3003 H14 Aluminum Sheet Aa1100

3003 H14 Aluminum Sheet (AA1100): Features and Applications

Aluminum has revolutionized countless industries with its unmatched versatility and exceptional properties. Among the varieties that is know is the 3003 H14 aluminum sheet—also designated as AA1100. This alloy, renowned for its workability and resistance to corrosion, serves as an unsung hero across varied sectors, tying function with finesse.

3003 H14 Aluminum Sheet (AA1100)

To grasp the features and applications of the 3003 H14 aluminum sheet effectively, it’s paramount to decode what those numbers mean.

- 3003: This designation indicates the alloy, typically comprising aluminum (approximately 96% or more) along with significant elements like manganese (starting contributions are 1.0 - 1.5%) that enhance strength and corrosion resistance.

- H14: This designation refers to the temper or treatment of the aluminum. H14 indicates that the material has been strain-hardened and partially annealed, resulting in a comparable balance of ductility and strength.

- AA1100: This is a common equivalent designation. While 1100 alloy is primarily pure aluminum, specifying it alongside 3003 highlights the close relationship between these aluminum series and their physical and mechanical properties.

Features of 3003 H14 Aluminum Sheet

-

Excellent Workability: The 3003 H14 alloy is exceptionally malleable, making it ideal for applications requiring bending, spinning, and molding without cracking. Crafting intricate shapes is seamless, which makes it ideal for a range of manufactures—from kitchens to bathroom fixtures.

-

Corrosion Resistance: One of the flagship features of aluminum going back to its natural oxidization is a unique ability to resist corrosion. This means 3003 H14 is apt for environments where access to moisture is high—think marine applications or outdoor designs.

-

Moderate Strength: While not as strong as some tougher aluminum alloys, 3003 H14 provides enough tensile strength to support a range of applications. Its flexibility allows it to stretch and adapt under various loads, promoting longevity without degrading quickly under pressure.

-

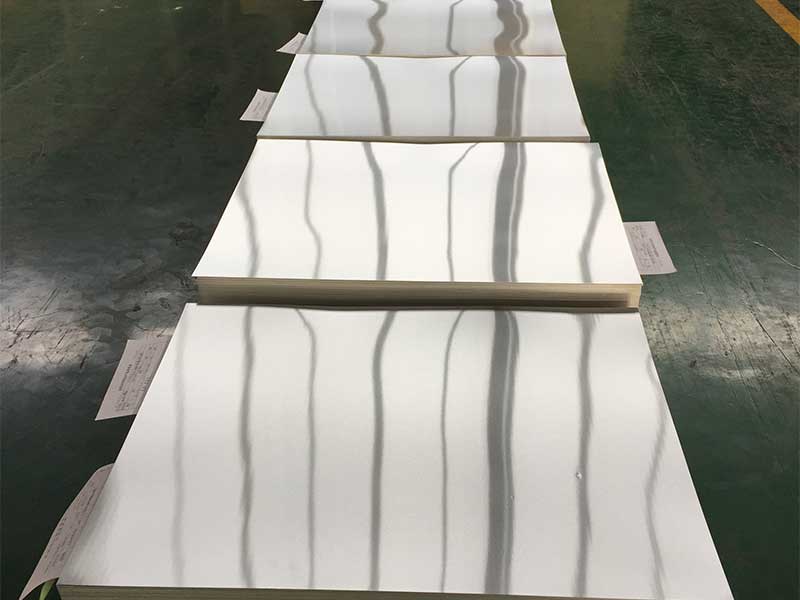

Appearance: The aluminum sheet comes with a natural finish and is easily treated to enhance its aesthetic appeal. This quality is attractive for applications in architecture and consumer goods—customers often appreciate an industrial product that carries aesthetic grace.

Applications of 3003 H14 Aluminum Sheet

The realm of applications for 3003 H14 aluminum sheets is vast, seamlessly blending its functionality in structural engineering and aesthetic into real-world products. Here’s a closer look at how industries harness this extraordinary material:

-

Cookware: The cooking industry values this aluminum grade, using it in the manufacturing of pots and pans due to its excellent thermal conductivity and non-stick properties.

-

Storage Tanks: In chemical industries, the corrosion resistance of 3003 H14 is a massive advantage when constructing storage tanks for chemicals prone to causing corrosion—offering safety without rust concerns.

-

Automotive: This aluminum is frequently used in bodywork and trims within the automotive sector. Its light weight supports fuel efficiency, while advanced safety and aesthetic features remain unhampered.

-

Architectural Applications: The aesthetic enhancement can be easily observed in architectural applications such as decorative ceilings and wall panels. Designers utilize panels fabricated from 3003 H14 to create stylish installations that can withstand outdoor elements without losing shine.

-

Electrical Enclosures: With a commendable degree of electrical conductivity, 3003 H14 aluminum sheets are essential in electronics, housing devices where safety is important and preserving the electrical integrity while minimizing heat.

https://www.al-alloy.com/a/3003-h14-aluminum-sheet-aa1100.html