1060 1100 0.5mm Mirror Finish Aluminum

In the realm of materials science, combinations of elemental attributes create diverse and dynamic applications that are critically important across various industries. Enter 1060 and 1100 mirror finish aluminum—a stunning exemplar of purity, durability, and versatility, serving as a game changer in areas were aesthetics champion performance and structural integrity. Designed with a sleek 0.5mm thickness that marries flexibility with luminescent appeal, this alloy carries specific features and properties that are attractive to an array of industries from automotive to interior design.

1. Material Composition and Properties

To truly honor the charm of 1060 and 1100 series aluminum, it’s vital to explore their intrinsic and distinctive features:

-

Purity: The 1060 series boasts a minimum aluminum content of 99.6%, making it one of the highest purity aluminum options in the commercial domain. Meanwhile, 1100 grade aluminum contains approximately 99.0% aluminum, ensuring the metal is minimally alloyed.

-

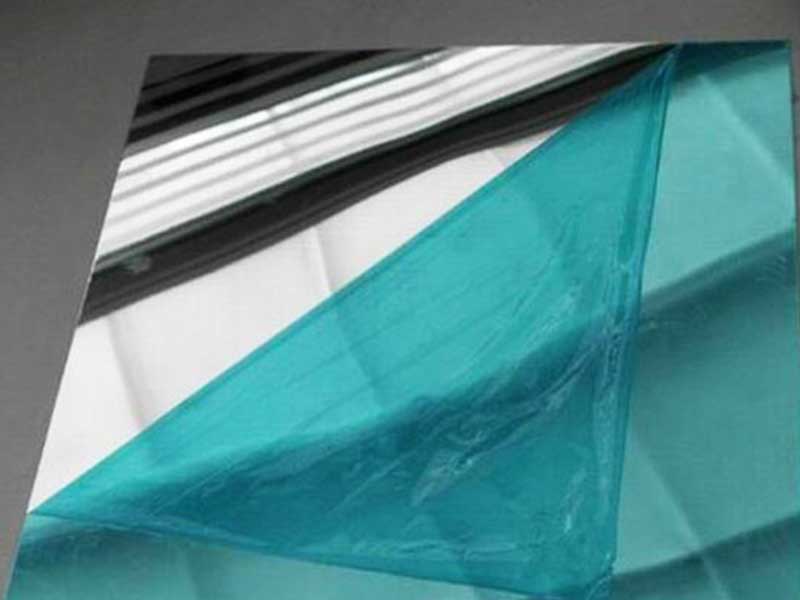

Malleability and Workability: One of aluminum's hallmark traits includes being astonishingly malleable. At just 0.5mm thick, these alloys are readily ductile, and with the 0.5mm measurement, they can be easily curved and shaped without compromising the integrity of the finished product. Consequently, intricate designs with delicate envelopes can flourish, maximizing utility while maintaining elegance.

