Aluminum plate metal 4x4

When it comes to material versatility in construction and crafting, few options are as beneficial as aluminum plate metal, particularly in the popular 4x4 size. Having become an essential staple in numerous industries, the aluminum plate stands out not just for its structural beauty and durability but also for the intriguing possibilities it opens up for both professional builders and passionate DIYers alike.

Embracing Nature and Strength

Aluminum is renowned for being lightweight yet incredibly strong, making it an appealing alternative to traditional materials. Think about it—what if you could construct strong frameworks or decorative features without the added weight that other metals carry? The aluminum plate metal 4x4 embodies this ethos perfectly. It allows craftsmen to build with strength while keeping projects manageable.

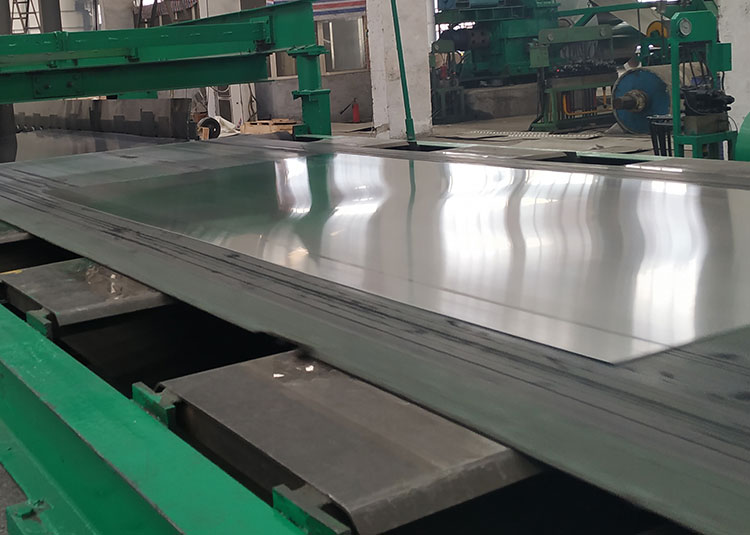

Working with 4x4 aluminum plates frequently highlights the material's inherent strengths and weaknesses. The rigidity offered by this size is excellent for applications demanding structural integrity, like machine bases or protective shielding. However, handling 4x4 plates presents unique challenges. Their significant weight necessitates specialized lifting equipment to prevent damage or workplace injuries. Furthermore, the larger surface area increases the potential for surface imperfections like scratches or dents during fabrication, transport, and storage, demanding extra care throughout the entire process. We often see issues with warping during the anodizing process due to uneven heating and cooling of such a large piece. Careful attention to material selection, including alloy type and temper, is crucial to minimizing these issues.

Beyond the physical handling, a consideration is the specific application for the 4x4 aluminum plate. The chosen alloy significantly impacts its final properties, such as corrosion resistance and strength-to-weight ratio. For example, a 6061 alloy might be perfect for general-purpose applications, while a 5052 alloy is preferable in corrosive environments. the customer's needs—the intended load-bearing capacity, environmental exposure, and required finish—is critical to selecting the appropriate plate and optimizing the manufacturing process to meet their exacting specifications and avoid costly rework or returns. We've learned that proactive communication with the customer about these factors upfront saves significant time and resources in the long run.

The pleasant experience of working with this metal is derived from its intrinsic qualities. Unlike steel, which can succumbs to rust over time, aluminum exhibits a high level of resistance to corrosion when exposed to various environmental stimuli. This means outdoor projects, from fence repairs to patio constructions, retain their aesthetic for years without cumbersome upkeep—a significant win for homeowners and commercial contractors.

The Art of Creation

As we dive into the myriad uses for aluminum plate 4x4, creativity blossoms. For artisans at heart, the option to mill, fabricate, or forge extraordinary art pieces, fixtures, and innovative solutions using this metal is monumental. Imagine designing elegant table bases, artistic sculptures, or even customized signage, all while leveraging the easy workability of aluminum.

Beginners and hobbyists also find solace in aluminum plate projects, as it welcomes experimentation. Cutting and machining the 4x4 plate can be achieved simply with the right tools and guidance. Clear-cutting patterns and impaired design come alive easily through various utilities and techniques—laser cutting, welding, and simple fastening yield results that resonate beauty and style.

Applications Beyond Imagination

The applications for aluminum plate metal are not just confined to artistic ventures; they extend to a realm of utilities that can serve industries such as automotive, aerospace, HVAC, and cookware design. From large-scale installations, like heat exchangers, to on-demand sprinkler systems, the lightweight nature of this metal offers unique solutions in transporting and implementing ideas that were once only limited in outline.

Tinkerers aware of difficult outdoor conditions, such as marine environments, will also appreciate aluminum's resilient nature in saltwater. A 4x4 aluminum plate is perfect for fabricating custom boat components—transom plates, brackets, and shell skins welcome designers who prioritize both longevity and minimal weight.

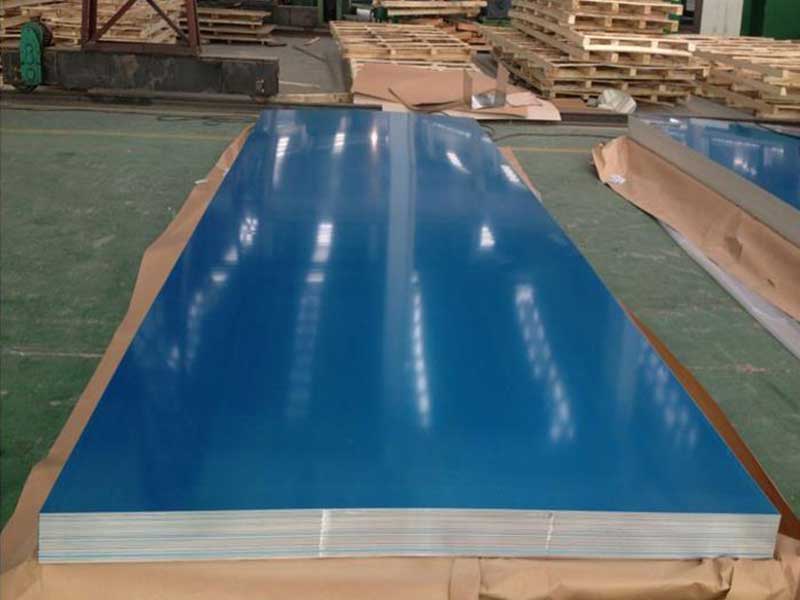

Finding Your Right Finish

Let’s not forget the creative cosmetic possibilities! Aluminum is receptive to different surface treatments, and for artisan or craftsmen looking to fine-tune their projects, choosing the right finish is crucial. Anodizing can elevate the aluminum with vibrant colors while protecting against damage. Brush finish casts shadows into precision work, bringing intricacy that demands admiration, all while retaining optimal integrity.

An Eco-Conscious Choice

Importantly, aluminum is regarded as an eco-friendly material. As a resource, it can be recycled repeatedly without degradation. By choosing aluminum plate metal 4x4 for your modern or traditional projects, you're not only embracing a versatile utility but also consciously contributing to sustainability and reduced environmental impact.