H12 h22 h14 h24 temper mirror finish embossed aluminum sheet

In the realm of modern materials, aluminum holds a significant position due to its unique blend of lightweight strength, durability, and versatility. Among the aluminum products available today, the H12, H22, H14, and H24 temper mirror finish embossed aluminum sheets stand out. Featuring various temper classifications, these sheets are tailored for a diverse range of industrial applications, each bringing distinctive characteristics that enhance functionality and aesthetics.

What Are Temper Designs?

Temper designations like H12, H22, H14, and H24 refer to various stages within the aluminum processing cycle, indicating how the material was treated post-extrusion. Each temper affects the strength, formability, and representative characteristics of the aluminum:

- H12: Represents work-hardened and partially annealed aluminum, ideal for applications needing some strength without a full heat treatment.

- H22: Indicates a higher degree of work hardening which enhances surface hardness while retaining good formability.

- H14: This is a strain-hardened temper characterized by superior strength-to-weight ratio and stiffness.

- H24: Involves strain hardening followed by annealing, promoting stress relief and improving ductility without sacrificing strength.

Exceptional Features

-

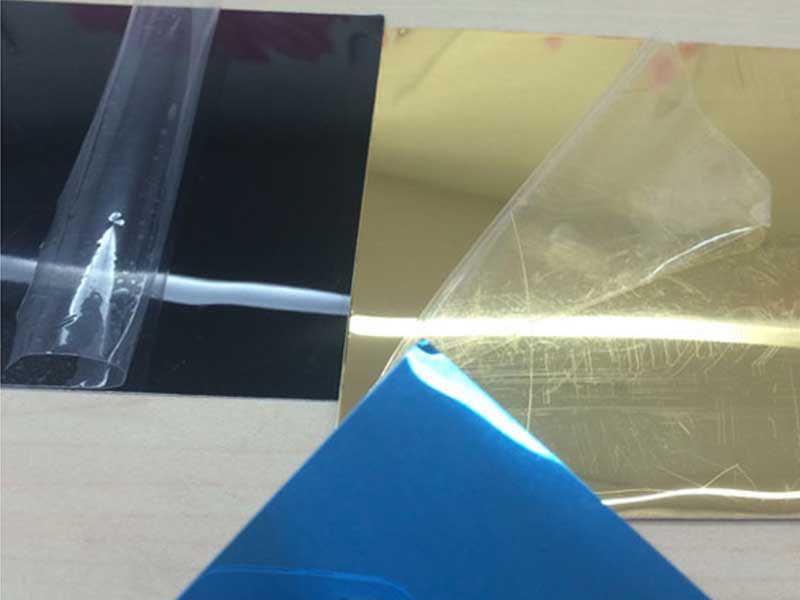

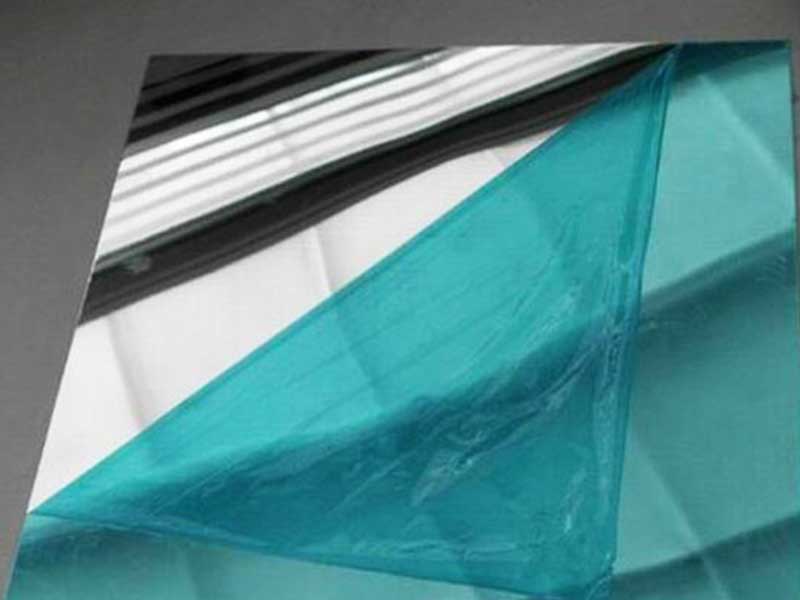

Mirror Finish: The mirror-like polish on these aluminum sheets not only elevates visual appearances but also aids in effacing scratches and wear, making them suitable for high-visibility applications considering their aesthetic appeal.

-

Embossed Texture: The embossed design enhances throw off non-slip properties, invaluable in flooring and walking surfaces. It reduces glare, improving safety in applications prone to reflectivity, such as automobiles and appliances.

-

Corrosion Resistance: Aluminum naturally resists oxidation. The thin film of aluminum oxide that forms on the surface increases durability in outdoor environments or areas with exposure to weather conditions.

-

Lightweight and Strong: With H-value temperings, these sheets maintain et classically desirable qualities of aluminum—combining lightweight construction—ideal for transport applications and strong enough for Structural frameworks requiring stability.

-

Chemical Resistance: Aluminum exhibits strong resistance to many chemicals, which enhances its usability in environments where spills or harsh cleaning procedures can affect other materials.

Diverse Applications

H12, H22, H14, and H24 temper mirror finish embossed aluminum sheets find appeal across an evolving range of industry sectors:

-

Transportation: Ideal for modern automotive designs requiring both an aesthetic edge and structural integrity, glossy finishes give enhanced visuals on vehicle bodies and interior surfaces like dashboards.

-

Construction: Frequently used in wall cladding, ceilings, and partitioning, these will improve building sustainability maintaining structural development as seen in the energy-efficient commercial fixtures.

-

Consumer Products: Seen utilized in a range of consumer appliances, encompassing those based on kitchen construction, home vehicles, and furniture designer stock, as each employs the blend of form and function brought via custom designs.

-

Signage and Displays: Engaging public displays and professional advertisements accomplish enhanced attraction through its mirrored surface catching light while embossed highlights catch movements in contrast.

-

Lighting Fixtures: In projects allowing for luxurious ambiance, decorative archival design, and feature lighting with as focal philosophy, it provides exemplary dispersion linking direct and ambient.

https://www.al-alloy.com/a/h12-h22-h14-h24-temper-mirror-finish-embossed-aluminum-sheet.html