14 gauge aluminum plate

In the world of engineering and construction, finding the right material can be the to a successful project. One material that often underlies the innovation in multiple industries is the aluminum plate, particularly a 14 gauge aluminum plate. Though the term "gauge" might seem technical, it specifies the thickness of the material—approximately 0.078 inches. This measurement plays a pivotal role in determining its usability, strengths, and functionality across diverse applications. Let's dive deeper from a unique vantage point into this versatile entertainer.

Lightweight yet Robust: The Magic of 14 Gauge Aluminum

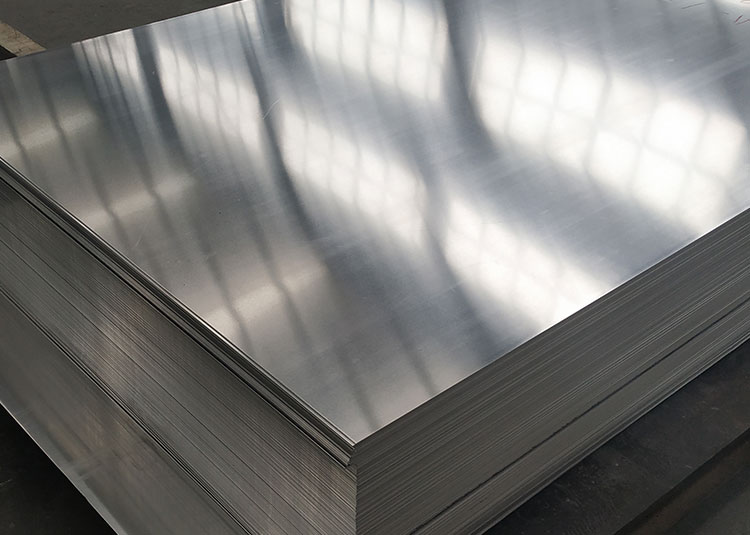

The classic attributes of aluminum—its lightweight nature and commendable strength—truly shine when we explore the 14 gauge variety. Weighing in at about 0.78 pounds per square foot, it provides an excellent strength-to-weight ratio. This characteristic makes the aluminum plate the go-to choice for industries where weight is a major constraint, such as aerospace and automotive sectors.

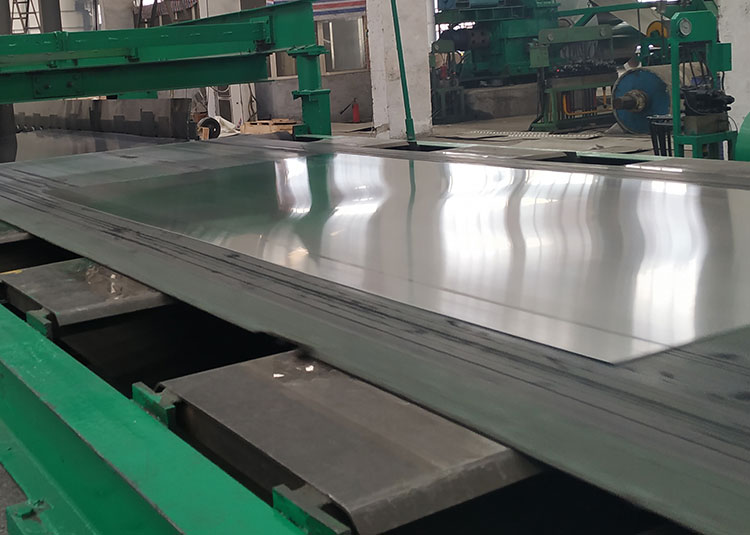

14 gauge aluminum plate presents a fascinating balance of workability and strength in our production line. Its relative thinness makes it easier to fabricate than thicker gauges, allowing for faster processing times on our stamping and bending machines. This translates directly to increased production efficiency and lower labor costs. However, this thinner profile also means it's more susceptible to deformation during handling and transport, requiring careful attention to stacking procedures and protective packaging to avoid scratches, dents, and warping, which are significant quality control issues. We've found that slight adjustments to our automated handling systems, including slower conveyor belt speeds and optimized robotic gripping mechanisms, were crucial in mitigating these problems.

