Pharmaceutical Grade Ptp Aluminum Foil

The Unsung Hero of Modern Medicine: Pharmaceutical Grade PTP Aluminum Foil

In the realm of pharmaceutical packaging, an often-overlooked hero plays a foundational role in ensuring medication integrity—pharmaceutical-grade PTP aluminum foil. With its space-age properties and capabilities, this product transcends its simple façade to play a critically important role in global health.

Working with aluminum foil every day, I've come to appreciate the subtle yet crucial differences between grades. Pharmaceutical-grade PTP (Press-Through Packaging) aluminum foil stands out significantly. The purity requirements are far stricter than even our food-grade foil; we're talking about eliminating trace elements that could leach into medication, impacting its efficacy or even posing a health risk. The consistency of the foil's thickness and surface finish is paramount; inconsistencies could lead to improper sealing or even foil perforation, compromising the integrity of the blister pack and potentially contaminating the drug. The entire manufacturing process for this grade is intensely monitored and controlled, with rigorous quality checks at every stage. It's fascinating to see the level of precision involved, a far cry from the more forgiving tolerances we see in other applications.

Beyond the technical specifications, the responsibility that comes with handling pharmaceutical-grade foil is palpable. Knowing that this material is a direct interface with potentially life-saving medication makes the work feel different. A minor flaw, an oversight in our procedures, could have very serious consequences. This contrasts sharply with the relative tolerance for minor variations in, say, our household foil line. The stringent regulations and constant auditing ensure a consistently high standard, but the added pressure to get it right every time is a unique aspect of working with this specialized material. The pride in contributing to a safe and reliable drug delivery system is a significant reward.

What is PTP Aluminum Foil?

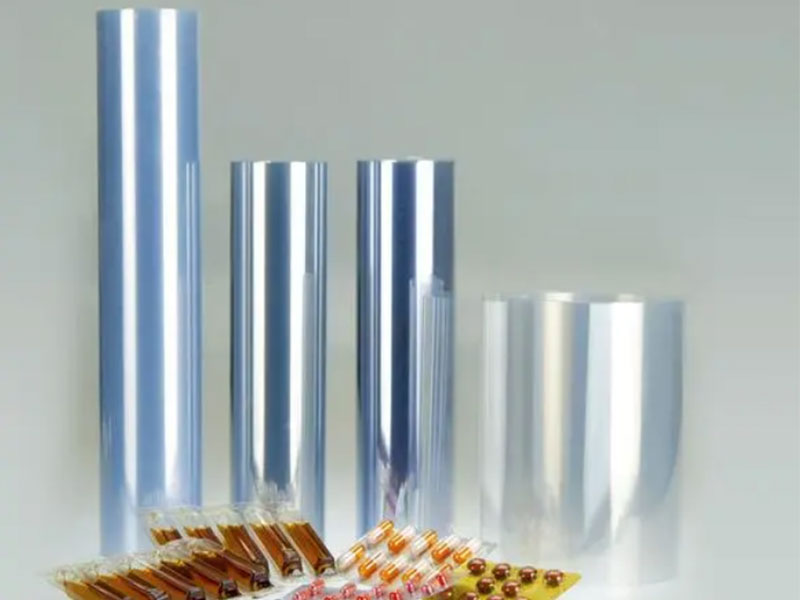

PTP, or "Press Through Pack," aluminum foil is a specialized type of foil used primarily in blister packaging for medications. Its unique capability allows users to easily push the medication out without compromising the rest of the package. Crafted from pharmaceutical-grade alloys, PTP aluminum foil meets stringent requirements mandated by industry standards, ensuring not only quality and safety but also functionality.

Functions: Protecting Integrity and Ensuring Efficacy

The primary challenge in pharmaceutical packaging is balancing protection with user accessibility. Here’s where the multilayer structure of PTP aluminum foil shines:

-

Barrier Properties: Pharmaceutical-grade PTP aluminum foil features exceptional barrier properties against moisture, light, and oxygen. Each of these environmental factors can degrade the efficacy of pharmaceuticals. Light exposure can cause chemical reactions in certain drugs; moisture can lead to premature decomposition, and oxygen can alter the drug's stability. The high barrier properties of this aluminum foil preemptively address these challenges, maintaining the potency and safety of medications.

-

Customization Possibilities: PTP aluminum foil can be engineered with various thicknesses and surface treatments to suit specific pharmaceutical needs. For example, a thicker foil can provide greater protection for sensitive medications, while certain coatings can enhance printability for branding and patient information.

-

Shelf-life Extension: By employing PTP aluminum foil, manufacturers can significantly extend the shelf life of their products. The stability promised by PTP packaging means that both active and inactive ingredients remain in optimal conditions, reducing waste and ensuring consumers receive medications that are effective until expiry.

Applications in Pharmaceutical Industries

Pharmaceutical-grade PTP aluminum foil has revolutionized the packaging landscape as its applications are as diverse as the medications that require them. areas include:

-

Solid Formulations: Blister packaging with PTP aluminum foil is commonly deployed for tablets and capsules, ensuring individual units are kept free from contamination.

-

Controlled Dosage Forms: The controlled dosage capabilities of PTP foils make them ideal for applications ranging from time-release formulations to those requiring precise dosing, offering pharmacies, hospitals, and patients a consistent experience with their medication intake.

-

Response to Global Health Crises: During emergencies like the COVID-19 pandemic, the demand for sterile, high-integrity pharmaceutical packaging spiked. PTP aluminum foil played a crucial role, enabling rapid manufacturing of protective packaging solutions for vaccines, aiding in delivery worldwide under strict conditions.

Environmental Considerations

As healthcare becomes increasingly aware of its environmental impact, manufacturers are leaning toward sustainable production practices. PTP aluminum foils are recyclable, offering hospitals and pharmaceuticals a step toward greener choices. With recycling processes intact, used foils can serve new life, addressing both packaging needs and environmental consciousness.

https://www.al-alloy.com/a/pharmaceutical-grade-ptp-aluminum-foil.html