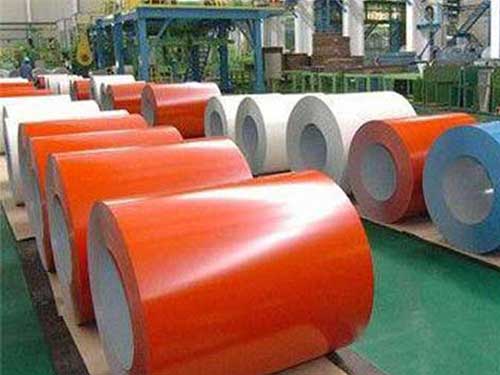

Color Coated Aluminum Coil 1060, 1100

Color coated aluminum coils have gained immense popularity in various fields due to their versatility, durability, and aesthetic charm. Among the most commonly used alloys are 1060 and 1100 aluminum coils.

Features of Color Coated Aluminum Coil 1060 and 1100

1. High Durability

Both 1060 and 1100 aluminum coils offer exceptional durability, making them resistant to bending, destruction, and corrosion. Their natural non-rusting property prolongs their lifespan, a characteristic essential for applications exposed to harsh weather conditions.

2. Excellent Formability

One of the defining features of the 1060 and 1100 alloys is their excellent formability. They can be easily shaped and molded, making them suitable for a wide array of fabrication processes, from rolling to stamping. This makes them preferable in decorative applications through custom designs.

3. Lightweight

When it comes to weight-to-strength ratio, aluminum always shines. The lightweight property of 1060 and 1100 aluminum coils enhances their utility across various applications without compromising strength and performance.

4. Aesthetic Flexibility

The color coating on aluminum coils generates an aesthetically pleasing surface that is scratch-resistant and can mimic numerous textures and finishes. This quality is crucial for products needing visual appeal, allowing an array of color options to fit diverse design requirements.

5. Reflectivity

Both alloys offer exceptional reflectivity, which is particularly important in energy-saving applications such as roof coatings or reflective panels. With increased HVI (Heat Ventilation Index), using these coils can help minimize energy consumption in buildings.

Applications of Color Coated Aluminum Coil 1060 and 1100

1. Building and Construction

The use of 1060 and 1100 aluminum coils in the construction industry is significant. Their excellent durability, corrosion resistance, and aesthetic flexibility make them ideal for exterior wall cladding, roofing materials, and decorative elements in modern architecture.

2. Sign Manufacturing

Color coated aluminum coils are a popular choice in sign making. The lightweight property allows for easier installation and transport, while the variety of colors available means businesses can create stunning visual appeal for promotional signs and banners.

3. Home Appliances

Another noteworthy application is in the manufacturing of home appliances such as refrigerators, air conditioners, and washing machines. The color-coated coils are not only lightweight but also apt for providing a modern look to various appliances.

4. Automotive Industry

In the automotive sector, combining the lightweight nature and durability of 1060 and 1100 aluminum coils leads to enhanced fuel efficiency in vehicles. These coils may be used in decorative trim, as well as in non-structural components, representing the blend of functionality and style.

5. Interior Decoration

The aesthetic versatility of color coated aluminum coils leads them to be utilized in interior design. They can be fashioned into elegant ceiling tiles, wall panels, and various fixtures, enhancing both residential and commercial interiors with modern visual elements.

https://www.al-alloy.com/a/color-coated-aluminum-coil-1060-1100.html