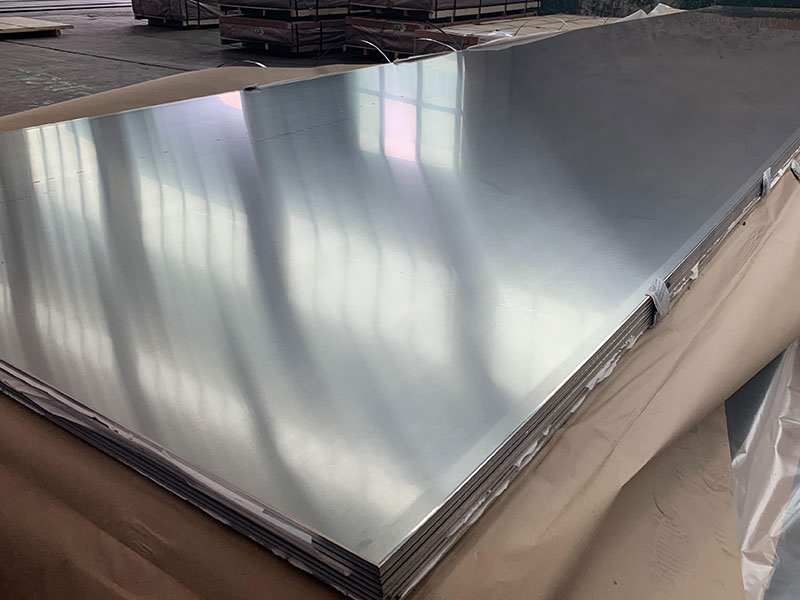

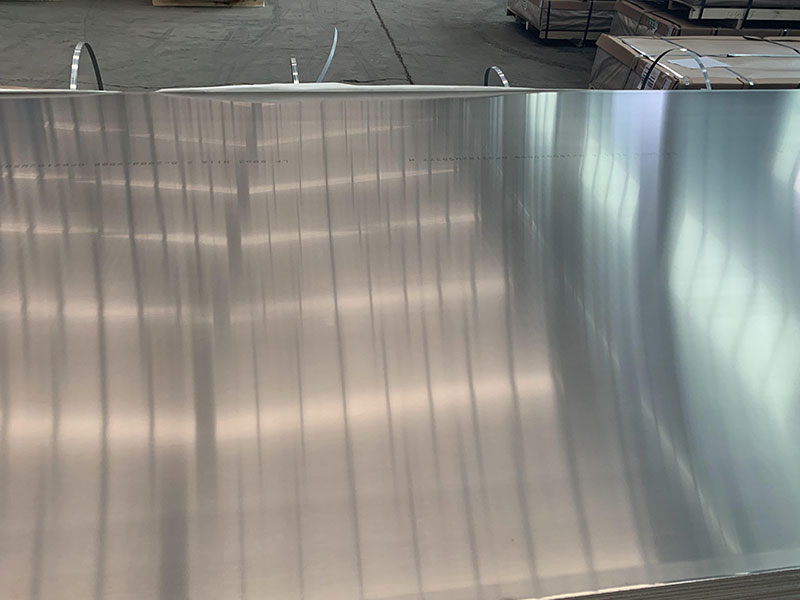

Marine grade aluminium alloy sheet

Unveiling the Benefits and Applications of Marine Grade Aluminum Alloy Sheets

When it comes to materials that can withstand the rigors of the marine environment, marine grade aluminum alloy sheets is know as the premium choice. Engineered specifically to combat saltwater corrosion and to deliver excellent mechanical performance, these sheets are frequently utilized across various coastal and maritime applications.

What is Marine Grade Aluminum Alloy?

