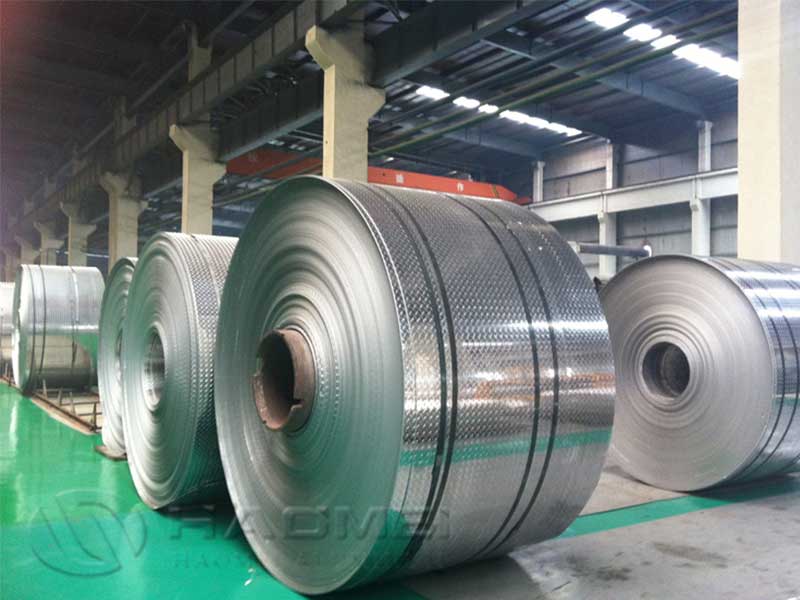

Alloy aluminum plate pattern aluminum plate

When one thinks about the glint of aluminum—under the harsh glare of a factory overhead light—it’s easy to overlook the nuanced complexity that lies beneath that shiny surface. Alloy aluminum plates, especially those boasting an exciting array of patterns, are the unsung heroes of countless industries. Buckle up as we take a leisurely stroll through the fascinating world of patterned aluminum plates, examining their functions and applications with a fresh perspective.

Alloy Aluminum Plate Patterns

So, what exactly is an alloy aluminum plate pattern aluminum plate? Picture this: traditional aluminum, mixed with various alloying elements like copper, magnesium, manganese, zinc, or silicon—resulting in a revolutionary blend stronger and lighter than its singular counterpart. Now, take that sturdy material and introduce patterns onto its surface. These could range from checkered surfaces to more intricate designs, and believe me, it's not just for aesthetics—though they certainly turn heads!

From a production standpoint, the "alloy aluminum plate pattern aluminum plate," or more simply, tread plate, is a fascinating beast. We're not just stamping out flat sheets here; the embossed pattern itself presents unique challenges. Getting the depth and consistency of those raised diamonds or bars right is crucial for both aesthetics and functionality. Too shallow, and the slip resistance is compromised; too deep, and you risk weakening the plate or having tooling failures. The alloy itself plays a huge role – different alloys offer varying degrees of strength, corrosion resistance, and workability, directly influencing the ease of production and the final product's lifespan. We constantly monitor material properties and adjust our processes accordingly to ensure consistent quality, which is especially critical when dealing with larger orders for specialized applications.

Beyond the production line, I've found the applications for this material incredibly diverse. It's not just for truck beds and walkways, as many assume. I've seen it used in everything from custom architectural features to specialized flooring in industrial settings. The inherent strength and anti-slip properties are highly sought after. Recently, we had a request for a modified pattern to improve grip for a client building specialized equipment for a food processing facility – those bespoke projects really highlight the versatility of even something seemingly mundane as patterned aluminum plate. It’s this constant evolution and application that makes working with this material both challenging and rewarding.

The patterns play a crucial functional role, too. They enhance grip, making these plates not just stylish, but safe to walk on. Imagine industrial settings where slip hazards abound—adding a textured surface acts like a mini lifeguard, reducing accidents.

The Multifaceted Functions of Patterned Aluminum Plates

-

Safety First: One of the standout characteristics of patterned aluminum plates is their excellent slip resistance. Industries such as aviation, shipbuilding, and automotive benefit massively from these plates. Saying goodbye to constant slips is like saying hello to smoother operations and decreased liability.

-

Aesthetic Appeal: Beyond the serious business of function, let's not forget that looks matter—even in industrial applications. By integrating aesthetically pleasing patterns, businesses can transform drab spaces into visually captivating environments. It’s all about keeping it functional while adding some flair.

-

Weight Management: Since teamwork makes the dream work, agility in varied settings often requires smart weight management. Patterned aluminum plates are ly lightweight given their durability. This gives them an edge in applications where heft can weigh down progress—like in modular buildings or transportation vehicles.

-

Corrosion Resistance: Various alloys used in patterned aluminum plates enhance corrosion resistance. This strength against the elements is especially nope-worthy for outdoor applications and marine environments, where salt and humidity take center stage. Trust me, if a plate can withstand environmental elements, it’s bound to stick around.

Where Do These Patterned Marvels Shine?

Now that we grasp the myriad functions, l

-

Transportation: They’re the unsung heroes in everything from airplanes to trailers. The combination of strength, lightweight nature, and grip makes them ideal for floors in trucks and railcars.

-

Architecture: Patterned aluminum has waltzed into architecture, offering durable yet lightweight cladding that upholds building aesthetics on a grand scale. Who thought functionality and beauty could be allies in constructing skyscrapers?

-

Marine Applications: The boating world loves patterned aluminum plates for decking due to their exceptional antiskid properties and resistance to rust. Keep those boats safe and stylish!

-

Industrial Flooring: Whether it's in factories or warehouses, to avoid accidents and streamline productivity, these plates are installed for superior safety while still looking good doing it.

https://www.al-alloy.com/a/alloy-aluminum-plate-pattern-aluminum-plate.html