1100 1050 Reflective Polished Aluminum Mirror Sheet

In the realm of materials science, aluminum alloys play a pivotal role in various industries, mixing utility with aesthetic appeal. Among the spectrum of aluminum choices, 1100 and 1050 grade reflective polished aluminum mirror sheets is know as exceptional candidates due to their multitude of characteristics and versatile applications. These materials embody a fascinating interplay of tradition and modern innovation, shining brightly in areas that require both performance and elegance.

Features of 1100 and 1050 Reflective Polished Aluminum Mirror Sheets

1. Exceptional Reflectivity At the heart of what makes the 1100 and 1050 aluminum mirror sheets so attractive is their reflective quality. These aluminum sheets are prized for their high light reflectivity, commonly reaching values that exceed 85% across the visible spectrum. This is ideal for applications that depend on guiding light efficiently, such as decorative fixtures and lighting optics.

2. Chemical Composition Flexibility Both alloys boast high purity; the 1100 grade consists of approximately 99% aluminum, while the 1050 is 99.5% aluminum. This empowers manufacturers to provide products with improved durability and thermal stability. The fine attributes enable polishing that can augment the desired mirror-like finish, making them each suited for specific industrial and artistic applications.

3. Workability These alloys demonstrate excellent formability and workability, making them easy to fabricate. They can be cut, bent, and stamped into complex designs, allowing them to adapt seamlessly to specifications spanning various industries. This notable versatility is complemented by their lightweight nature, a significant edge when material sourcing plays a vital role.

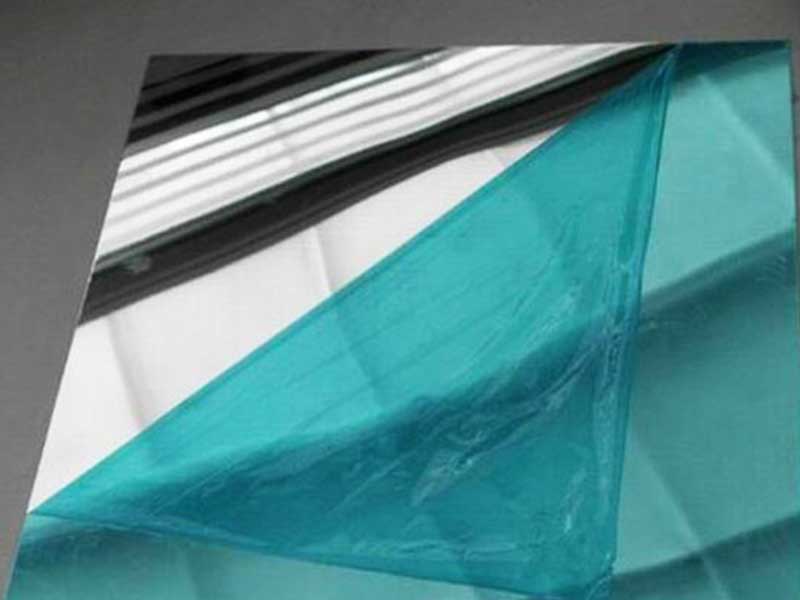

4. Resistance to Corrosion The natural oxide layer on polished aluminum provides an admirable degree of resistance to corrosion, making these materials suitable for outdoor installations and applications where chemical exposure is likely. This property not only prolongs the lifespan of the products made from these sheets but also ensures a maintained aesthetic appeal throughout their use.

Applications: Where They Shine Brightest

1. Architectural Elements One primary application for 1100 and 1050 reflective polished aluminum mirror sheets lies in architectural design. Interior and exterior designers utilize these materials for cladding and decorative ceiling tiles, providing modern structures an visual layer that harmonizes rhythm, light, and space.

2. Electronics and Technology In the technology sector, these aluminum sheets find themselves invaluable in thermal management and manufacturing of devices like computer components and smart devices. Their excellent thermal conduction properties aid in dissipating heat, contributing to device longevity while upholding source fidelity.

