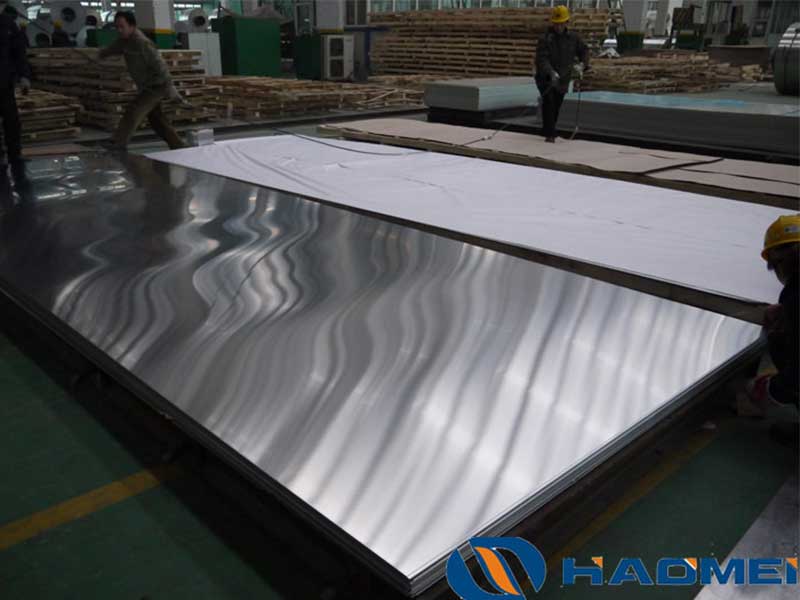

6063 T6 Aluminum Sheet 1mm Thick

In the world of materials engineering and construction, aluminum alloys remain a prime choice due to their unique properties and versatility. Among the many types available, the 6063 T6 aluminum sheet, particularly in a 1mm thick dimension, stands out for its remarkable characteristics and diverse applications. In this article, we will explore what sets the 6063 T6 alloy apart and how its features synergize with numerous uses.

Overview of 6063 T6 Aluminum Alloy

6063 is a medium-strength aluminum alloy that contains magnesium and silicon as its principal alloying elements. When tempered to T6 form, this alloy exhibits increased mechanical strength and outstanding corrosion resistance. The combination makes the 6063 T6 aluminum sheet particularly suitable for fabrication and structural applications, especially where aesthetic quality and durability are concerned.

Features of 6063 T6 Aluminum Sheet 1mm Thick

-

Exceptional Workability: One of the key attributes of the 6063 alloy is its excellent extrudability and machinability. This property enables manufacturers to customize the sheet into various shapes while maintaining structural integrity, making 1mm sheets easy to work with.

-

Lightweight: Aluminum is known for its lightweight nature, and the thickness of 1mm enhances this characteristic. This lightweight aspect is crucial in reducing shipping and handling costs across various industries.

-

Corrosion Resistance: The naturally occurring oxide layer on aluminum provides substantial protection against corrosion. The T6 temper enhances this feature, ensuring that the aluminum sheet can withstand outdoor conditions, ensuring long life and low maintenance costs.

-

Aesthetic Appeal: Sheets fashioned from 6063 T6 aluminum can also possess an appealing smooth finish. This aesthetic quality, combined with excellent paint adhesion, makes it an ideal option for applications requiring a visually pleasing surface.

-

Thermal Conductivity: Aluminum is a good conductor of heat, a factor that becomes remarkably beneficial in various technical applications where temperature regulation is crucial.

-

Recyclability: With increasing concerns about environmental sustainability, 6063 T6 aluminum sheets offer a recyclable material option. This feature adds to their appeal in a world increasingly focused on eco-friendly practices.

Applications of 6063 T6 Aluminum Sheet 1mm Thick

The features provided by 6063 T6 aluminum sheets make them highly versatile, leading to their use in numerous sectors.

1. Architectural Applications

6063 T6 aluminum sheets are extensively utilized in the architectural industry, particularly in building facades, window frames, doors, and roofing. Their lightweight behavior complemented by excellent corrosion resistance makes them perfect for high-rise structures and commercial buildings requiring both durability and style.

2. Automotive Industry

In the automotive sector, weight reduction is pivotal for improving fuel efficiency and driving dynamics. The 1mm thick 6063 T6 aluminum sheets are engaged in components like interior panels, body trims, and assemblies due to their reduced mass and strong structural integrity.

3. Transportation

Beyond automobiles, these aluminum sheets are frequently used in the manufacturing of transport containers, trailers, and aesthetic components across the transportation industry, ensuring reduced weights and improved fuel economy.

4. Electrical Components

Given its excellent thermal conductivity, 6063 T6 aluminum sheet is also employed in the manufacturing of various electrical parts and fixtures. Their lightweight property ensures easier assembly and better performance in electrical applications.

5. Furniture Design

Given their strength and attractive finish, 6063 T6 aluminum sheets are increasingly favored in the modern furniture design sector, providing sturdy yet stylish solutions for tables, brackets, and displays.

https://www.al-alloy.com/a/6063-t6-aluminum-sheet-1mm-thick.html