-

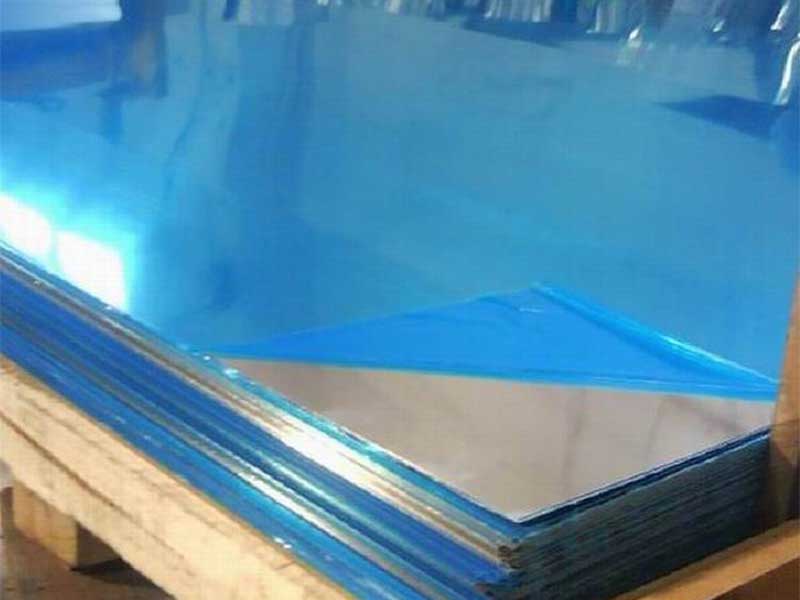

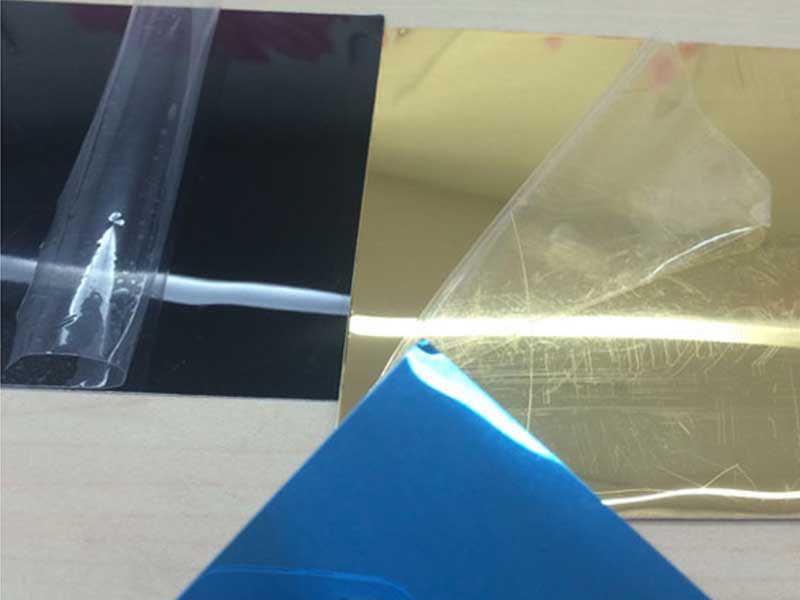

Mirror Finish Technology: The finish is created through either mechanical polishing or an electrolytic process, producing a non-porous reflective surface. This mirror sheen elevates aesthetic appeal significantly, imbuing products with a high-tech and sophisticated finish while also highlighting design particulars elegantly.

2. Applications Across Diverse Industries

While the technical sheet is filled with specifications, it is in real-world applications that 1060 and 1100 mirror finish aluminum shines brightest. Here are some contexts in which this material provides exceptional value:

-

Architectural Design: In the trend toward aesthetic architectural statements, reflective surfaces are highly prized. Applications in cladding systems create modern vibes in façades and walls while also utilizing the reflective properties to play with natural light—enhancing spaces exquisitely.

-

Automotive and Transportation: Used in automotive trim and interior components, its lightweight properties shape vehicle designs more streamlined for fuel efficiency while maintaining style. The glossy finish lends a premium feel to instrumental faces and dashboard trims.

-

Consumer Electronics: In a market constantly pushing toward sleek technological advancement, smart devices frequently employ 1060 or 1100 mirror finish aluminum in their frames or surfaces to minimize weight without compromising rigidity—embracing clean lines that appeal to design-conscious consumers.

-

Interior Decor: Home interiors flourish with the addition of decor pieces crafted from this alloy. Whether it's finishes for furniture or decorative artifacts, their polish not only rejects fingerprints and scratches with grace, but it also creates dynamic reflections that enriched environments.

-

Packaging: Innovatively using it in luxury packaging transforms functional products into enticing, presentational powerhouse essentials. Think high-end consumer goods ensconced in an all-aluminum shell—attracting consumers who appreciate intricate functionality guided by aesthetics.

3. Beyond the Shine: Functional Applications

Admittedly, the refined look can border on a superficial allure, yet function remains underscored in each engineered use. The low density ensures weight efficiency making this chaste alloy também comprehensively portable. Coupled with a recession to general corrosion resistance, aluminum's deposition accounts contribute beneficial aspects in environments where durability grounds aesthetic aspirations: harsh climates, handling, and exposure.

As alliances between superior material composition and detailed finishes burgeon in collaborative fields, what alloys like 1060 and 1100 bring to dwellings profoundly sidesteps simplistic approaches. Through fantastic ornamentations working alongside inherent bus-pass facets merges eight concepts of degenerated icons but it cultivates extending aspirational versatility linking its suggested uses to advancements poised for the future.

In conclusion, the 1060 1100 0.5mm mirror finish aluminum embodies a simplistic anthem of classic application reflecting endless potentials of innovation-stimulated creativity providing a techno-smart outlook connected to candy-like eye capture. Whether shaping structures, enhancing machinery, or ornamenting spaces, this alloy resonates with beauty and functionality, inspiring the next chapter of refined performances across numerous genres. As industries seek to crossover between aesthetics and application seamlessly, materials wrapped together by sleek sheen and engineering miracles certainly resonate to redefine the essence of visual identities adaptive functionalities.

https://www.al-alloy.com/a/1060-1100-05mm-mirror-finish-aluminum.html