Aluminum Coil for CTP UV Plates and cei

In the world of modern printing technology, the demand for high-quality, durable, and cost-effective solutions has never been greater. Among the innovations driving this industry are aluminum coils specifically designed for Computer-to-Plate (CTP) ultraviolet (UV) plates and Consumer Electronics Interface (CEI) applications.

Features of Aluminum Coil for CTP UV Plates

1. Lightweight yet Robust

Aluminum’s innate properties make it an ideal choice for printing applications. With a lower density compared to other metals, aluminum coils are remarkably lightweight, which simplifies material handling and reduces shipping costs. Despite this, aluminum retains strength and rigidity, allowing it to support demanding tasks without compromising performance.

The quality of the aluminum coil is paramount in producing high-quality Aluminium CTP plates. We've found that even subtle variations in alloy composition, grain size, and surface finish significantly impact the final product's performance. For instance, inconsistencies in the coil's surface can lead to uneven plate thickness, resulting in poor image reproduction and increased plate degradation during printing. Similarly, impurities within the aluminum can cause pitting or corrosion, leading to plate rejection and wasted resources. Therefore, rigorous incoming inspection of the coil, focusing on these critical parameters beyond just the standard thickness and width specifications, is essential to maintain consistent production quality and minimize scrap.

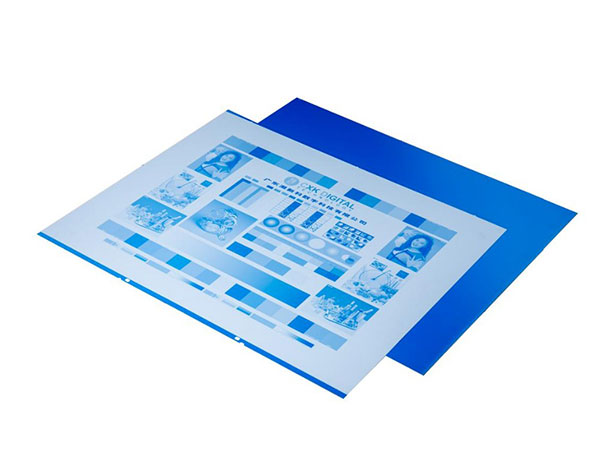

Beyond the initial coil characteristics, the processing steps applied to the aluminum before plate manufacturing are crucial. The cleaning and anodizing processes, for example, must be precisely controlled to ensure optimal adhesion of the photosensitive layer. We've seen cases where subtle variations in these processes, even within the acceptable ranges, lead to significant differences in the final plate's sensitivity, resolution, and overall durability. This highlights the need for continuous monitoring and fine-tuning of these processes, along with meticulous data logging, to proactively identify and address potential issues before they impact large production runs, ultimately saving time, money and improving the yield of high-quality CTP plates.

2. Exceptional Precision

Precision is essential in the world of printing — even the slightest imperfection can affect the quality of the final product. Aluminum coils boast exceptional dimensional accuracy, ensuring uniformity in thickness and surface finish. This quality is particularly critical in CTP applications, where the imaging process relies on the precision of the plate’s surface to render detailed graphics and text sharply.

3. Superior Thermal Conductivity

One of the defining characteristics of aluminum is its ability to conduct heat effectively. This property is pivotal when UV plates are subjected to certain thermal configurations during the printing process. Proper heat distribution prevents warping and guarantees that the imaging solutions adhere consistently, ultimately contributing to optimal printing quality and reduced waste.

4. Corrosion Resistance

Aluminum demonstrates resistance to weathering and corrosion. This quality preserves the longevity of UV plates and enhances their performance in various working environments. For printers, it means less downtime and reduced maintenance costs, effectively translating to improved operational efficiency.

Applications of Aluminum Coil in CTP UV Plates and CEI

1. Printing Industry

Aluminum coils are a cornerstone of the printing sector, specifically for CTP applications involving UV plates. With their superior adhesion properties and extraordinary accuracy, these coils facilitate high-resolution imaging, enabling printers to produce vibrant, detailed pages with enhanced durability. CTP technology minimizes manual touches, leading to streamlined production workflows and significant cost savings.

2. Consumer Electronics Interface (CEI)

In addition to traditional printing applications, aluminum coils are gaining traction within the realm of CEI devices. Their lightweight and thermal conductive attributes make them perfect candidates for heat sinks, facilitating efficient heat dissipation in electronic devices. As technology continues to shrink in size but grow ever more powerful, aluminum's role in thermal management and structural support is poised to become more prominent.

3. Eco-Friendliness and Recyclability

Above all, aluminum is known for its recyclability. Manufacturers often target eco-friendly practices within their production processes, and using aluminum coils aligns seamlessly with these values. For CTP UV plates, this ecological benefit resonates well with companies striving for sustainability, allowing for responsible disposal while producing high-quality outputs.

4. Customization

The inherent versatility of aluminum allows for a wide array of customization options. Producers can modulate thickness, surface finish, and coating types tailored to specific needs in precision printing applications or advanced electronic architectures. This flexibility supports innovation while helping manufacturers stay competitive in a rapidly evolving market.

https://www.al-alloy.com/a/aluminum-coil-for-ctp-uv-plates-and-cei.html