1060 H24 Color Coated Aluminum sheet

The Vibrant Utility of 1060 H24 Color Coated Aluminum Sheets

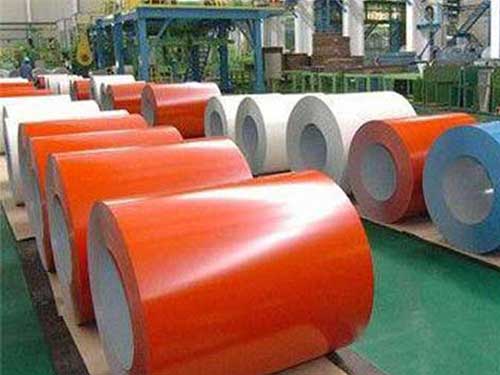

In a world captivated by innovation and elegant design, the material choices we make are pivotal. Among the standout options in the realm of metals, 1060 H24 color coated aluminum sheets emerge as a statement of versatility and vibrancy. These sheets are far more than just a substrate; they embody a fusion of practicality and aesthetics, making them ideal for both industrial applications and decorative projects.

Working with 1060 H24 color-coated aluminum sheet daily, I've come to appreciate its unique properties. The 1060 alloy itself provides excellent formability, making it a dream to work with in our stamping and bending processes. The H24 temper offers a nice balance between strength and ductility; it's robust enough to withstand the rigors of our production line but malleable enough to prevent cracking or fracturing during shaping. The color coating is where things get interesting. We've seen variations in adhesion and durability depending on the specific coating supplier and the pre-treatment process. the nuances of the coating, its resistance to scratching, UV degradation, and corrosion is crucial to delivering a high-quality product that meets our customers' demanding specifications. It's a delicate balance – too much coating and it can crack, too little and the substrate is vulnerable.

Personally, I've seen firsthand the impact of minor variations in our process on the final product. A slight adjustment in the oven temperature during the curing process can subtly alter the color shade or the coating's adhesion strength. Troubleshooting these issues requires careful analysis, often involving microscopic examination of the coating's structure and testing its adhesion properties. This level of detail reinforces the importance of rigorous quality control at every stage of production. It's fascinating to see how seemingly small adjustments can have significant impacts on the final product's performance and aesthetics

Unraveling the Composition: The 1060 H24 Alloy Explained

Before we d

- 1060: Indicates the alloy's purity level, comprised of 99.6% aluminum, making it highly malleable and formable.

- H24: Indicates the tempering condition. The “H” signifies cold working, while “24” reflects a medium strength level with a certain degree of annealing, conducive to suitable strength for various applications.

So, what's the catch with color-coated aluminum sheets? The inclusion of a color finish not only offers aesthetic diversity but also adds weather resistance, further enhancing the material's lifespan and usability in various scenarios.

Features of 1060 H24 Color Coated Aluminum Sheets

-

Aesthetic Variety: The customizability offered by color coatings opens doors to an array of tones and finishes. Whether you’re leaning towards subdued whites, vibrant reds, or deep blues, these sheets can be tailored to fit any design aspirations.

-

Corrosion Resistance: The protective coating is not just for good looks; it forms a safeguard against environmental factors. This makes 1060 H24 sheets resistant to moisture and chemicals, extending their functional life even in harsh conditions.

-

Lightweight and Durable: Aluminum’s inherent lightweight nature paired with the robust strength of H24 tempering crescendos into the ideal toughness-to-weight ratio for construction and manufacturing sectors.

-

Excellent Formability: Malleability ensures that these sheets can easily be bent and shaped without compromising their structural integrity, ideal for applications that require intricate designs or configurations.

-

Sustainability Profile: Aluminum is a recyclable material, and by opting for 1060 H24 color coated sheets, industries can contribute to sustainability efforts while enjoying a great performance-enhancing material.

Applications That Shine Bright

Given their diverse characteristics, 1060 H24 color-coated aluminum sheets are extensively utilized across various industries:

-

Architectural Cladding: Offering an elegant finish and lightweight profile, these sheets are ideal for building facades, awnings, and decorative panels that is know while providing durable protective features.

-

Signage: Their color coating serves as an inviting surface for signage, where visibility and aesthetic appeal are vital. Urban environments benefit greatly from the lasting vibrancy of color-coated signage made of these sheets.

-

Interior Design: Whether it’s in custom cabinetry, wall coverings, or ceiling tiles, 1060 H24 sheets embody utility wrapped in sophisticated design, making them a favorite for modern interiors.

-

Automotive and Transportation: The combination of strength, lightness, and resistance to the elements makes them a sought-after material choice in vehicle manufacturing, from external body panels to protective undercarriages.

-

Consumer Products: From housing appliances to electronics, these coated sheets enhance product appearance while shielding vital components from damage and corrosion.

Why Choose 1060 H24 Color Coated Aluminum Sheets?

Selecting 1060 H24 color coated aluminum sheets for your projects blocks numerous benefits — they are more than just sheets of metal; they bring life, durability, and a touch of sophistication to your endeavors. Whether you’re an architect, designer, manufacturer, or business owner, these sheets offer the promise of flexibility and resilience, with the alluring capability to shine in any project or environment.

In summary, the significant qualities and far-ranging applications of 1060 H24 color coated aluminum sheets come together to underscore its utility as both a functional and decorative material. It stands as an opportunity to create without bounds — all while remaining conscious of practical needs and aesthetic outcomes. Design your next masterpiece with these sheets and let your creativity thrive in color and strength!

https://www.al-alloy.com/a/1060-h24-color-coated-aluminum-sheet.html