Anodized aluminum sheet 1325

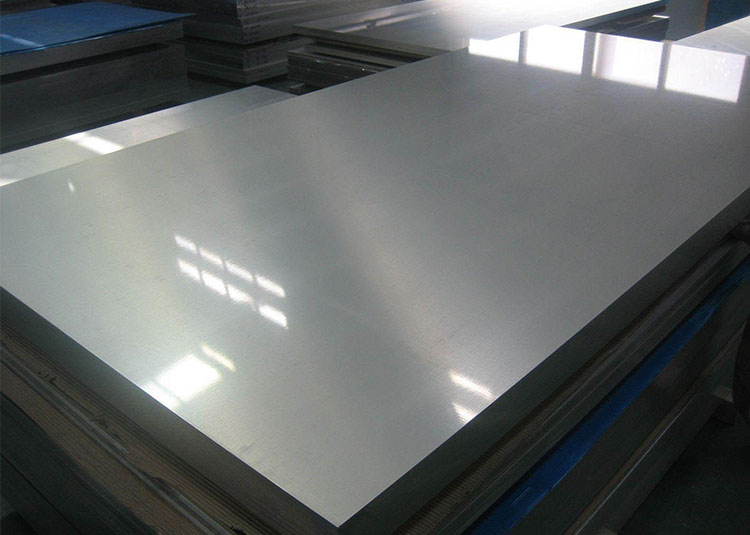

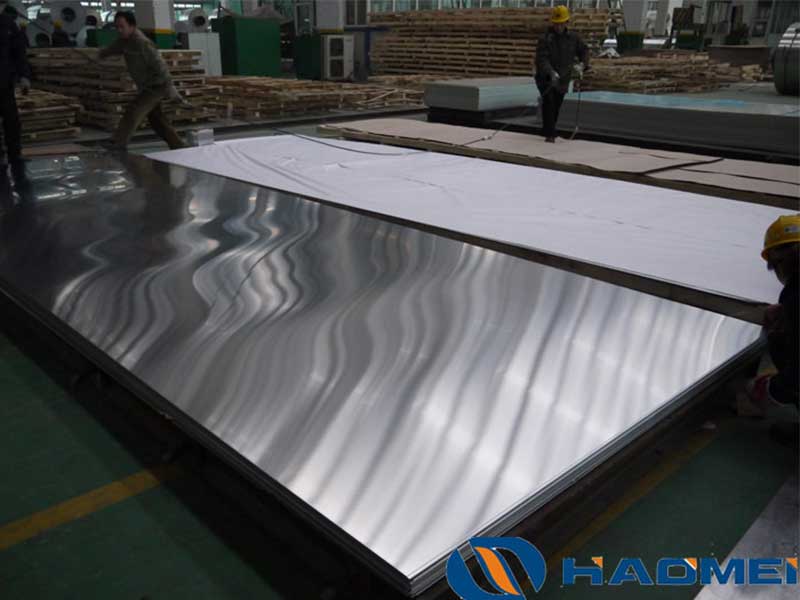

The anodized aluminum sheet 1325 stands out as a highly sought-after material across multiple industries, thanks to its unique properties and diverse applications. Anodization, a process that enhances the aluminum surface, offers improved corrosion resistance, increased durability, and an appealing aesthetic that makes it the ideal choice for many projects.

Features of Anodized Aluminum Sheet 1325

-

Corrosion Resistance: One of the primary advantages of anodized aluminum sheet 1325 is its exceptional resistance to corrosion. The anodizing process forms a thick, oxide layer on the aluminum surface, providing excellent protection against environmental factors such as moisture, chemicals, and UV light. This feature ultimately enhances the longevity and reliability of the material.

-

Aesthetic Appeal: Anodized aluminum sheet 1325 is available in a range of colors and finishes, creating a visually striking appearance that is perfect for architectural applications. This versatile finish not only looks great but also ensures that the surface will maintain its elegant appearance over time, reducing the need for repainting or refinishing.

-

Lightweight and Durable: Aluminum is naturally a lightweight material, and the anodizing process further strengthens this aluminum sheet, making it a robust option for various applications. Being lightweight, it facilitates ease of handling and installation while maintaining structural integrity.

-

Ease of Fabrication: With its excellent malleability, anodized aluminum sheet 1325 can be easily fabricated into different shapes and sizes, accommodating many project specifications. This adaptability makes it an ideal choice for manufacturers and architects who require bespoke solutions.

-

Environmentally Friendly: The anodization process is sustainable and environmentally friendly. Anodized coatings are non-toxic, and the aluminum substrate is recyclable, contributing to sustainable construction practices and eco-conscious projects.

Applications of Anodized Aluminum Sheet 1325

The versatility of anodized aluminum sheet 1325 leads to a wide range of applications across various industries:

1. Architectural Elements:

With its visually appealing finish and exceptional durability, anodized aluminum sheet 1325 is widely utilized in architectural design, including facades, window frames, and roofing. Architects appreciate its ability to withstand harsh weather conditions while providing an aesthetically pleasing look.

2. Interior Design:

In addition to external applications, this material is also favored by interior designers for use in decorative elements such as wall panels, ceilings, and cabinetry. The varied colors and finishes enhance any interior space.

3. Automotive Industry:

Lightweight yet strong, anodized aluminum sheet 1325 is increasingly used in automotive manufacturing. Its corrosion-resistant properties make it suitable for components exposed to various environmental conditions, ultimately boosting vehicle performance and longevity.

4. Electronics:

The electronics sector benefits from anodized aluminum sheet due to its exceptional thermal management properties and non-conductivity. It’s commonly used for housing in electronic devices, ensuring durability and thermal efficiency.

5. Manufacturing and Packaging:

From machinery components to attractive packaging materials, anodized aluminum sheet 1325 finds its place in manufacturing-industries. It not only adds a stylish look but also offers reliability and ease of production.

6. Furniture:

Modern furniture designers frequently utilize anodized aluminum sheet 1325 for creating lightweight and aesthetically pleasing furniture pieces. Its durability ensures a long lifespan while maintaining the desired style.

https://www.al-alloy.com/a/anodized-aluminum-sheet-1325.html