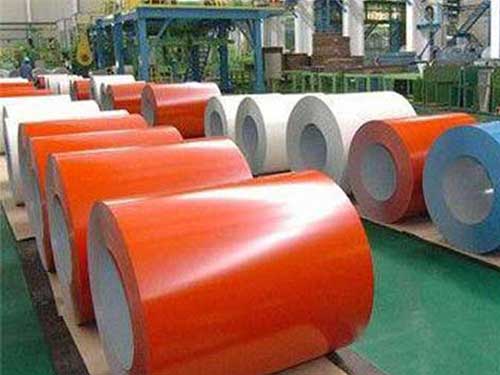

1060 3003 5052 8011 color coated aluminium coil

Aluminium coils are an essential part of various industries due to their lightweight, corrosion-resistant properties. Among the many grades of aluminium available today, 1060, 3003, 5052, and 8011 stand out with their unique characteristics and versatile applications.

Understanding Aluminium Grades

1. 1060 Aluminium Coil: The 1060 alloy is renowned for its high purity, boasting a minimum aluminum content of 99.6%. This grade is lightweight and highly workable, making it an excellent choice for applications where corrosion resistance and good ductility are vital. In terms of color coating, 1060 aluminium coils are popular in architectural applications, where aesthetically pleasing finishes are desired.

Common Applications:

- Building facades and roofing

- Interior decorative panels

- Electrical applications due to its excellent conductivity

2. 3003 Aluminium Coil: The 3003 alloy boasts excellent corrosion resistance and workability. Composed mainly of aluminum with about 1.2% manganese, this grade provides enhanced strength and is more suitable for forming and welding. Color coated 3003 aluminium coils are commonly used where both strength and aesthetic appeal are essential.

Common Applications:

- Cooking utensils and equipment

- Chemical equipment and tanks

- Decorative ceiling tiles

3. 5052 Aluminium Coil: 5052 is a marine-grade aluminium alloy. Known for its high strength and corrosion resistance, particularly in marine environments, it incorporates about 2.5% magnesium. When coated, 5052 coils offer excellent durability while allowing for vivid colors and intricate designs. Their strength makes them suitable for applications requiring increased endurance.

Common Applications:

- Boat hulls and parts

- Transportation sectors (trailers, trucks)

- Decorative elements in architectural designs

4. 8011 Aluminium Coil: Primarily used in the production of food containers and flexible packaging, the 8011 alloy features exceptional formability and is crucial in the packaging industry. Known for its low density, this alloy can also be coated in various colors, making it not only functional but visually appealing in applications such as seamless packaging designs.

Common Applications:

- Food and beverage packaging

- Household aluminium foil products

- Pharmaceutical packaging materials

Benefits of Color Coated Aluminium Coils

Whether it’s 1060, 3003, 5052, or 8011, color coating provides several important benefits:

- Aesthetics: Color coated coatings can mimic other materials, allowing for creative design while maintaining the lightweight properties of aluminium.

- Weather Resistance: The coating shields the metal from environmental factors such as UV rays and moisture, enhancing longevity.

- Corrosion Resistance: The color coating acts as a barrier to prevent oxidation and deterioration, especially important in outdoor applications.

- Easy Maintenance: Coated surfaces are easier to clean and maintain compared to traditional metals.

https://www.al-alloy.com/a/1060-3003-5052-8011-color-coated-aluminium-coil.html