Aluminum aluminium plate panels

Aluminum plate panels are emerging as a go-to material in numerous industrial and commercial sectors, well-noted for their incredible versatility, strength, and lightweight properties.

Aluminum Plate Panels

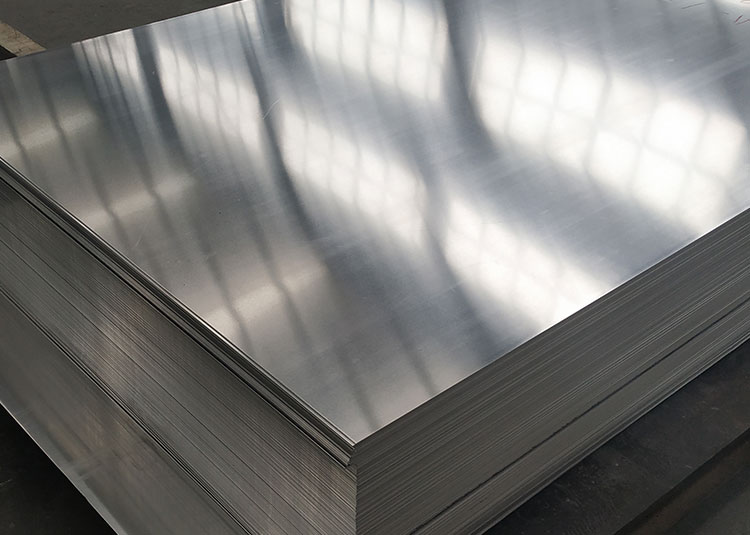

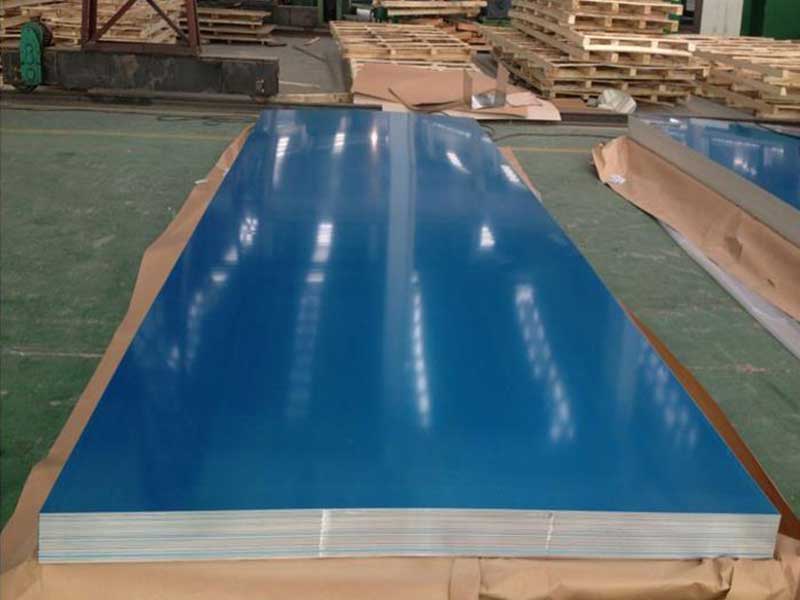

Before diving into specifics, it's essential to depict what aluminum plate panels actually are. These panels are made from a range of aluminum alloy grades, often within the 1000 to 7000 series, based on the required strength and corrosion resistance characteristics. With thicknesses typically varying from 0.5 mm to over 25 mm, they are custom-manufactured for diverse applications in architecture, manufacturing, automotive, and more.

From my perspective on the factory floor, "aluminum plate panels" – as we often call them – are far more than just flat sheets of metal. We see the raw material arrive, thick coils of aluminum, and then witness its transformation through a series of intricate processes. The precision involved in rolling, annealing, and sometimes even surface treating is incredible. A tiny imperfection in any stage can ruin an entire batch, highlighting the need for constant vigilance and meticulous attention to detail. It's satisfying to see a finished panel, knowing the countless hours and precise calibrations that went into its creation – a testament to both human skill and powerful machinery. The variations in thickness, finish (from brushed to mirror polished), and alloy composition are also fascinating; each panel tells a story of specific customer needs and the factory's ability to meet them.

Beyond the technical aspects, I've noticed a certain emotional connection develop with the product. We know the potential of these panels – from their use in high-end architectural facades shimmering under the sun, to their role in industrial applications requiring strength and corrosion resistance. There's a quiet pride in seeing our finished goods shipped out, knowing they'll contribute to diverse and important projects worldwide. It's more than just a job; it's participating in a process that shapes the built environment and helps drive innovation in numerous industries. The hum of the machinery, the precise movements of the rollers, the satisfying weight of a

Features and Technical Details

-

Lightweight Nature: One of the most compelling advantages is the minimalist weight of aluminum compared to other metals like steel. This feature not only enhances ease of handling but also results in lower transportation costs, particularly crucial in automotive and aerospace applications.

-

Strength-to-Weight Ratio: Aluminum’s specific strength is unrivaled. This robust strength, combined with its lightweight nature, means that aluminum plate panels can withstand significant stress without compromising structural integrity. They possess an ultimate tensile strength (UTS) standing around 60,000 to 75,000 psi, a crucial parameter for heavy-duty applications.

-

Corrosion Resistance: Naturally occurring aluminum oxide provides an excellent layer of protection against corrosion, which is indispensable for structures exposed to the elements, such as bridges or buildings near coastal areas.

-

Thermal and Electrical Conductivity: As one of the best materials for efficient thermal management, aluminum plate maximizes heat dissipation, making them suitable for applications involving heat exchangers and electrical connections where minimizing lost energy is vital.

Functions of Aluminum Plate Panels

The functionality of aluminum plate panels goes beyond merely acting as a structural component. Here are some notable functions:

-

Aesthetic Appeal in Architecture: Used extensively in modern architectural exteriors, aluminum plate panels enhance building façades and ceilings thanks to their sleek appearance and ability to be coated in various finishes.

-

Radiant Energy Management: Due to aluminum's excellent thermal properties, plates can effectively manage heat, crucial in designing more efficient HVAC systems and solar panels.

-

Sound Insulation and Absorption: When applied as interior wall panels, aluminum helps reduce sound transmission, creating quieter environments necessary in gymnasiums or offices.

Diverse Applications of Aluminum Plate Panels

-

Construction: Aluminum plate panels are integral in constructing façades, roofs, partitions, fire shutters, and support structures. They offer rapid installation processes while fostering energy efficiency and sustainability.

-

Transport and Aerospace: The automotive and aerospace industries rely heavily on aluminum for its weight-saving attributes, which improve fuel efficiency in vehicles and aircraft alike. Components like fuselages, wings, and body panels often consist of aluminum plates.

-

Marine Medium: Used in boat manufacturing and modifications, the strong yet lightweight character of aluminum allows for improved performance on water while resisting corrosive conditions present in marine environments.

-

Artwork & Signage: Fabricators design stunning artwork and large-format graphics using aluminum plate panels for capabilities like CNC machining and laser cutting. Financial signage and monuments also take advantage of its structural fortitude without added weight.

Innovations and Future Directions

The ongoing exploration into aluminum alloys continues to foster innovation. Advances in alloying technologies have unlocked complexities such as even greater corrosion resistance and faster fabrication timelines. Moreover, developments in surface treatments can enhance the aesthetic options tenfold from brushed to polished to powder-coated panels, aiding the compression of delicate designs within structures.

https://www.al-alloy.com/a/aluminum-aluminium-plate-panels.html