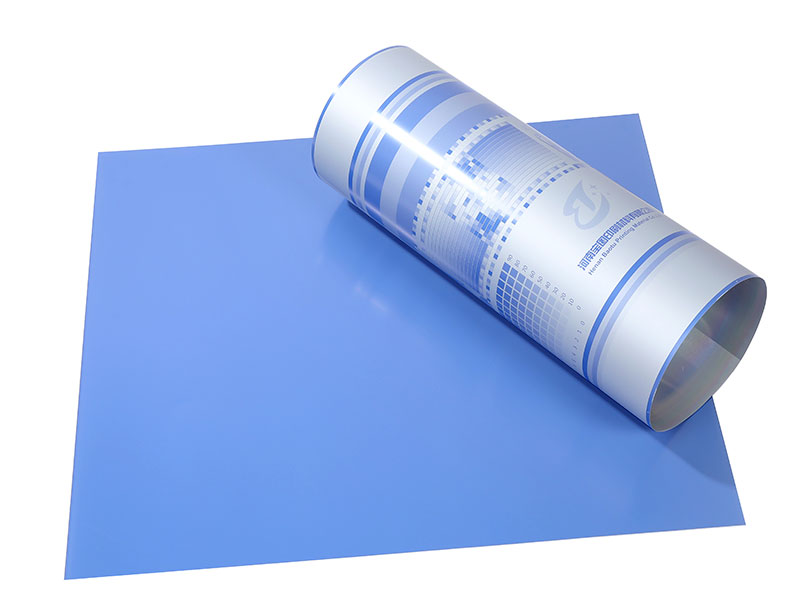

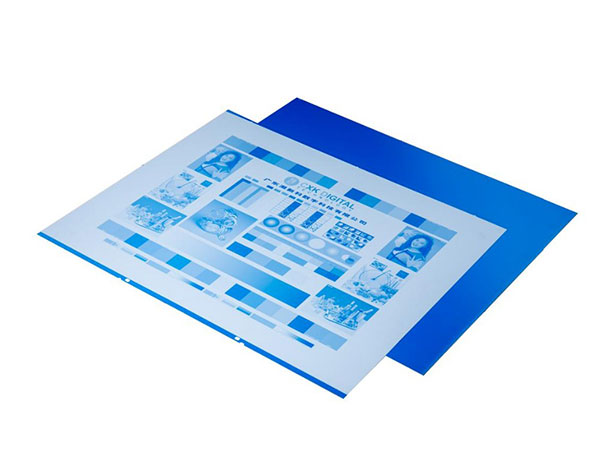

Thermal ctp plate for digital printing

If you've ever picked up a glossy magazine or fascinated the layout of a company brochure, you've encountered the result of an intricate dance between technology and artistry. That perfect print didn't just happen; it was carefully crafted—largely thanks to a sidekick that often goes unnoticed: the thermal CTP (computer-to-plate) plate. Allow me to enlighten you on the role of this surprisingly savvy piece of tech in the realm of digital printing while keeping things easy to digest.

What’s the Deal with Thermal CTP Plates?

First off, l

Working with thermal CTP plates daily, I've noticed a fascinating interplay between chemistry and physics in their performance. The subtle variations in the thermal properties of the aluminum substrate, the precise laser energy needed for exposure, and the subsequent chemical development process all have a significant impact on the final plate quality. A seemingly minor adjustment in the laser power or developer temperature can drastically affect the dot gain, resolution, and ultimately, the print quality. We constantly fine-tune our processes, leveraging data from our quality control systems to identify and minimize inconsistencies. Troubleshooting issues, like plate scumming or poor highlight detail, requires a deep of these interconnected variables – often demanding a blend of practical experience and theoretical knowledge.

Beyond the technical aspects, I see firsthand how the shift towards thermal CTP plates has impacted our factory floor. The transition away from traditional photochemical processes has dramatically reduced our environmental footprint, lowering chemical waste and energy consumption. The improved automation capabilities of thermal systems also mean less manual handling, enhancing both efficiency and worker safety. However, the higher initial investment cost of the thermal equipment presents a challenge. We're constantly evaluating new technologies and plate suppliers to ensure we maintain a competitive edge while balancing cost-effectiveness with environmental responsibility and print quality. The future, I believe, lies in even more efficient and sustainable thermal plate technologies, further reducing waste and increasing print longevity.

Here's the magic: Conventional printing relies on film negatives and chemical processes, which can feel like a throwback in the fast-paced world we live in now. But with thermal plates, lasers gently melt the coating on the plate selectively, translating digital designs into printed language without all that historical fuss. It’s a cleaner, quicker approach that streamlines the aforementioned dance of production while ensuring precision—3 Cheers for innovation!

https://www.al-alloy.com/a/thermal-ctp-plate-for-digital-printing.html