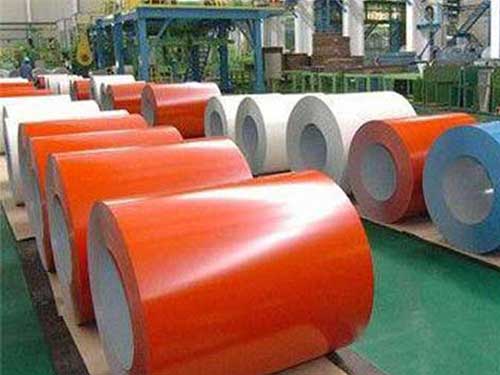

Pvdf Coating Color Coated Aluminum Coils

In the world of modern construction and manufacturing, the choice of materials can greatly influence the durability, aesthetics, and overall performance of a project. Among the various materials available, PVDF coating color coated aluminum coils have emerged as a leading choice for architects, builders, and manufacturers alike.

What is PVDF Coating?

PVDF stands for Polyvinylidene Fluoride, a high-performance material known for its exceptional resilience and environmental resistance. When applied as a coating on aluminum coils, it forms a durable and long-lasting surface that can withstand harsh weather conditions, UV radiation, and chemical exposure. This makes PVDF coating an ideal choice for both exterior and interior applications.

Key Advantages of PVDF Coating Color Coated Aluminum Coils

1. Exceptional Durability

One of the standout features of PVDF coating is its unparalleled durability. It retains its color and gloss for extended periods, significantly outperforming other coatings under tough environmental conditions. This property ensures that buildings maintain their aesthetic appeal over time, reducing the need for maintenance and repainting.

2. Energy Efficiency

PVDF coated aluminum coils can be designed to reflect solar radiation, making them highly energy-efficient. This capability is particularly beneficial in commercial buildings, where reducing energy consumption is paramount. By reflecting heat, these coils can help lower cooling costs in warmer climates.

3. Aesthetic Varieties

Available in a myriad of colors and finishes, PVDF coating allows architects and designers to unleash their creativity and cater to specific aesthetic requirements. From metallic finishes to vibrant hues, the versatility in color options enables seamless integration with various architectural styles.

4. Environmentally Friendly

With an increasing focus on sustainability in the construction industry, PVDF coated aluminum coils present a more environmentally friendly option. The materials used in these coatings are often recyclable, and the energy efficiency they provide contributes to lower carbon footprints.

5. Corrosion Resistance

Aluminum naturally provides a degree of corrosion resistance, but when coated with PVDF, this resistance is enhanced significantly. This property makes PVDF coated coils an excellent choice for coastal areas or industrial settings where exposure to chemicals and saltwater can lead to faster degradation.

Applications of PVDF Coating Color Coated Aluminum Coils

PVDF coated aluminum coils are incredibly versatile and can be utilized in a range of applications, including:

- Building Facades: Their robustness and aesthetic appeal make them perfect for cladding, curtain walls, and other architectural elements.

- Interior Design: Due to their variety in colors and finishes, these coils can be used in ceilings, partitions, and decorative features.

- Signage: The long-lasting colors and resistance to fading make these coils ideal for outdoor signage.

- Manufacturing and Appliances: They are also used in manufacturing other products, from appliances to automotive parts where both form and function are critical.

https://www.al-alloy.com/a/pvdf-coating-color-coated-aluminum-coils.html