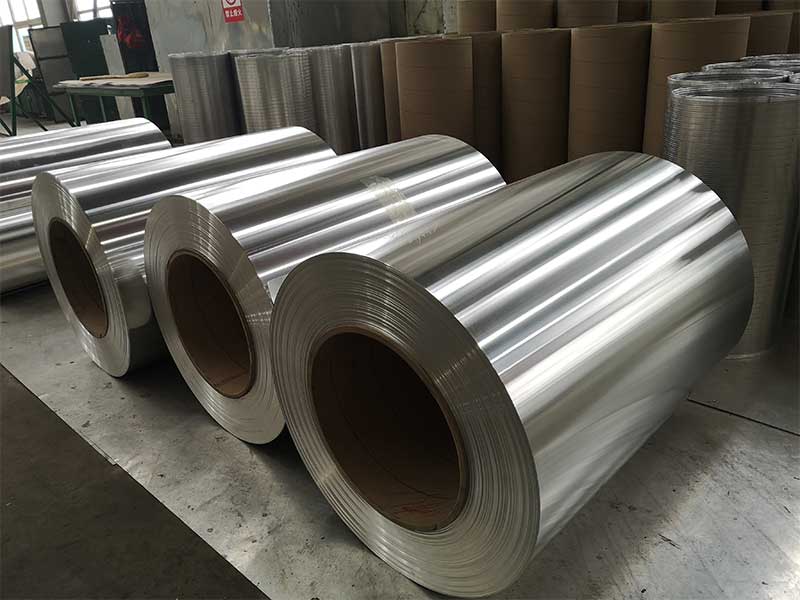

Aluminum coil 6 Micron 6.35 Micron 7 Micron

Aluminum coils have gained significant attention in various industries due to their remarkable properties and versatility. A popular choice among manufacturers and consumers alike, aluminum coils in thicknesses such as 6 Micron, 6.35 Micron, and 7 Micron provide a plethora of applications, ensuring their vital role in modern technology and architecture.

Features of Aluminum Coil

1. Lightweight Composition

One of the most significant features of aluminum coils—particularly those at lower thicknesses like 6 Micron and 7 Micron—is their lightweight nature. This characteristic not only makes them easy to handle and install but also contributes to lower costs in terms of transportation and production. For industries such as aerospace and automotive, utilizing lightweight materials is a critical factor in enhancing fuel efficiency and performance.

2. High Durability

Despite their thin profiles, aluminum coils deliver exceptional strength and durability. The engineering marvel of the 6.35 Micron thickness allows these coils to resist corrosion and withstand environmental challenges, ensuring long-lasting performance. Their ability to maintain form under stress also makes them an indispensable choice in high-demand applications.

3. Excellent Thermal Conductivity

Aluminum coils, especially those around the spec of 6 Micron, are well-known for their excellent thermal conductivity. This property is particularly advantageous in applications such as heat exchangers or thermal management systems where efficient heat transfer is paramount. Industries like HVAC benefit significantly from aluminum coils because they help enhance system performance.

Applications of Aluminum Coil

1. Packaging Solutions

One of the leading applications of aluminum coils is in producing high-quality packaging materials. With the increasing demand for sustainable and lightweight options, thin aluminum coils—such as those measuring 6.35 Micron—are frequently used in the food and beverage industry. These coils effectively protect contents from moisture and preserve the freshness of products, all while being recyclable and eco-friendly.

2. Construction and Architectural Elements

The properties of aluminum coils make them ideal for architectural applications. Thin gauges like 6 Micron and 6.35 Micron are utilized in curtain walls, roofing, and composite panels. Their high resistance to corrosion allows them to be exposed to weather elements without degrading, ensuring buildings and structures possesses a durable and attractive façade.

3. Automotive Components

In the automotive industry, the quest for weight reduction without sacrificing strength is ongoing. Aluminum coils with thicknesses such as 7 Micron have generated favorable responses in vehicle manufacturing, contributing to better performance, reduced emissions, and increased fuel efficiency. Major applications include heat shields, radiator fins, and body panels where stiff yet lightweight materials are preferred.

4. Electrical Applications

Thanks to their excellent conductivity and formability, aluminum coils also find uses in various electrical applications. For manufacturing electrical conductors and components, the 6.35 Micron variants are suitably compliant, allowing manufacturers to produce wiring and connectors with optimal conductivity characteristics without added weight.

https://www.al-alloy.com/a/aluminum-coil-6-micron-635-micron-7-micron.html