1060 3003 5052 Coating Aluminum Coil

1060, 3003, 5052 Coating Aluminum Coil: Features and Applications

Introduction

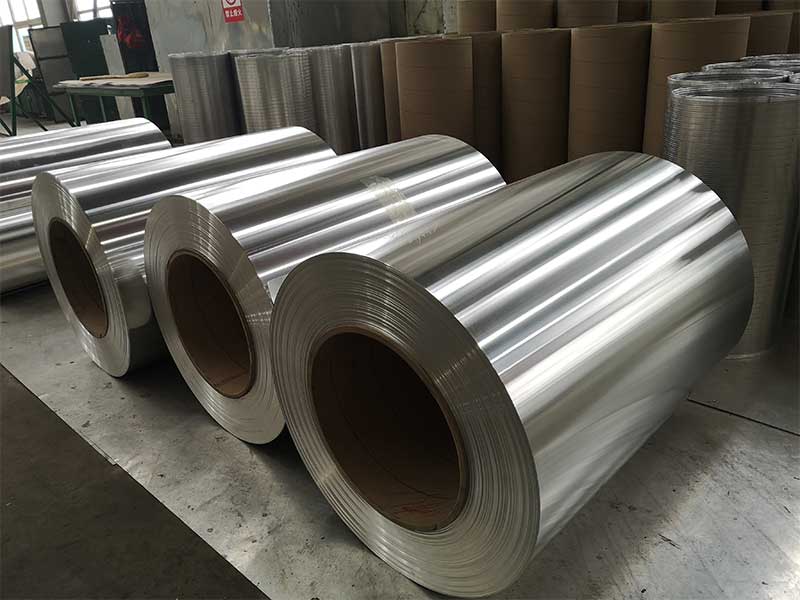

Aluminum coils have become integral materials in a variety of industries, owing to their lightweight, durability, and corrosion resistance. Among these, 1060, 3003, and 5052 are widely recognized aluminum alloys with particular traits that make them preferable for protective and decorative surface applications.

Features of 1060, 3003, and 5052 Coating Aluminum Coil

1060 Aluminum Coil

The 1060 aluminum alloy is renowned for its high purity, containing a minimum of 99.6% aluminum. This has several notable features:

- Excellent Corrosion Resistance: It has an exceptional resistance to atmospheric and chemical corrosion, making it ideal for external applications.

- High Electrical Conductivity: The alloy exhibits high electrical conductivity which is beneficial for applications in electrical conductors.

- Remarkable Workability: It can be easily shaped and fabricated, enabling complex designs without compromising integrity.

3003 Aluminum Coil

The 3003 aluminum alloy is classified as a general-purpose aluminum alloy with moderate strength, providing a balance between usability and durability. features include:

- Malleability: This alloy has excellent malleability that allows it to be shaped without cracking, making it suitable for a range of fabrications.

- Good Corrosion Resistance: Similar to 1060, 3003 maintains solid resistance against corrosion, although it is often used in less aggressive environments.

- Increased Strength: Compared to 1060, this alloy features added strength that supports greater working loads while remaining lightweight.

5052 Aluminum Coil

Known for its strength and versatility, the 5052 aluminum alloy is well-regarded in numerous applications. Its standout features include:

- Exceptional Fatigue Resistance: This alloy can withstand repeated loading without failing, making it optimal for structural applications.

- Good Weldability: It is known for its excellent weldable quality, facilitating use in fabrication operations.

- Enhanced Corrosion Resistance: The strong resistance properties, particularly against saltwater, make it highly suitable for marine applications.

Applications of Coating Aluminum Coils

Architectural Applications

The aesthetic qualities of aluminum coils, coupled with their durable nature, make them suitable for architectural applications. The 1060 alloy is particularly prized in external cladding, facades, and roofing where appearance is vital without sacrificing function. The 3003 alloy also finds its place in decorative finishes, providing both functionality and design flexibility.

Electrical Industry

Owing to its excellent conductivity features, the 1060 aluminum coil is commonly used in various electrical applications including electrical conductors and transits. Its reliability plays a pivotal role in maintaining performance in electrical systems.

Marine and Automotive Industries

The corrosion resistance and structural integrity of the 5052 aluminum coil make it widely used in the marine and automotive sectors. Applications in boat docks, trailers, and car parts benefit from this alloy’s durability against harsh environmental conditions.

Packaging and Fabrication

Both 3003 and 5052 coils are exploited for their formability in packaging, where they can be easily rolled and λformed for containers, cans, and other products. The malleability of 3003 is particularly beneficial in creating parts that require intricate shapes for functional packaging solutions.

https://www.al-alloy.com/a/1060-3003-5052-coating-aluminum-coil.html