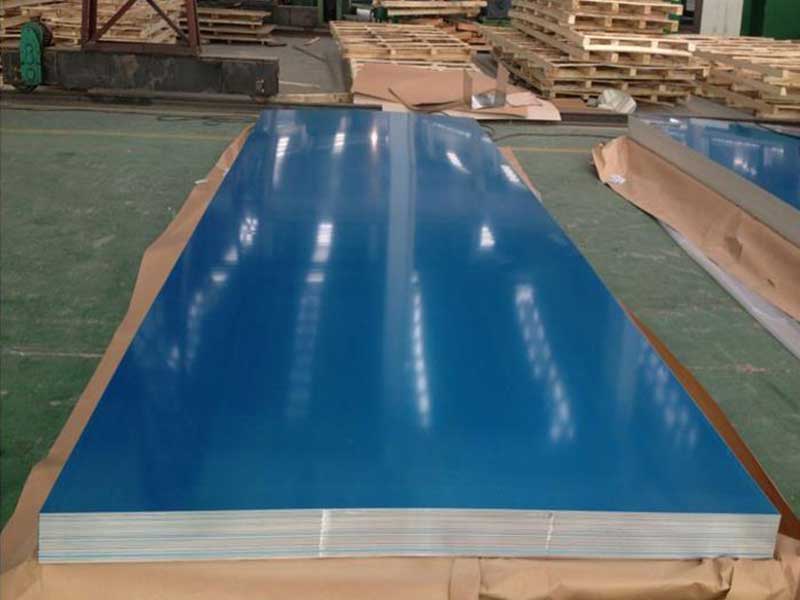

Stamped aluminum sheet

Introduction to Stamped Aluminum Sheets

Aluminum is recognized for its lightweight and versatile characteristics, making it a preferred material in numerous industrial applications. Among its myriad forms, stamped aluminum sheets stand out as a practical solution for various industries.

What are Stamped Aluminum Sheets?