A recurring challenge with 14 gauge aluminum plate lies in achieving consistent surface finish. While its malleability is beneficial for shaping, it also makes it prone to surface imperfections during processes like rolling and cutting. We've experimented with different cutting lubricants and optimized tooling geometries to minimize burring and scratching, and found a significant improvement in surface quality using a specialized diamond-tipped tooling alongside a high-pressure, low-viscosity cutting fluid. Furthermore, the inherent variations in the aluminum alloy itself impacts our ability to predict its behavior during these processes, necessitating close monitoring of raw material properties and consistent calibration of our equipment.

Unlike steel, which poses significant weights and corrosion challenges, the 14 gauge aluminum alleviates these issues while still providing necessary robustness. This aspect is especially utilized in aircraft components, where reducing weight contributes significantly to fuel efficiency and performance metric enhancements.

Versatile Jump-Start in Fabrication

Another remarkable function of the 14 gauge aluminum plate stems from its suitability in various fabrication methods. The Aluminum Association has verified the malleability of aluminum, which allows designers and engineers to cut, weld, punch, or bend into various shapes and sizes as required. This leads to reduced production times and enhanced versatility in project execution.

In the commercial kitchen industry, you'll find these aluminum plates in heavy-duty applications such as surfaces for counter-tops and equipment totes. Their resistance to corrosion alongside a non-stick cooking surface promotes hygiene standards while creating cooking improvement spaces.

Shelter and Structure

The construction industry stands as a testament to the durability and versatility of 14 gauge aluminum plates. As part of structural frameworks, roofing systems, and custom design elements, these plates often support significant aggregate loads, without being overly cumbersome. Architectural creativity takes further brilliance as anodized aluminum caters to aesthetic requirements while improving the durability of façades.

In particular, modern environmental designs juxtapose aesthetic appeal with probe functionality uses. The 14 gauge aluminum plates serve as fire-resistant walls in both architectural designs and functional energy-boosting materials, which fully comply with regulations while retaining decorative appeal.

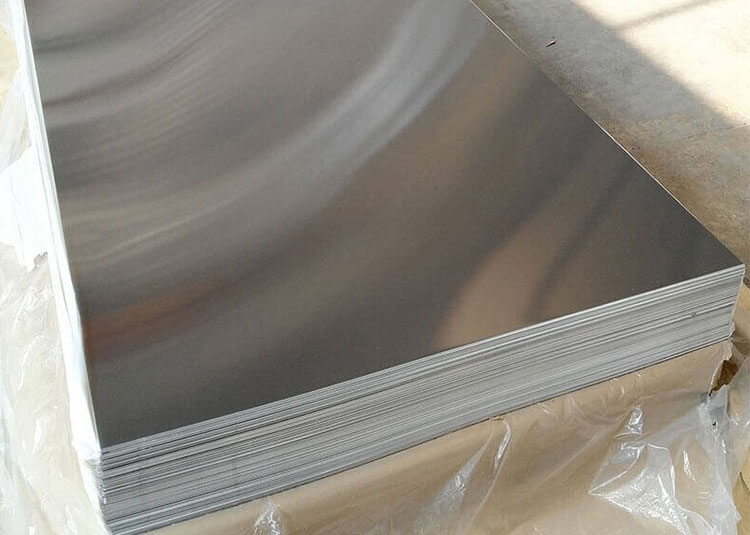

Unique Finishing Touches

Interestingly, the surface finish of aluminum plays a crucial role in the aesthetic and functional domains. These plates naturally produce a protective oxide layer, which, when properly crafted through anodization or painting, can withstand harsh climatic conditions and environmental challenges. Whether in marine vehicles or large public art installations, the defense these plates put forth illustrates their resistance against humidity, salt erosion, and extreme temperature changes—all while eye-catching finishes stimulate scenic allure.