Features and Applications of Haomei Pharmaceutical PVC Aluminum Foil

Aluminum foil is the only metal material used in packaging, characterized by its non-toxic, odorless, and strong light-blocking properties. When made into blister packaging, it can be easily broken with slight pressure, allowing patients convenient access to their medication and easy portability. The use of pharmaceutical aluminum foil is widespread and well-established, primarily for blister packaging of pharmaceutical capsules, tablets, and for bag packaging of powders, granules, and liquids.

Characteristics of Pharmaceutical Aluminum Foil

Good Moisture Resistance: Pharmaceutical aluminum foil has excellent moisture resistance, effectively preventing drugs from moisture, oxidation, and deterioration.

Strong Barrier Properties: Pharmaceutical aluminum foil features strong barrier properties that effectively block light, oxygen, odors, and microorganisms, protecting the quality of the medication.

Good Heat Sealing Performance: Pharmaceutical aluminum foil has good heat sealing properties, allowing for the sealing of drug packaging through heat sealing processes, preventing oxidation, deterioration, and contamination of the medication.

Strong Processability: Pharmaceutical aluminum foil can be enhanced through processes like lamination and coating to meet the packaging needs of different medications.

Safety and Hygiene: Pharmaceutical aluminum foil is a non-toxic, odorless packaging material free from harmful substances, complying with hygiene requirements for pharmaceuticals.

As a packaging material for pharmaceuticals, aluminum foil offers advantages such as moisture resistance, barrier properties, heat sealing, good processability, and safety and hygiene, making it a commonly used material in drug packaging.

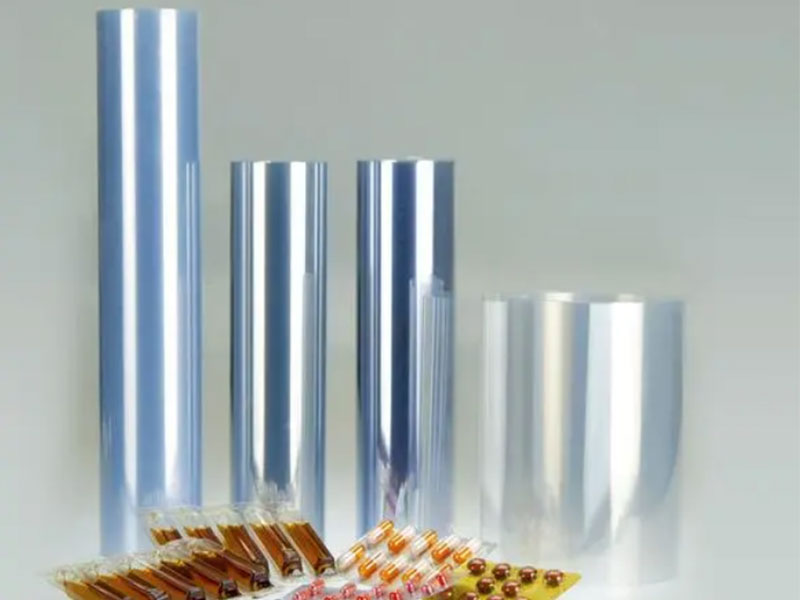

Characteristics and Advantages of PVC Aluminum Foil

Excellent Physical Properties: PVC material exhibits good abrasion resistance, tear resistance, compressive strength, and impact resistance, effectively protecting medications from external environmental influences.

Strong Chemical Stability: PVC material has good acid and alkali resistance, oxidation resistance, and corrosion resistance, protecting medications from chemical substances.

Ease of Processing and Molding: PVC material has good plasticity and processability, facilitating various processing and molding to create drug packaging in different shapes and specifications.

Cost-Effective: PVC material is relatively low-cost, helping to reduce manufacturing costs for drug packaging.

High Surface Gloss: Pharmaceutical PVC aluminum foil has high transparency and good surface gloss, suitable for high-precision printing.

Strong Chemical Resistance: Suitable for cytotoxicity and nuclear medicine, it is appropriate for long-term contact with human tissues.

Applications

Blister Packaging: Blister packaging made from PVC material effectively protects medications from external environmental influences while allowing for easy observation of the medication's color and shape.

Pharmaceutical Bottle Labels: Labels made from PVC material can print information such as the drug name, usage, dosage, production date, and expiration date, facilitating user management of medications.

Sealing Components: Sealing components made from PVC material effectively protect medications from external environmental influences while maintaining the sealing and stability of the drugs.

Haomei Aluminum has newly built five production lines for PVC/PVDC composite foil and pharmaceutical aluminum foil, with products exported to countries such as Ecuador, Mexico, Spain, South Korea, the United States, New Zealand, and Canada.

https://www.al-alloy.com/a/features-and-applications-of-haomei-pharmaceutical-pvc-aluminum-foil.html