1060 Pure 0.15mm Aluminium Sheet

When it comes to precision fabrication and unique material properties, 1060 Pure Aluminium Sheet measures up remarkably. With a thickness of just 0.15mm, this alloy offers numerous advantages making it a preferred choice across various industries.

Features of 1060 Pure Aluminium Sheet

Exceptional Purity

The most notable feature of 1060 aluminium is its exceptional purity. Composed of at least 99.60% aluminium, this alloy promises outstanding corrosion resistance, high thermal and electrical conductivity, and remarkable malleability. These properties are essential in many applications, enabling reliable performance under diverse conditions.

Lightweight and Durable

At a density of approximately 2.7 g/cm³, 1060 aluminium sheets are incredibly lightweight compared to other metals, making them ideal for situations where weight reduction is crucial. Despite this lightness, the durability of the material cannot be understated. It strikes a balance between flexibility and strength, facilitating ease of handling during manufacturing processes.

Easy to Fabricate

One of the standout characteristics of 1060 0.15mm aluminium is its exceptional workability. This alloy can be easily shaped, cut, and formed without losing its structural integrity, providing manufacturers the opportunity to create intricate designs and components with precision. This malleability ensures that it can be seamlessly integrated into various products.

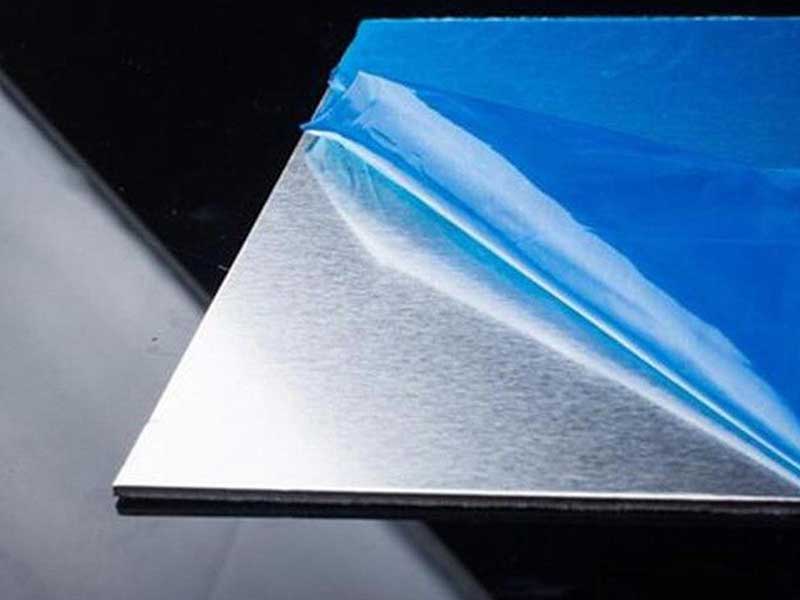

Surface Finish Quality

Another vital feature of 1060 Pure Aluminium is its superior surface quality, which allows for excellent finishing results. The smooth, clean surface of the sheet ensures that it paints and anodizes well, enhancing aesthetic appeal while also serving functional purposes in preventing corrosion.

Applications of 1060 Pure 0.15mm Aluminium Sheet

Philosophically, the use of 1060 Pure Aluminium Sheet is pervasive across numerous sectors. Its unique properties lend themselves to a variety of functional tasks, demonstrating remarkable versatility. Below are some principal applications:

Electronics

In the electronics sector, the high electrical conductivity of 1060 Pure Aluminium makes it excellent for manufacturing components such as heat sinks, capacitors, and casings for electrical devices. Given its lightweight nature, it enhances the efficiency of electronic devices by minimizing overall weight without compromising effectiveness.

Packaging

The packaging industry also champions 1060 aluminium sheets due to their impressive barrier properties and corrosion resistance. Thin sheets are often used for food wrapping and beverage containers, ensuring that products retain their freshness while remaining undamaged and safe for consumer use.

Architectural Applications

The aesthetic versatility of 1060 Pure Aluminium allows for its use in architectural structures and decorative products. Lightweight yet striking, 1060 can easily be produced in intricate designs for facades, wall panels, and facings, transforming modern spaces with an efficient and appealing element.

HVAC and Transportation

Furthermore, this alloy's ability to endure varying temperatures makes it useful in heating, ventilation, and air conditioning (HVAC) systems. Its lightweight structure minimises the overall weight in transportation applications, such as vehicle exteriors, promoting enhanced fuel efficiency without losing robust performance.

Medical and Industrial Equipment

Lastly, due to its non-toxic characteristics, 1060 Pure Aluminium is broadly employed in the manufacture of medical equipment, laboratory consumables, and https://www.al-alloy.com its lightweight nature, robustness, and extensive usage across sectors, the efficiency and effectiveness of 1060 aluminium Sheets exemplify why they are entrusted in high-standard industries.

https://www.al-alloy.com/a/1060-pure-015mm-aluminium-sheet-200.html