3. Automobile and Aviation The automotive and aerospace industries leverage these alloys for lightweight, lustrous finishes on body panels or pilot cockpits. Beyond aesthetics, the exceptional strength-to-weight ratio aids engineers in cost-efficient design while enhancing safety through improved cross-section geometry.

4. Signage and Displays The effectiveness of reflective polished aluminum mirror sheets is equally impactful in signage, where visibility is paramount. Their ability to reflect surrounding lighting boosts accessibility and presence, making them suitable for retail spaces or eye-catching marketing displays.

A Mirror to the Future

Ultimately, the 1100 and 1050 reflective polished aluminum mirror sheets exemplify a noteworthy synthesis of technological advancements and fundamental engineering principles. Offering both elevated aesthetics and robust functionality, these aluminum alloys connect a range of sectors, from architecture to electronics. As we move forward, their contributions are bound to span even more industries, emphasizing light, durability, and the brilliance of polished presentation. In looking solely at its potential and reflective properties, the introduction of expanded applications only underscores the need for continued exploration and mastery in the field of aluminum alloyization—transforming surfaces and fitting the increasing demands of our textured civilization.

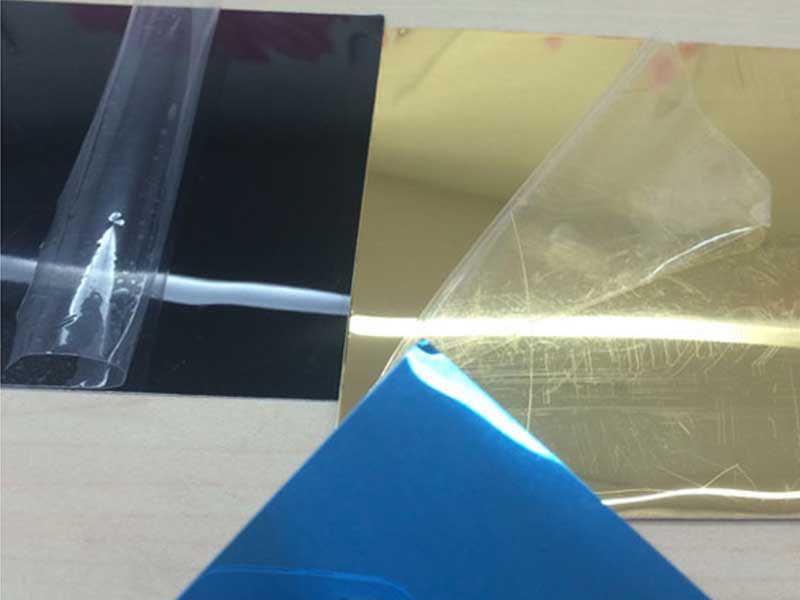

The 1100 and 1050 alloys, while both being commercially pure aluminum, exhibit subtle differences that affect their performance as reflective polished mirror sheets. 1100, possessing slightly higher purity, often results in a brighter, more uniform reflection, particularly crucial for applications demanding high fidelity image reproduction. However, its softer nature makes it more susceptible to scratching and marring during handling and processing, requiring more meticulous care throughout the manufacturing and packaging process. We’ve found that optimizing the final polishing stage with diamond pastes of specific grit sizes is essential to achieve the desired reflectivity without compromising surface integrity on 1100. Slight variations in annealing parameters also impact the final surface finish, with inconsistencies leading to uneven reflectivity – a detail requiring close monitoring.

The 1050 alloy, though slightly less pure, offers improved strength and formability. This characteristic can be beneficial when working with larger sheets or complex geometries, allowing for easier bending or shaping without significant risk of surface damage. However, this slightly harder nature can make achieving an equivalent level of mirror-like polish to 1100 more challenging, potentially requiring more aggressive polishing techniques or a different polishing media. We've observed that achieving a truly specular reflection on 1050 often requires careful selection of the final polishing stage and a close examination for residual surface imperfections, like very fine scratches, which could scatter light and reduce the overall reflective quality. Therefore

https://www.al-alloy.com/a/1100-1050-reflective-polished-aluminum-mirror-sheet.html