet presents a unique set of challenges and opportunities compared to other anodized finishes. The achievement of a consistent, rich gold tone is highly dependent on the alloy composition of the aluminum substrate. Slight variations in the aluminum's purity or trace elements can significantly impact the final color and its uniformity across a sheet. Furthermore, achieving a durable, scratch-resistant gold finish often requires a multi-stage anodizing process, including careful control of voltage, current density, and the electrolyte bath's composition. We've found that even minor deviations in these parameters can result in uneven coloring, pitting, or a lack of depth in the gold hue. This necessitates meticulous process control and regular quality checks throughout the entire production line, adding complexity and impacting overall throughput.

Beyond the production complexities, the market demand for gold anodized aluminum dictates a different approach to quality control. The subjective nature of "gold" – ranging from pale champagne to deep amber – requires precise color matching standards and sophisticated colorimetric analysis to meet customer expectations. We utilize spectrophotometers to ensure consistent color throughout batches and between different production runs. Furthermore, the intended application heavily influences the required surface properties. A gold anodized sheet for decorative purposes might prioritize aesthetic appeal, while applications in electronics might necessitate higher corrosion resistance or specific surface hardness. these nuanced requirements and tailoring the anodizing process accordingly is crucial for delivering a high-quality, customer-satisfying product.

Gold Anodization: Beyond Aesthetics

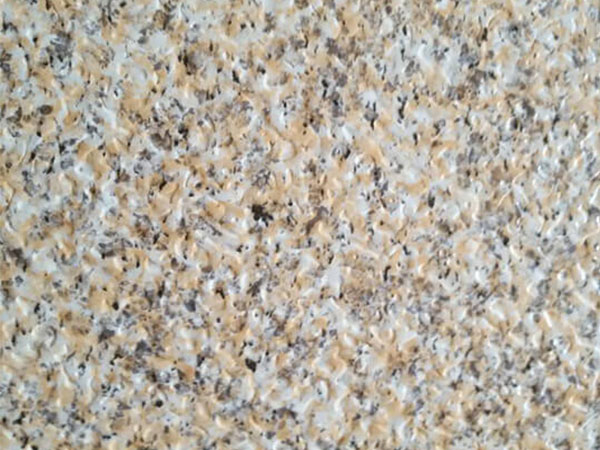

At its core, the anodization process is an electrochemical treatment that thickens the natural oxide layer on aluminum surfaces. This process enhances resistance to corrosion, wear, and scratching, ensuring that the material not only shines but also remains durable in harsh conditions. When aluminum is anodized in a gold hue, it adopts a unique metallic luster calibrated to various shades that resonate with warmth and sophistication. The resulting surface encapsulates the brilliance of gold, evoking a sense of luxury without the inherent fragility associated with pure metals.

What sets gold anodized aluminum apart technically is its exceptional level of customization; manufacturers can tailor the anodization process to achieve desired thickness levels that can range from 0.12 to 0.25 mils. This adaptability can cater to aesthetic desires while still providing protective qualities. The anodic layer also offers UV resistance, preventing fading over time—an invaluable trait for architectural finishes that combat the sun’s relentless rays.

Applications Across Industries: Beauty Meets Durability

The applications of gold anodized aluminum sheets span several sectors, with their eye-catching finish perfectly complementing functionality. Here are a few pioneering uses that showcase their versatility:

-

Architecture and Facades: In contemporary architectural designs, facade treatments are crucial for aesthetic appeal and structural integrity. Gold anodized aluminum sheets serve as cladding materials that reflect sunlight beautifully and fantastically alter a building’s visual identity. Systems designed with these panels improve energy efficiency by reflecting solar gains while adding a layer of elegance to commercial buildings, public monuments, and private residences alike.

-

Interior Design and Decor: In interior design, gold anodized aluminum has found its way into various decorative elements, ranging from wall panels to elegant light fixtures. Designers embrace this material for not only its durability but also for the warm ambiance and sophistication it imparts to interior space.

-

Consumer Goods and Accessories: Beyond large-scale applications, gold anodized aluminum finds its role in consumer products, from high-end gadgets to chic kitchenware. Its lightweight nature combined with resilience and style makes it an apt choice for those looking to add a touch of elegance to everyday objects, while still enjoying long-lasting quality. Items like drinkware, electronics casings, and art installations exemplify the melding of trends in consumer design with sustainable materials.

-

Automotive Components: The allure isn't just limited to aesthetic applications; it extends to technical utilities. Gold anodized aluminum sheets are also applied in automotive interiors where luxury elements, such as knobs and trims, require a blend of visual appeal and functional robustness. Utilizing anodized aluminum adds to durability while resisting scratches and imperfections over time.

-

Creative Art and Functionality: Artists and designers are increasingly finding innovative ways to incorporate gold anodized materials into their works. From sculptures to signage, the reflective quality of anodized sheets can imbue various forms of art with a sense of luxury and depth, leaning towards modern artistry while ensuring durability.

https://www.al-alloy.com/a/gold-anodized-aluminum-sheet.html