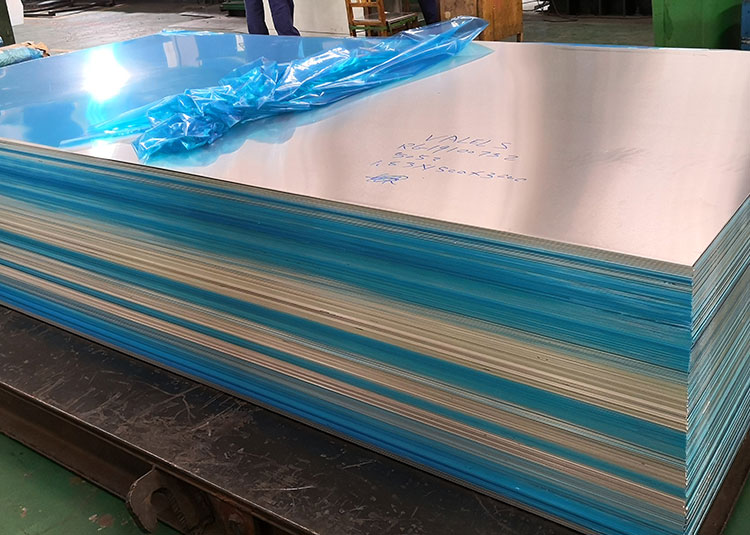

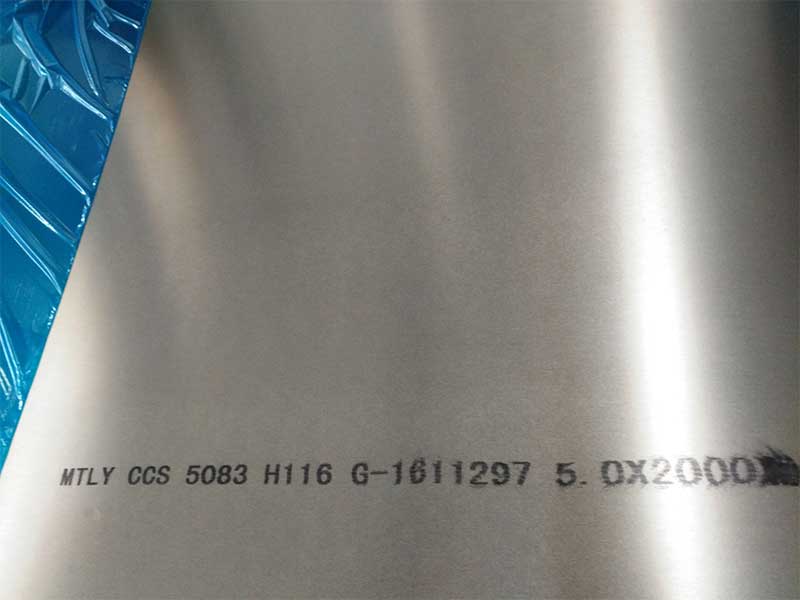

Marine grade aluminum alloys are specifically designed to resist corrosion caused by seawater, making them a superior choice for boatbuilding, ships, and coastal infrastructure. The most common alloys used include 5083 and 5052, noted for their outstanding workability, strength, and resistance to seawater. These alloys often contain magnesium as a main alloy element, helping to improve corrosion resistance and broadening their application spectrum without compromising on structural integrity.

Features of Marine Grade Aluminum Alloy Sheets

-

Corrosion Resistance: One of the foremost features of marine grade aluminum alloy sheets is their exceptional corrosion resistance. The special magnesium and other alloying elements react with seawater, forming a protective oxide layer that prevents rust and degradation over time.

-

Strength-to-Weight Ratio: Marine grade aluminum offers incredible strength without the heavy weight of traditional metals such as steel. This lightweight nature enhances performance, particularly in structures requiring high durability with minimal additional weight ballast.

-

Weldability: These aluminum alloys exhibit excellent welding properties, making them highly adjustable and applicable to various manufacturing techniques. This feature allows for flexibility in design and fostering innovative marine solutions.

-

Thermal Conductivity: Marine grade aluminum alloy sheets demonstrate good thermal conductivity as well, allowing heat generated by sun exposure and other elements to dissipate efficiently.

-

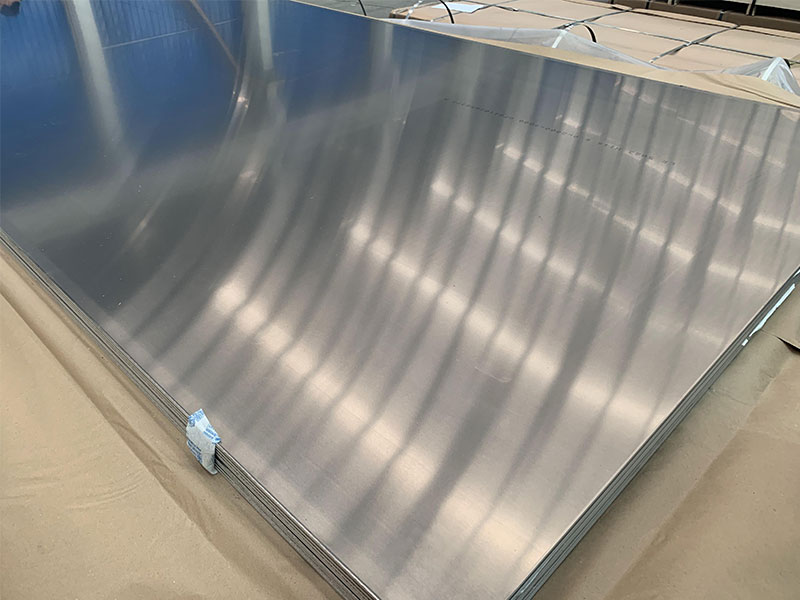

Aesthetic Appeal: In addition to their functionality, aluminum sheets provide a polished and sleek finish. This physical trait makes them a desirable option not just for their utility, but also for visual aesthetics in vessels.

Applications of Marine Grade Aluminum Alloy Sheets

1. Boat and Ship Building

Perhaps the most recognized application of marine grade aluminum alloy sheets is in the boat and shipbuilding industry. Manufacturers utilize these sheets for hull construction, internal structures, and deck components, where durability against saltwater is paramount.

2. Oil and Gas Platforms

Aluminum sheets are widely applied in constructing offshore platforms and other maritime structures that require long-term exposure to harsh conditions. Their resistance to corrosion and light weight eases transport and installation, ensuring ideal operational functionality on the open water.

3. Coastal Infrastructure

From bridges connecting islands to structural components of harbors and shipyards, marine grade aluminum alloy sheets play a vital role in strong and resilient coastal infrastructure. Their durability ensures safety and prolongs lifespan, even in extreme weather conditions.

4. Recreational Vehicles and Equipment

In the recreational boating sector, these aluminum sheets are used in manufacturing yachts, fishing boats, and personal watercraft. Enthusiasts appreciate their durability and lightweight nature as they contribute to enhanced vessel performance and fuel efficiency.

5. Aerospace and Automotive Industries

More recently, there is burgeoning interest in using marine grade aluminum alloy sheets in aviation and automotive sectors, particularly in designing lighter weight and corrosion-resistant components within a maritime context.

https://www.al-alloy.com/a/marine-grade-aluminium-alloy-sheet.html