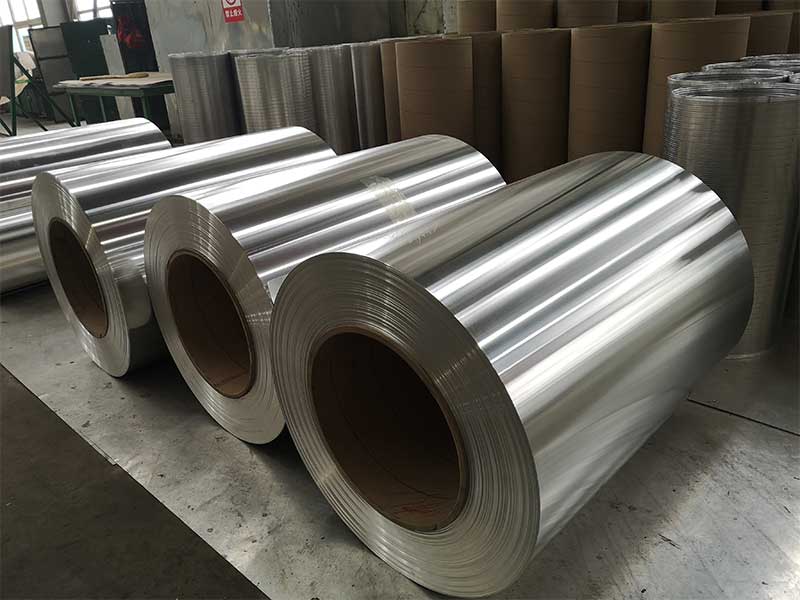

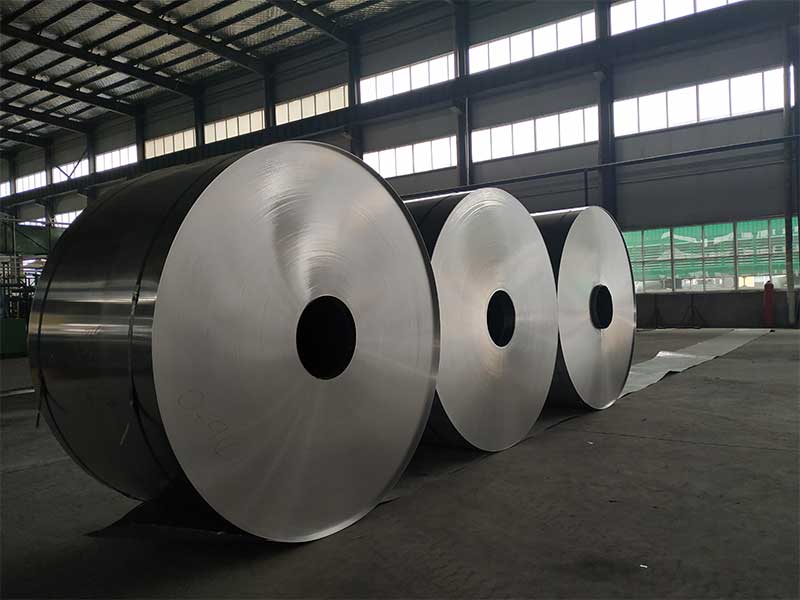

1.0mm Thickness Pre Painting Aluminum Coil

In today's fast-paced industrial landscape, material choice plays a critical role in determining the performance, longevity, and aesthetic appeal of projects across multiple sectors. Among the leading contenders surrounded by innovative thinking is the 1.0mm thickness pre-painted aluminum coil. This versatile material consists of solid aluminum substrates coated in layers of protective paint, leaving proponents asking: what can it truly achieve?

Technical Specifications Elevated Manufacturing Precision

Before its applications, let's dive into the technical nuances of the 1.0mm thickness pre-painted aluminum coil. Manufacturing this product consists of precision engineering and state-of-the-art painting techniques. The aluminum base typically comprises alloys like 3003 and 5251, which strike an impeccable balance between operability and formability. Additionally, its 1.0mm thickness ensures not only durability but also flexibility, making it advantageous for various shapes and sizes during fabrication projects.

1.0mm thickness pre-painted aluminum coil presents a unique set of challenges compared to thicker gauges. Its thinner profile makes it more susceptible to scratching and denting during handling and processing, demanding meticulous care throughout the production line. We've found that optimizing coil tension during unwinding and rewinding is crucial to prevent surface imperfections. Furthermore, the pre-painting process itself requires precise control of coating thickness and adhesion to ensure durability and prevent delamination, especially given the flexibility of the thinner material. Slight inconsistencies in the paint application can become significantly more noticeable on a 1.0mm coil than on a thicker one, impacting the final product's aesthetic quality and potentially leading to higher rejection rates.

Another consideration is the specific application for this coil. While suitable for a range of uses, its thinner gauge might limit its suitability for applications requiring high structural strength or resistance to significant impact. We've seen increased demand for this thickness in industries prioritizing lightweight construction, such as automotive parts or building cladding. However, rigorous quality control is essential, especially in testing for paint adhesion and resistance to bending and flexing, to ensure the coil meets the specified requirements of the end-user. the specific end-use allows for tailored quality checks and production adjustments to minimize waste and maximize customer satisfaction.

Its pre-painting precursors tune into the current trends in color technology. The application of high-performance paint results in significant UV resistance, excellent durability against unexpected weather conditions, and a magnificent surface finish that does not fade or degrade over time. Notably, two essential applications for these paints are silicone-modified polyester and high-durability PVDF formulations, which ensure surface robustness versatile enough to withstand prolonged environmental stresses.

Functions at a Glance

What powers the efficiency of pre-painted aluminum coils is their multifunctionality in various industrial realms, primarily envelopes dealing with construction, transportation, signage, and even consumer goods.

-

Architectural Applications: The glistening touch of aesthetic finish enabled by the pre-paint process elevates the architectural appeal of modern buildings. Whether for curtains wall systems, roofing sheets, facades, suspensions, or ceilings, the relatively lightweight properties and robustness of the aluminum guarantee spatial practicality combined with a captivating design, impervious to environmental deterioration. With endless designs and colors available, aesthetic alignment with contemporary architectural elements is swiftly established.

-

Transportation Sector: In the automobile industry, especially for strong decorative profiles and exposed structurals, the 1.0mm app combines elegance, weight-saving potential, and flame-resistant properties. The typical environments to which aluminum deals range from leading vehicle exteriors to trailing truck cover components, each thereby benefiting from the shallow weight distribution; thus optimizing fuel scores sans sacrificing performance.

-

Signage Sturdiness: When establishing brand visibility, various structures like billboards and light boxes capitalize on pre-painted aluminum coils due to their resilient characteristics. It allows brands to express graphical completeness while keeping manufacturing upkeep minimal, given that such backgrounds resist stains, impacts, and general fuss in relation to weather fluctuations.

-

Consumer Goods: Manufacturers producing other limited-run products such as home décor pieces makes use of the endurance reflecting that distinguished coating once again proves critical in both form and delivery.

https://www.al-alloy.com/a/10mm-thickness-pre-painting-aluminum-coil.html