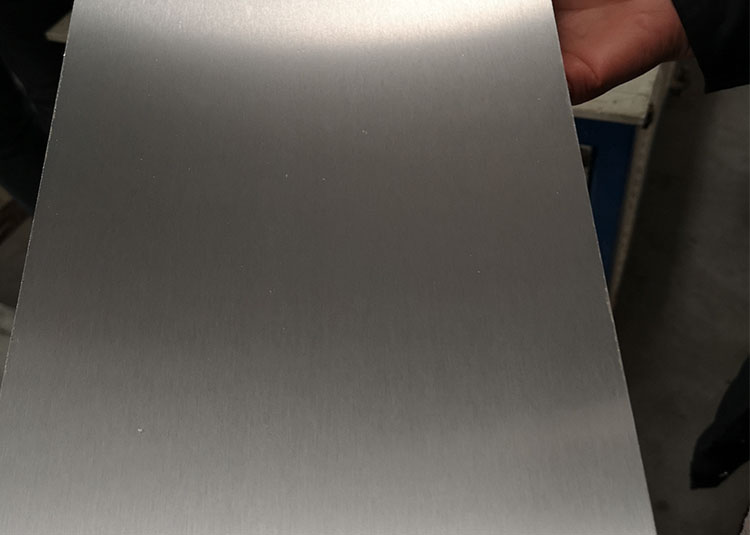

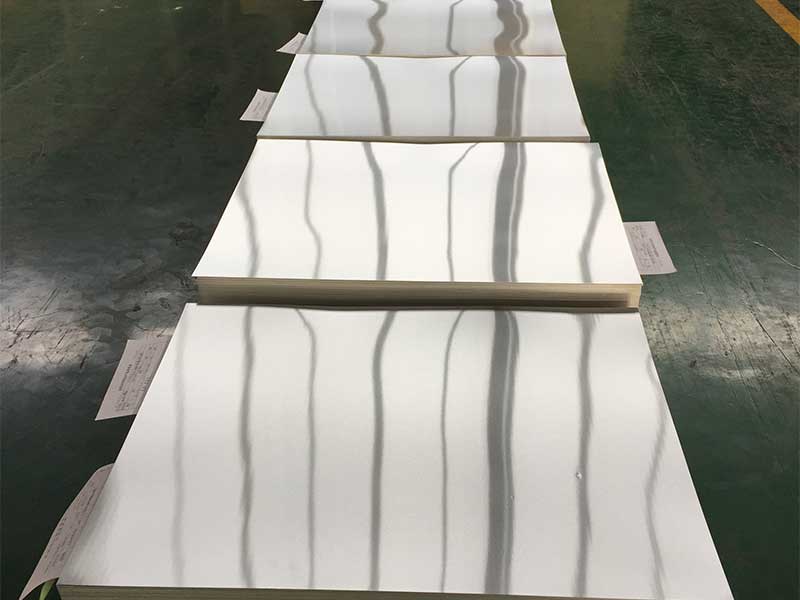

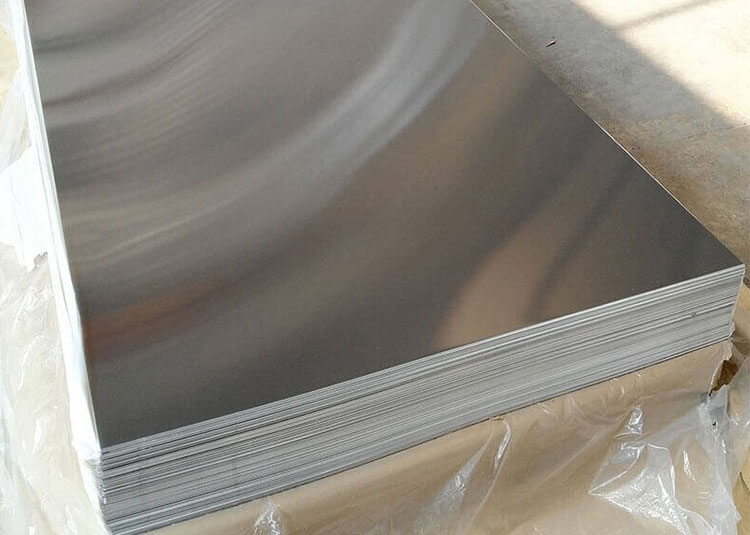

Stamped aluminum sheets undergo a manufacturing process where sheets of aluminum are cut and shaped using dies and a stamping press. This process allows for intricate designs and maintaining tight tolerances, making them ideal for producing complex parts with precise specifications. The stamping operation results in an extensive variety of shapes, patterns, and finishes, expanding the potential uses of aluminum sheets dramatically.

Benefits of Stamped Aluminum Sheets

1. Lightweight Construction One of the standout features of stamped aluminum sheets is their lightweight nature. This attribute is especially crucial in industries such as automotive and aerospace, where reducing weight translates to fuel savings and improved efficiency.

2. Strength and Durability Despite their light weight, stamped aluminum sheets are remarkably sturdy. Aluminum itself provides excellent resistance to corrosion and weathering, which makes these sheets ideal for both indoor and outdoor applications.

3. Customization Options With advancements in stamping technology, manufacturers can customize aluminum sheets to meet individual specifications. From varying thicknesses to unique patterns and finishes, customers can create solutions tailored to their specific needs.

4. Cost-Effectiveness Due to efficient manufacturing techniques, utilizing stamped aluminum sheets can be a cost-effective option for large-scale production. Reduced material waste and minimized handling contribute to overall savings.

Applications of Stamped Aluminum Sheets

The applications of stamped aluminum sheets are extensive, making them suitable for diverse sectors:

- Automotive Industry: stamped aluminum sheets play a significant role in vehicle body components, targeting weight reduction without sacrificing safety.

- Aerospace: Used in components such as fuselage panels, stamped aluminum assists in meeting strict weight requirements essential for aircraft.

- Architecture and Construction: From decorative ceiling panels to durable wall coverings, the design possibilities improve aesthetic appeal while maintaining performance integrity.

- Electronics: Embedded in cases and housings, stamped aluminum sheets enhance the functionality of various electronic devices, offering both electromagnetic shielding and heat dissipation.

- HVAC Applications: Stamped aluminum sheets are frequently used in HVAC ducting, providing excellent thermal efficiency and ease of installation.